Environmental protection coating of SiCf/SiC composite material guider blade and preparation method of environmental protection coating

A composite material and protective coating technology, which is applied in the direction of metal material coating process, coating, mechanical equipment, etc., can solve the problem that the environmental protection coating cannot be used for a long time, and achieve a wide range of temperature applications, wide adjustable range, Effect of Preventing Amorphous Reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

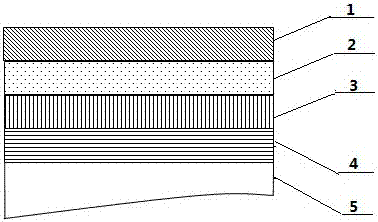

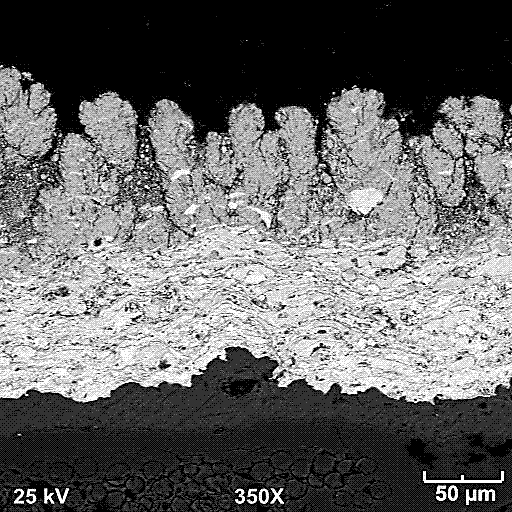

[0027] A certain type of aero-engine SiC f / SiC composite deflector vane 5 with a length of 600 mm, a width of 200 mm, and a thickness of 10 mm. Adopt the method provided by the invention to prepare Si bonding layer 4 / mullite transition layer 3 / Yb 2 SiO 5 Environmental barrier layer 2 / La 2Zr 2 o 7 Thermal barrier layer 1, the coating is composed of bonding layer, transition layer, environmental barrier layer and thermal barrier layer, all using PS-PVD equipment. First, the substrate is preheated with a spray gun, and the preheating temperature is 1000°C, and then the coating is prepared according to the following four steps.

[0028] Step 1: Preparation of Si Adhesive Layer 4

[0029] The powder raw material is high-purity silicon powder, the purity is 99.99%, and the powder particle size is 5-38 μm; the spraying speed is 1000 mm / s, spraying 5 times, and the coating thickness reaches 20 μm; the spraying process parameters of the Si bonding layer are: the vacuum degree is...

Embodiment 2

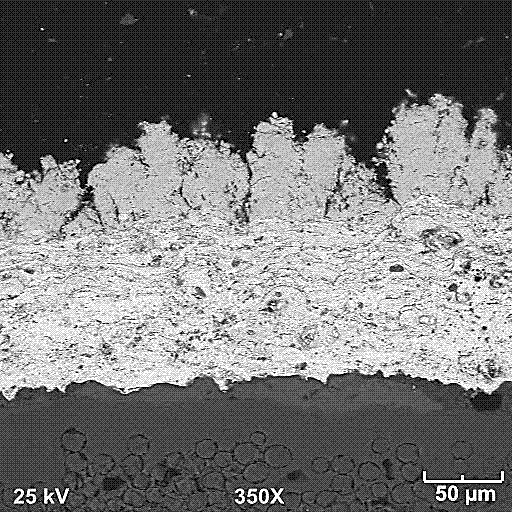

[0037] A certain type of aero-engine SiC f / SiC composite deflector vane 5 with a length of 600 mm, a width of 200 mm, and a thickness of 10 mm. Adopt the method provided by the invention to prepare Si bonding layer 4 / mullite transition layer 3 / Yb 2 SiO 5 Environmental barrier layer 2 / La 2 Zr 2 o 7 Thermal barrier layer 1, the coating is composed of bonding layer, transition layer, environmental barrier layer and thermal barrier layer, all using PS-PVD equipment. First, the substrate is preheated with a spray gun, and the preheating temperature is 1090°C, and then the coating is prepared according to the following four steps.

[0038] Step 1: Preparation of Si Adhesive Layer 4

[0039] The powder raw material is high-purity silicon powder, the purity is 99.99%, and the powder particle size is 5-38 μm; the spraying speed is 1000 mm / s, spraying 7 times, and the coating thickness reaches 50 μm; the spraying process parameters of the Si bonding layer are: the vacuum degree i...

Embodiment 3

[0047] A certain type of aero-engine SiC f / SiC composite deflector vane 5 with a length of 600 mm, a width of 200 mm, and a thickness of 10 mm. Adopt the method provided by the invention to prepare Si bonding layer 4 / mullite transition layer 3 / Yb 2 SiO 5 Environmental barrier layer 2 / La 2 Zr 2 o 7 Thermal barrier layer 1, the coating is composed of bonding layer, transition layer, environmental barrier layer and thermal barrier layer, all using PS-PVD equipment. First, the substrate is preheated with a spray gun, and the preheating temperature is 1200°C, and then the coating is prepared according to the following four steps.

[0048] Step 1: Preparation of Si Adhesive Layer 4

[0049] The powder raw material is high-purity silicon powder, the purity is 99.99%, and the powder particle size is 5-38 μm; the spraying speed is 1000 mm / s, spraying 6 times, and the coating thickness reaches 35 μm; the spraying process parameters of the Si bonding layer are: the vacuum degree i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com