Aramid paper honeycomb composite floor with strong sound insulation performance and preparation method thereof

A technology of composite flooring and aramid paper, applied in chemical instruments and methods, flat products, and other household appliances, can solve the problem that sound cannot achieve high-efficiency sound absorption, achieve low density, high weighted sound insulation, and reduce braking The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation formula of porous nitrile rubber in step 2 among the present invention is: the nitrile raw rubber of 100phr, the carbon black of 20~30phr, promotor, 5~10phr zinc oxide (ZnO), 5~10phr urea, 10~15phr plasticizer , 1~5phr anti-aging agent, vulcanizing agent, 10~15phr foaming agent.

[0031] The accelerator in the present invention is composed of 0.5~1.5phr 2-mercaptobenzothiazole (M), 0.2~0.4phr zinc diethyldithiocarbamate (ZDC), and 2~5phr stearic acid (HSt); The plasticizer is diisononyl phthalate (DINP); the anti-aging agent is 4010NA; the vulcanizing agent is 1~5phr sulfur (S) and 1~5phr dicumyl peroxide (DCP) ; The blowing agent is azodicarbonamide (AC).

[0032] Porous acrylonitrile-butadiene rubber in the present invention is prepared according to the following method:

[0033] Step a: Add raw nitrile rubber to an internal mixer at 120~150°C, then mix carbon black, accelerator, stearic acid, zinc oxide and plasticizer evenly and add in batches, kne...

Embodiment 1

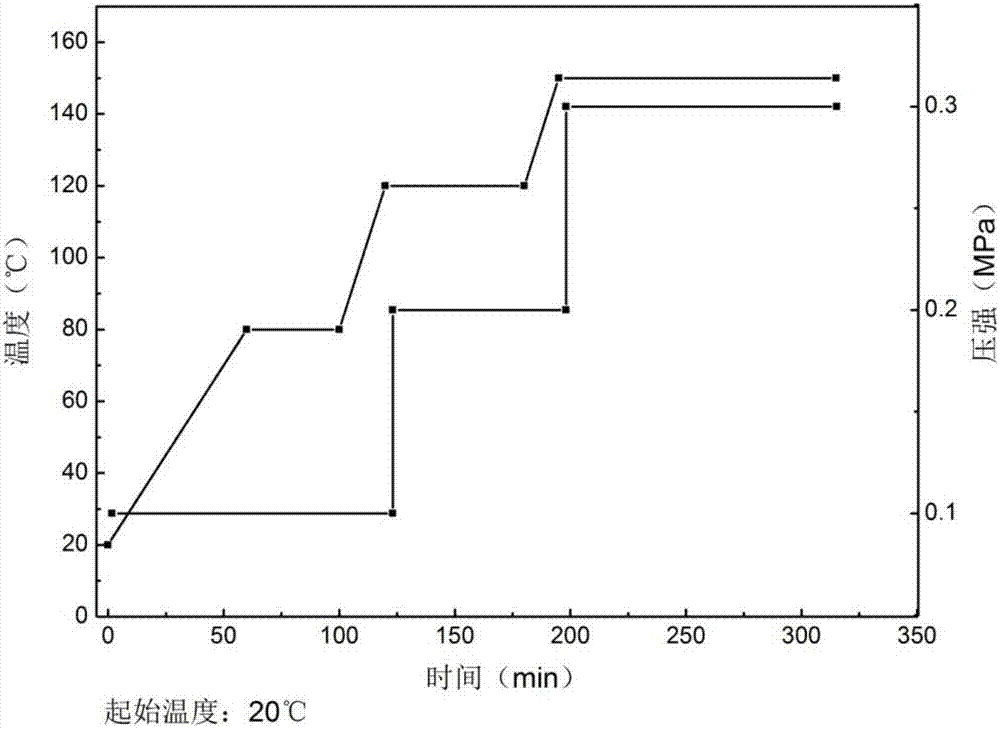

[0038] Step 1: Put the double-layer glass fiber phenolic prepreg into a hot press for curing to form a prepreg cured sheet;

[0039] Step 2: preparing porous nitrile rubber;

[0040] Step 3: Spread the release agent evenly on the surface of the smooth aluminum plate, the amount of release agent is 60ml / m 2 After 5 minutes, use epoxy glue as an adhesive to bond the prepreg cured sheet, porous nitrile rubber and aramid paper honeycomb in sequence, and then press the aluminum plate on the composite floor to form a prefabricated honeycomb floor.

[0041] Step 4: Put the prefabricated honeycomb floor made in step 3 into a hot press, and cure it for 80 minutes at a curing temperature of 50° C. and a curing pressure of 0.2 MPa to obtain a strong sound-insulating aramid paper honeycomb composite floor.

[0042] The preparation formula of porous nitrile rubber in step 2 in embodiment 1 is: 100phr nitrile raw rubber, 25phr carbon black, accelerator, 8phr zinc oxide (ZnO), 6phr urea, 10ph...

Embodiment 2

[0049] Step 1: Put the double-layer glass fiber phenolic prepreg into a hot press for curing to form a prepreg cured sheet;

[0050] Step 2: preparing porous nitrile rubber;

[0051] Step 3: Spread the release agent evenly on the surface of the smooth aluminum plate, the amount of release agent is 80ml / m 2 After 5 minutes, use epoxy glue as an adhesive to bond the prepreg cured sheet, porous nitrile rubber and aramid paper honeycomb in sequence, and then press the aluminum plate on the composite floor to form a prefabricated honeycomb floor.

[0052] Step 4: Put the prefabricated honeycomb floor made in step 3 into a hot press, and cure it for 80 minutes at a curing temperature of 50° C. and a curing pressure of 0.2 MPa to obtain a strong sound-insulating aramid paper honeycomb composite floor.

[0053] The preparation formula of porous nitrile rubber in step 2 in embodiment 2 is: 100phr nitrile raw rubber, 20phr carbon black, accelerator, 10phr zinc oxide (ZnO), 5phr urea, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com