Preparation method and application of magnetic 5A molecular sieve

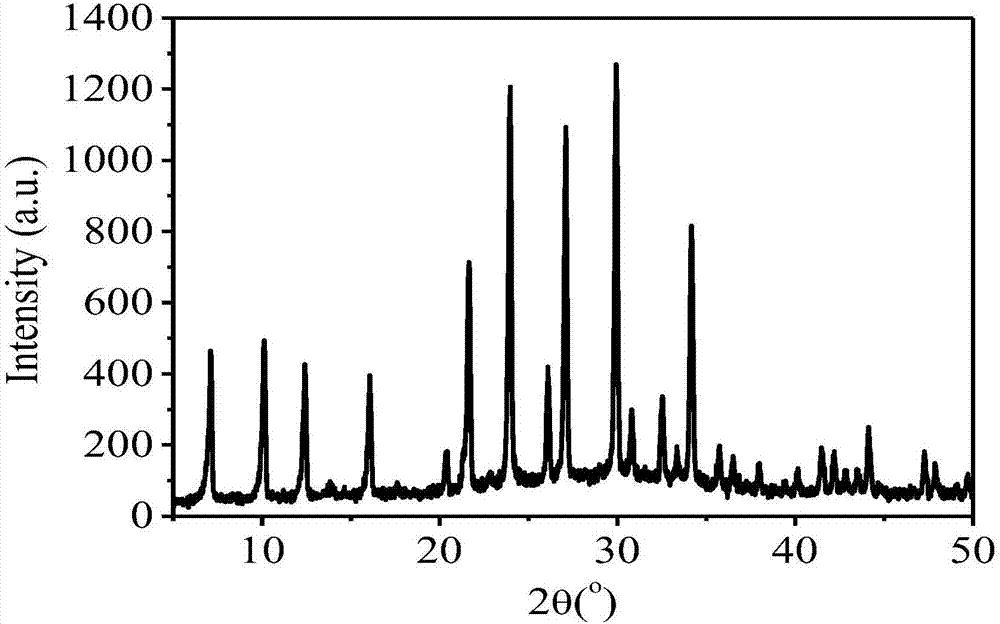

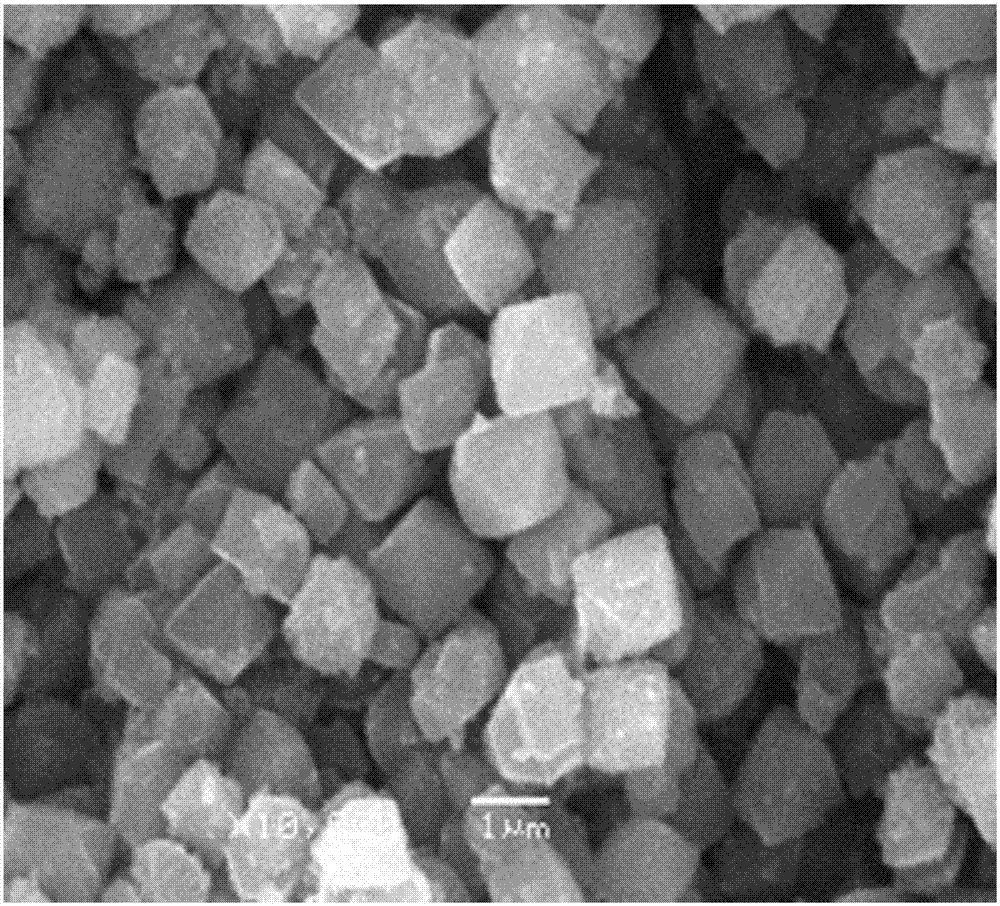

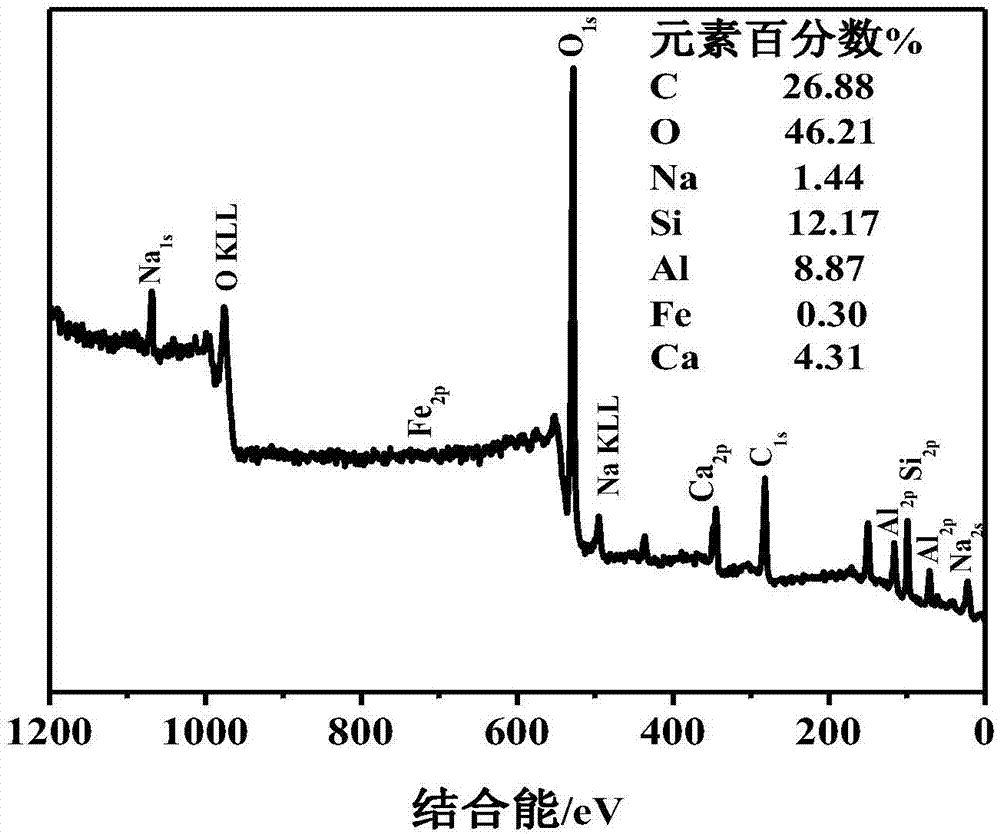

A molecular sieve and magnetic technology, which is applied in the field of preparation of magnetic 5A molecular sieves, to achieve the effect of uniform particle size, high crystallinity and regular crystal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of magnetic 5A molecular sieves in this embodiment comprises the following steps:

[0032] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 25g FeCl per liter of distilled water 2 4H 2 O, add 62.5g FeCl 3 ·6H 2 O; under the condition of nitrogen protection, the reaction was carried out in ultrasonic wave, and the temperature was raised to 75 °C at the same time, and NH was added after constant temperature 3 ·H 2 O (add 125 mL NH per liter of distilled water 3 ·H 2 (2) to obtain a solid-liquid mixture after continuing to react for 20min, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, and then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 65 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

[0033] Step 2. Dissolve sodium metaa...

Embodiment 2

[0039] The preparation of magnetic 5A molecular sieves in this embodiment comprises the following steps:

[0040] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 18.75g FeCl per liter of distilled water 2 4H 2 O, add 56.25g FeCl 3 ·6H 2 O, under the condition of nitrogen protection, the reaction was carried out in ultrasonic wave, and the temperature was raised to 75 °C at the same time, and NH was added after constant temperature 3 ·H 2 O (add 125 mL NH per liter of distilled water 3 ·H 2 (0), continue to react for 20min to obtain a solid-liquid mixture, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 65 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

[0041] Step 2. Dissolve sodium metaaluminat...

Embodiment 3

[0046] The preparation of magnetic 5A molecular sieves in this embodiment comprises the following steps:

[0047] Step 1, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O added to distilled water, FeCl 2 4H 2 O, FeCl 3 ·6H 2 The amount of O and distilled water added is 31.25g FeCl per liter of distilled water 2 4H 2 O, add 68.75g FeCl 3 ·6H 2 O; under the condition of nitrogen protection, the reaction was carried out in ultrasonic wave, and the temperature was raised to 85 °C at the same time, and NH was added after constant temperature 3 ·H 2 O (add 125 mL NH per liter of distilled water 3 ·H 2 (2) to obtain a solid-liquid mixture after continuing to react for 20min, after the natural cooling of the solid-liquid mixture, utilize a magnet to adsorb the magnetic substance in the solid-liquid mixture, and then repeatedly wash the magnetic substance obtained by adsorption, at a temperature of 75 After drying at ℃ for 5h, the magnetic Fe 3 o 4 ;

[0048]Step 2. Dissolve sodium me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com