A parallel structure dual-motor electric power steering system and power steering method

An electric power steering, dual-motor technology, applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve the problems of large space occupation, affecting handling stability, and increasing warranty cost, achieving high working reliability and saving. Layout space, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

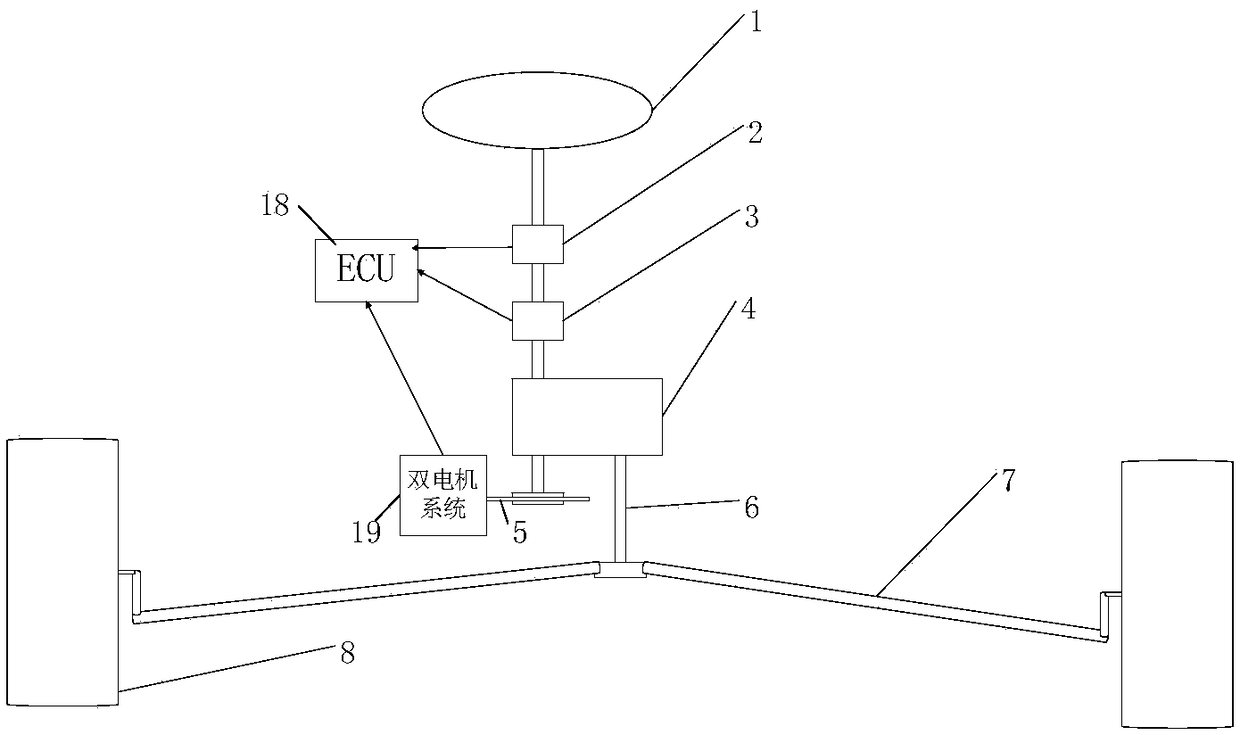

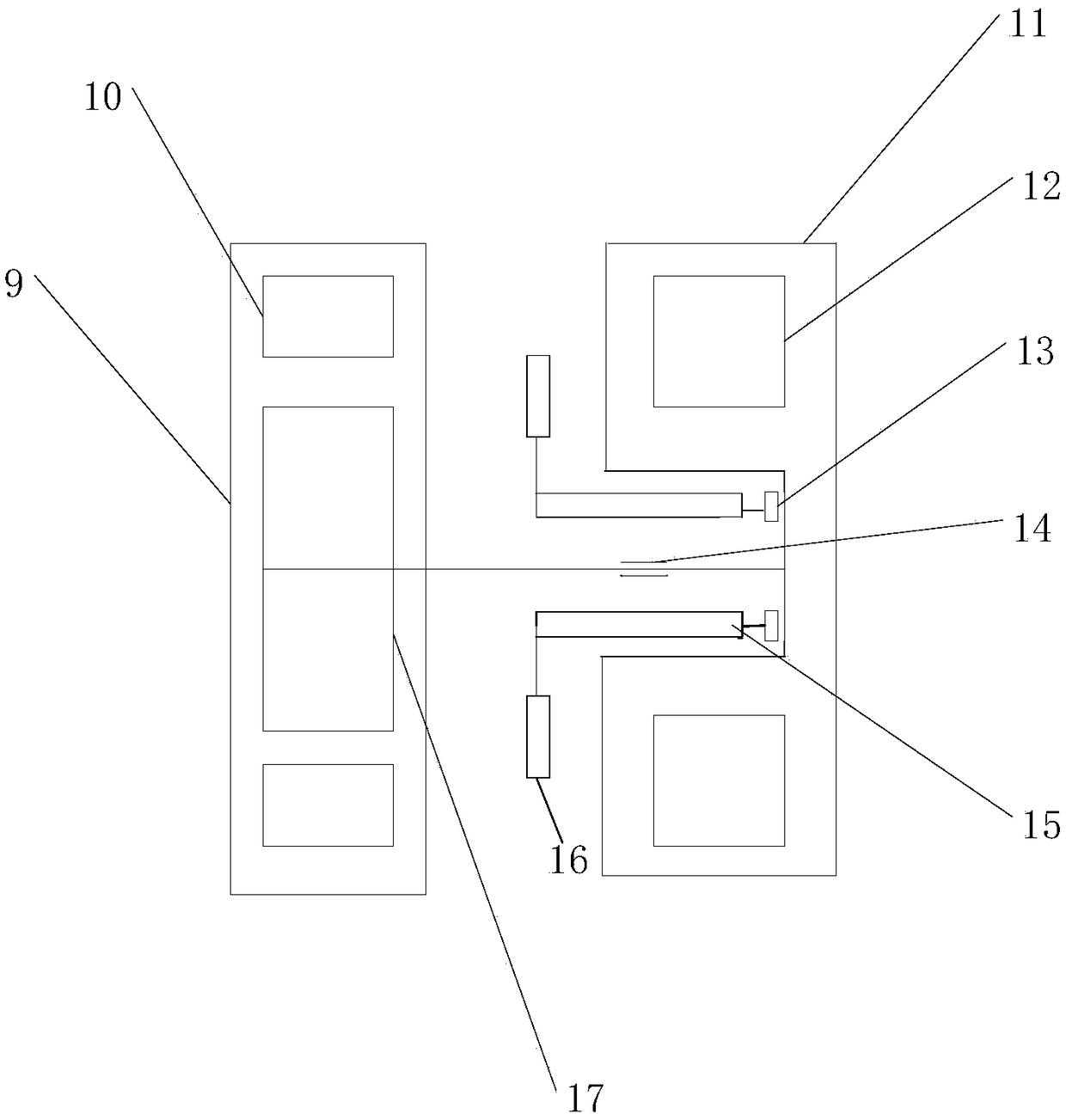

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 , the dual-motor electric power steering system of the present invention includes a steering wheel 1, a steering wheel angle and position sensor 2, a steering wheel torque sensor 3, a steering gear 4, a steering gear reduction mechanism 5, a steering rocker arm 6, and a steering tie rod 7 , a dual motor system 19, a vehicle speed sensor and an electronic control unit (ECU) 18. The vehicle speed sensor is set on the vehicle body; the steering wheel angle and position sensor 2 is set under the steering wheel 1 for real-time acquisition of the position and angle signal of the steering wheel 1, and the steering wheel torque sensor 3 is set under the steering wheel 1 for real-time The torque of the steering wheel 1 is collected; the steering wheel 1 is also connected to the steering gear 4 .

[0026] The two wheels 8 are connected to the steering rocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com