Zero-formaldehyde release water-borne polyurethane adhesive LVL (Laminated Veneer Lumber) and manufacturing method thereof

A water-based polyurethane glue and water-based polyurethane technology, applied in the field of wood processing, can solve the problems of insufficient flexibility and easy breakage of plywood, and achieve the effect of soft and flexible glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] 1. Material sorting: select poplar veneer with a thickness of 1.2mm as the core board of plywood, control the moisture content within 14%, separate the loose side and tight side of the veneer, and make a good mark. Select Okoume's veneer as a backup board.

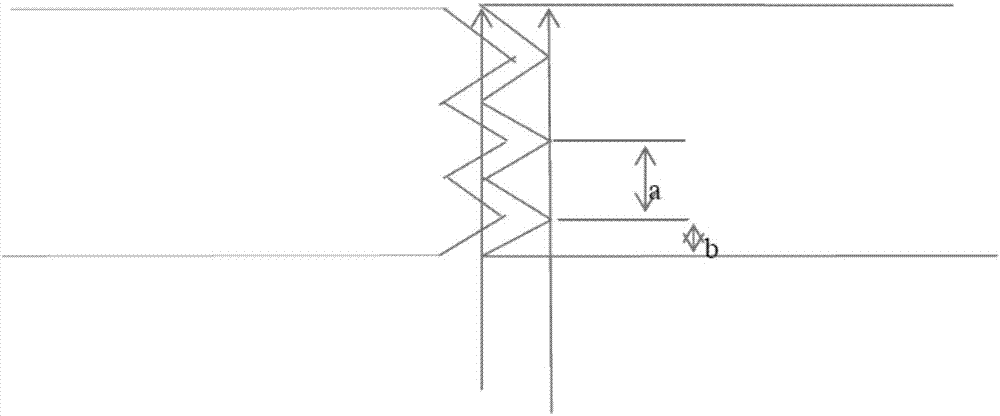

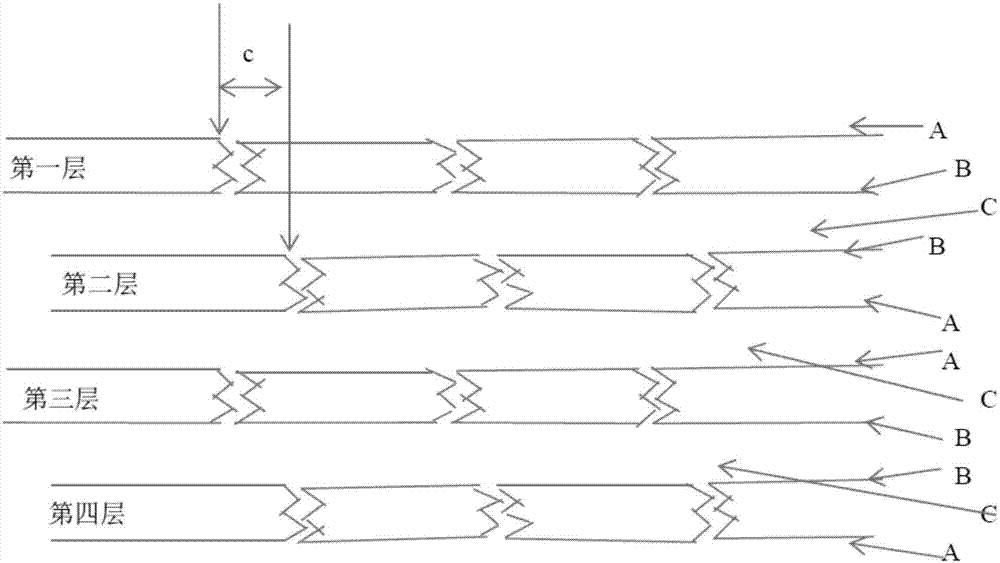

[0041] 2. End cutting teeth: Cut the sorted core plate into an equilateral triangle with the side length not less than 40mm. The edge is cut into half teeth, the details are as attached figure 1 as shown, figure 1 The distance a in the middle is the side length 40mm of the equilateral triangle incisor, b is half of the side length, and the half side length is 20mm.

[0042] 3. Glue adjustment: Weigh 40kg of aromatic water-based polyurethane-acrylic resin (produced by Water-based Ketian, model: WR11), 20kg of white ore powder (Guangzhou Fujian Material Jiaoling Refining Co., Ltd., model: CC-1000), Put 38kg of water into the bucket of the disperser, add 2.0kg of isocyanate (BASF, model: M20S) at a speed of 500r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com