Piezoelectric ejection printing head and printing device provided with same

A piezoelectric jetting and printing head technology, applied in the field of printing devices and piezoelectric jetting printing heads, can solve the problems affecting the overall deformation of the laminated piezoelectric ceramics, reducing the printing head jetting accuracy, contusion and collapse of the edges and corners of the ceramics, etc. Low cost of use, accurate jet printing action, and the effect of avoiding extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

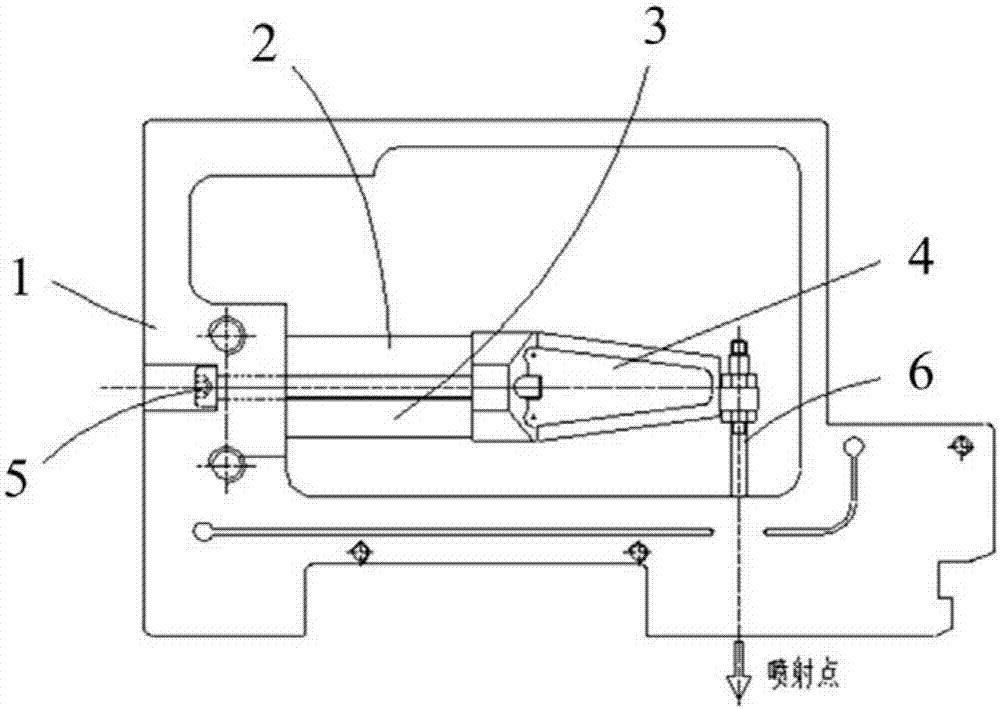

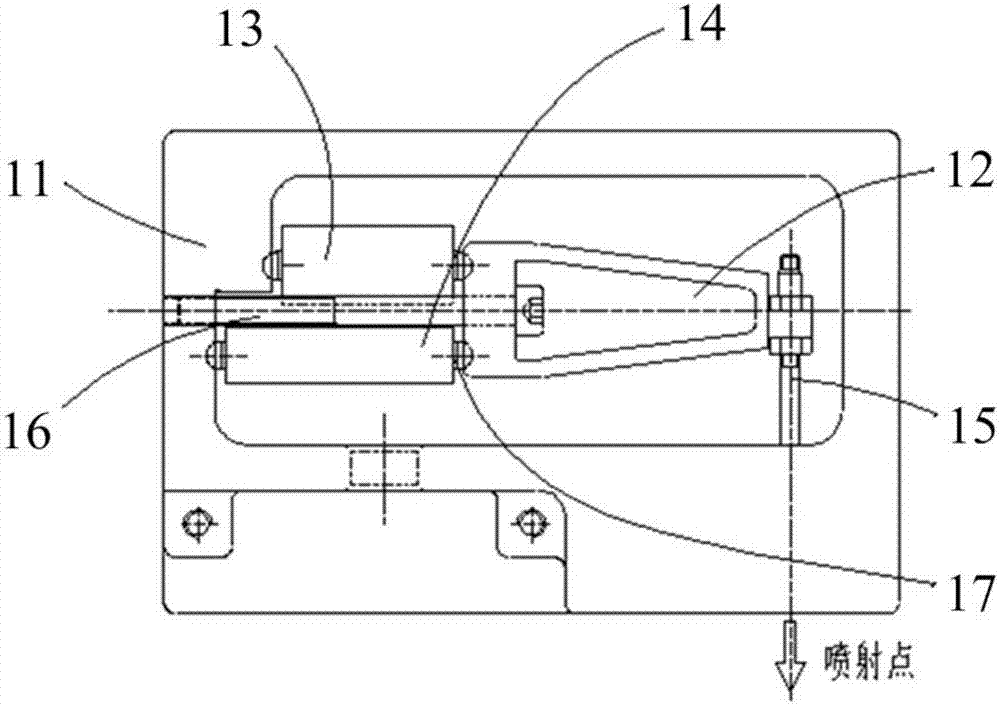

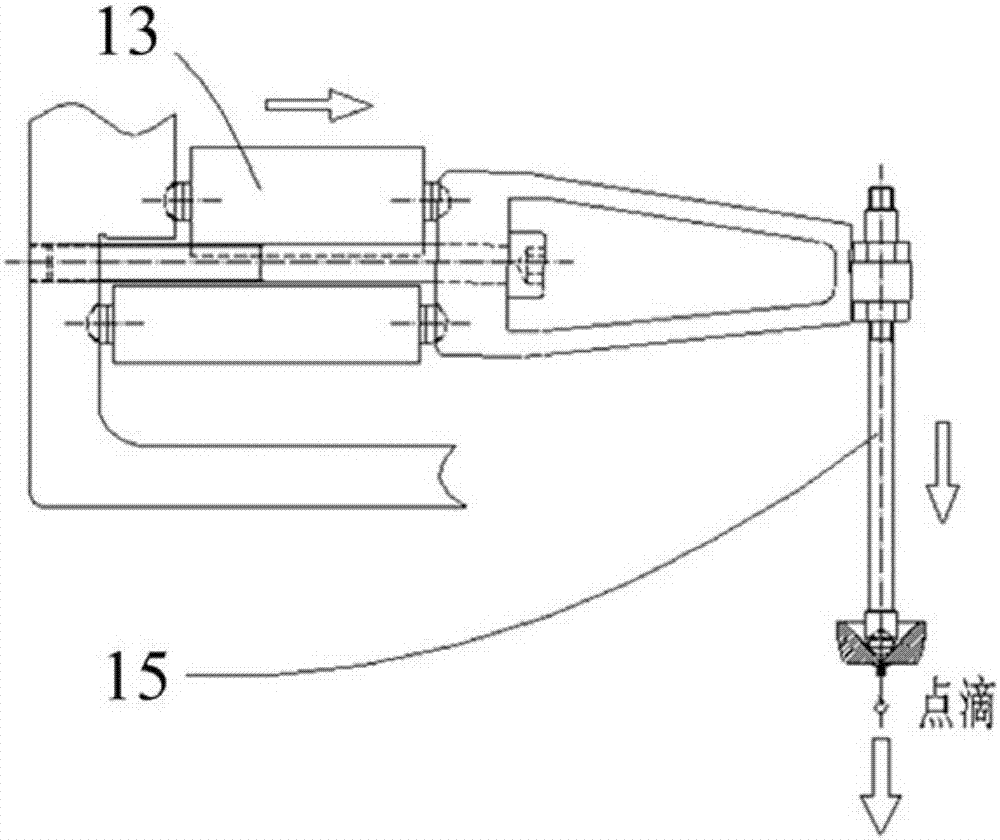

[0028] In one aspect, the present invention provides a piezoelectric jet printing head, such as figure 2 As shown, it includes a valve body 11, a displacement amplification mechanism 12, an upper piezoelectric ceramic 13, a lower piezoelectric ceramic 14 and a striker 15, wherein:

[0029] The displacement amplifying mechanism 12 is arranged inside the valve body 11 through the fixed rod 16, and the upper and lower piezoelectric ceramics 14 are respectively arranged above and below the fixed rod 16, and one side of the upper and lower piezoelectric ceramics 14 is connected to the valve body through a ceramic protrusion 17. On the inner wall of the valve body 11, the other side of the upper and lower piezoelectric ceramics 14 is connected to both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com