Composite aluminum rim and manufacturing method thereof

A manufacturing method and technology of composite aluminum, applied in the direction of wheel manufacturing, wheels, vehicle parts, etc., can solve the problems of difficult to meet the requirements of high-quality vehicles, difficult to manufacture complex-shaped rims, and high prices of aluminum alloy rims, and to improve the quality level. , to ensure stability and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

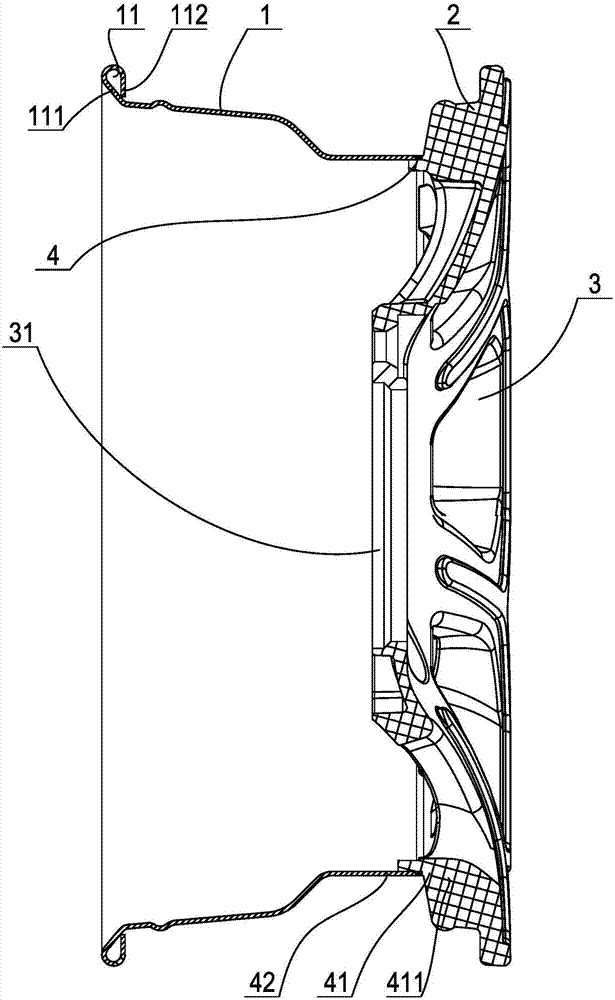

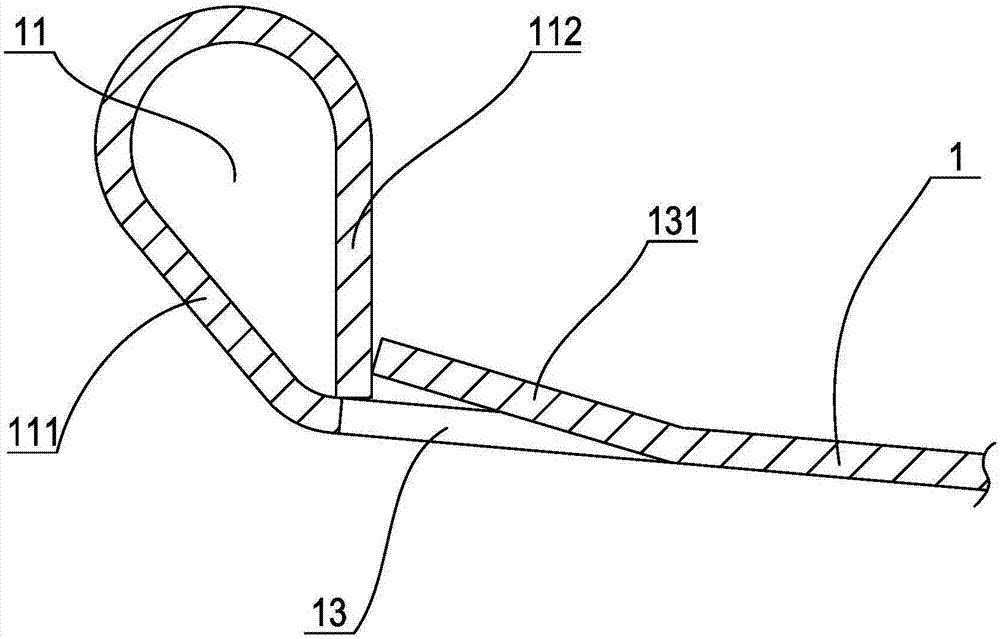

[0040] Embodiment 1: as figure 1 As shown, a composite aluminum rim includes a left ring body 1 and a right ring body 2 coaxially arranged side by side, the left ring body is a cylindrical member made by a stamping forming process, and a web is arranged on the right ring body 3. The right ring body and the web are made of an integrated structure through aluminum alloy die-casting process. Similar to the right ring body, the left ring body is also made of aluminum alloy. A connection part 4 is provided on the left side of the right ring body, and the connection part can be an integral structure formed by die-casting with the right ring body, or the connection part can also adopt such as figure 2 , Figure 4 In the structure shown, the connection part includes an embedded section 41 connected to the right coil body, and a welding section 42 protruding from the right coil body. The connection part is made by roll forming process, thereby forming a cylindrical structure with two...

Embodiment 2

[0047] Embodiment 2: A manufacturing method of a composite aluminum rim, which is suitable for manufacturing the composite aluminum rim as described in Embodiment 1, specifically includes the following steps:

[0048] a. Process the cylindrical left ring body through the stamping process, and the two ends of the left ring body are opened, and the left ring body should be made of aluminum alloy. Of course, we can also form a curling on the left end edge of the left ring body to the outer circumferential surface of the left ring body through the curling process, so as to improve the rigidity and strength of the left ring body;

[0049] b. A rectangular aluminum plate is prepared, the rectangular aluminum plate has two short sides and two long sides, and a number of rectangular notches are punched on one of the short sides of the rectangular aluminum plate by a stamping forming process, so that between two adjacent rectangular notches Form the convex rectangular sawtooth, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com