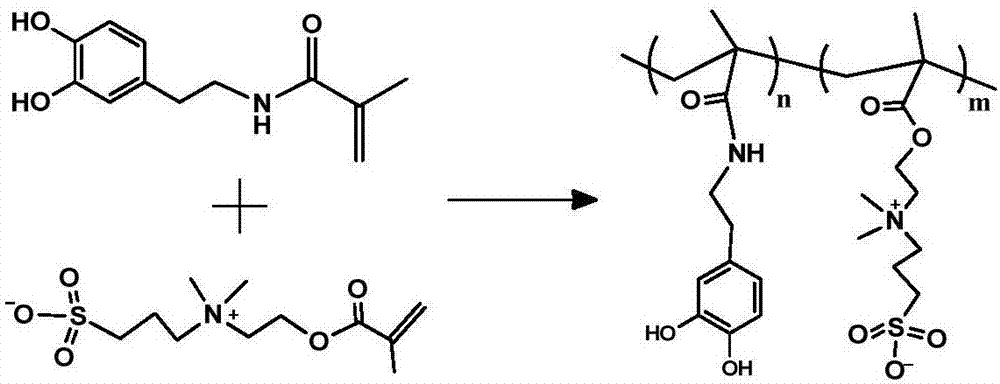

Polydopamine methacrylamide sulphobetaine and preparation method and application thereof

A technology of polydopamine methacrylamide sulfobeet and dopamine methacrylamide, which is applied in the field of material science and can solve the problems of low surface modification efficiency, harsh conditions, and complicated methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1, DMA

[0037] Add 10g of sodium tetraborate and 4g of sodium bicarbonate (used to protect the o-diphenol group) into 100mL of ultrapure water, and after passing through argon for 30 minutes, add 5g of dopamine hydrochloride, and then add 4.7mL of methacrylic anhydride, wherein First mix 4.7mL of methacrylic anhydride into 25mL of tetrahydrofuran, and then add it dropwise with a separatory funnel. In order to control the pH to be greater than 8, add 1mol / L sodium hydroxide solution dropwise, and constantly use pH test paper to detect the reaction. The reaction was carried out for 14 hours under an argon gas atmosphere. After the above reaction was carried out for 16 hours, the resulting suspension was washed twice with 50 mL of ethyl acetate, and the resulting aqueous solution was adjusted to a pH of about 2 with 6 mol / L, then extracted three times with 50 mL of ethyl acetate, and the organic phase was washed with anhydrous MgSO 4 After ...

Embodiment 2

[0038] The preparation of embodiment 2, PDMASB6.4

[0039] 50mL of ultrapure water and methanol with a volume ratio of 4:1 is used as a solvent, firstly add 0.5g of sodium tetraborate and 0.1g of sodium bicarbonate, and after passing argon for half an hour, add monomer SB and DMA, wherein SBMA and DMA The molar ratio was 6.4:1, and nitrogen gas was introduced for 15 minutes. After fully stirring, it was transferred to an oil bath at 60°C for reaction, and the reaction was stopped after 20 hours. After cooling, it was settled twice with 250 mL of ethanol, and the product was obtained after freeze-drying.

Embodiment 3

[0040] The preparation of embodiment 3, PDMASB1.6

[0041] 50mL of ultrapure water and methanol with a volume ratio of 1:1 is used as a solvent, firstly add 0.5g sodium tetraborate and 0.15g sodium bicarbonate, and after passing nitrogen for half an hour, add monomer SB and DMA, wherein SBMA and DMA mole The ratio is 1.6:1, and then nitrogen gas is introduced for 15 minutes. After fully stirring, it was transferred to an oil bath at 80°C for reaction, and the reaction was stopped after 12 hours. After cooling, it was settled twice with 250 mL of ethanol, and the product was obtained after freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

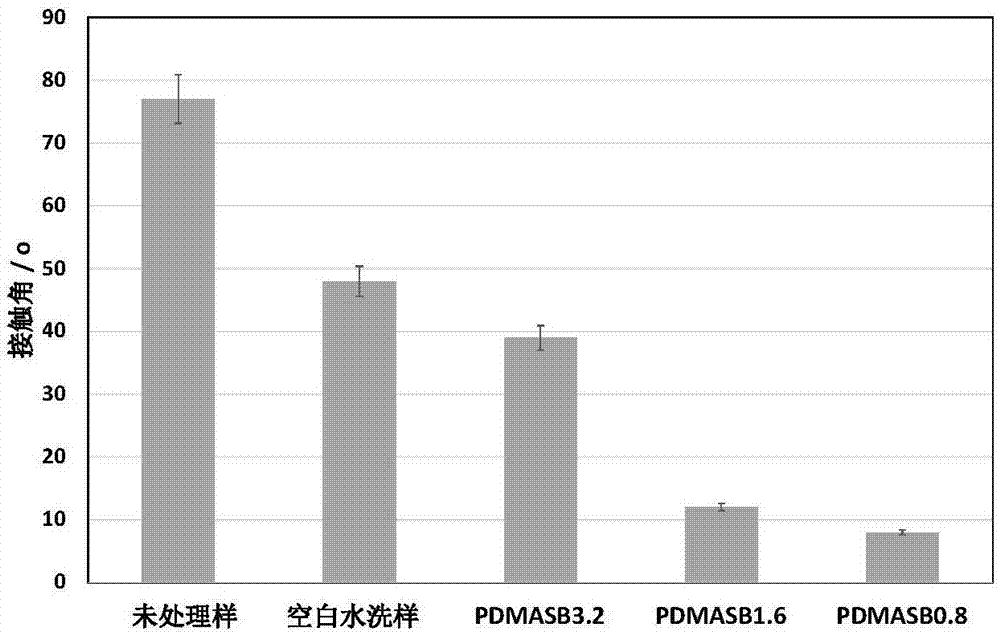

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com