Tunnel kiln

A tunnel furnace and furnace body technology, which is applied in the field of tunnel furnaces, can solve the problems of reducing the heating efficiency of tunnel furnaces, heat waste, and the inability to place too many heating parts, and achieve the effects of improving heat utilization, reducing energy consumption, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

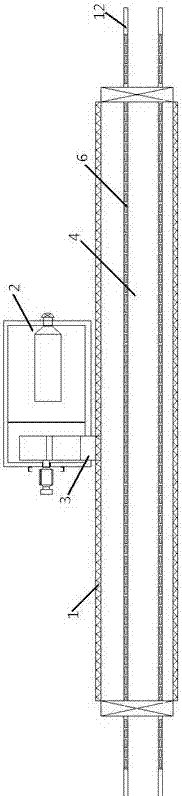

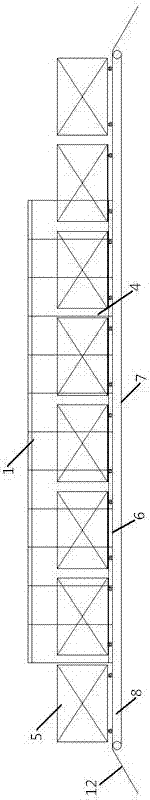

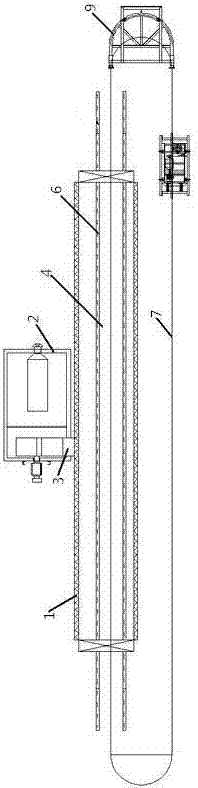

[0026] see Figure 3-Figure 4 , a tunnel furnace, comprising a furnace body 1, the outside of the furnace body 1 is provided with a heat supply device 2 using natural gas as a heat source, and the heat supply device 2 communicates with the inside of the furnace body 1 through a heat supply pipeline 3, so The furnace body 1 is provided with a workpiece transmission device 4 inside, and the workpiece transmission device 4 includes a truck 5 provided with multi-layer trays and a track 6 that is convenient for the truck 5 to walk. 5 has a slightly wider chute at the bottom of the pulley, and an annular suspension rail 9 is arranged above the truck 5. The suspension rail 9 wraps one side of the furnace wall of the tunnel furnace, and the continuously variable speed motor that provides power for the suspension rail 9 is installed in the On the track of the suspension rail 9 outside the furnace, catenary push rods 10 are evenly distributed on the suspension rail 9, and a stop bar 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com