Intelligent fully-automatic detector for transparent glass bottles

A glass bottle, fully automatic technology, used in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of difficult specifications, low detection accuracy, limited space in the production workshop, etc., and achieves a large range of adjustable specifications. , The effect of high detection accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described

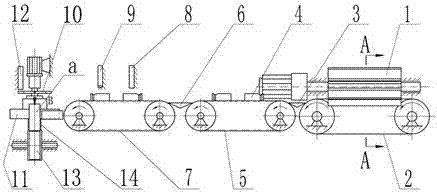

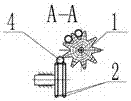

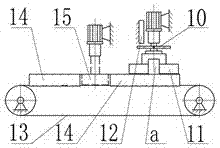

[0036] as attached figure 1 , 2 In the initial inspection and separation device shown, the horizontal toothed roller 1 and the double-bridge conveyor belt 2 are arranged in parallel, and the glass bottle 4 rolls from the hobbing of the horizontal toothed roller 1 onto the double-bridge conveyor belt 2, and the double-bridge conveyor belts 2, 5, and 7 are respectively Tensioned on the pulley, the double bridge conveyor belt 2, 5, 7 is set in three stages, the movement speed of the next stage double bridge conveyor belt 5 or 7 is greater than the running speed of the upper stage double bridge conveyor belt 2 or 5, and the double bridge conveyor belt 2 A bridge plate 3 is set between the conveyor belts 5 and 5, and a bridge plate 6 is set between the double-bridge conveyor belts 5 and 7. The pulley can drive the double-bridge conveyor belts 2, 5, and 7 to rotate, and the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com