Continuous potato cleaning and peeling integrated machine

A potato and all-in-one machine technology, which is applied in the peeling of vegetables or fruits, electromechanical devices, and control of mechanical energy. It can solve the problems of unclean cleaning, inability to adjust the motor speed, and poor peeling effect, and achieve accurate and convenient speed regulation. Operation, convenient and fast collection of slag water, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

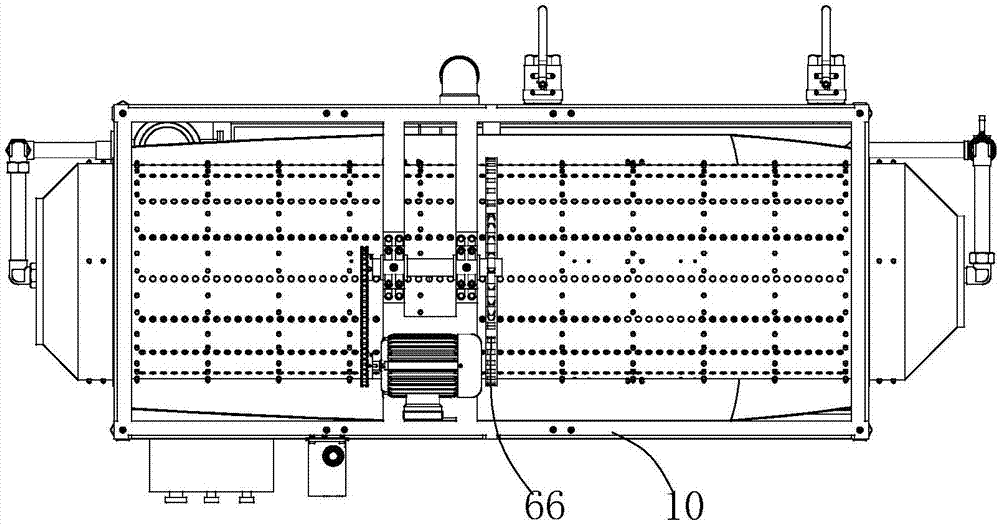

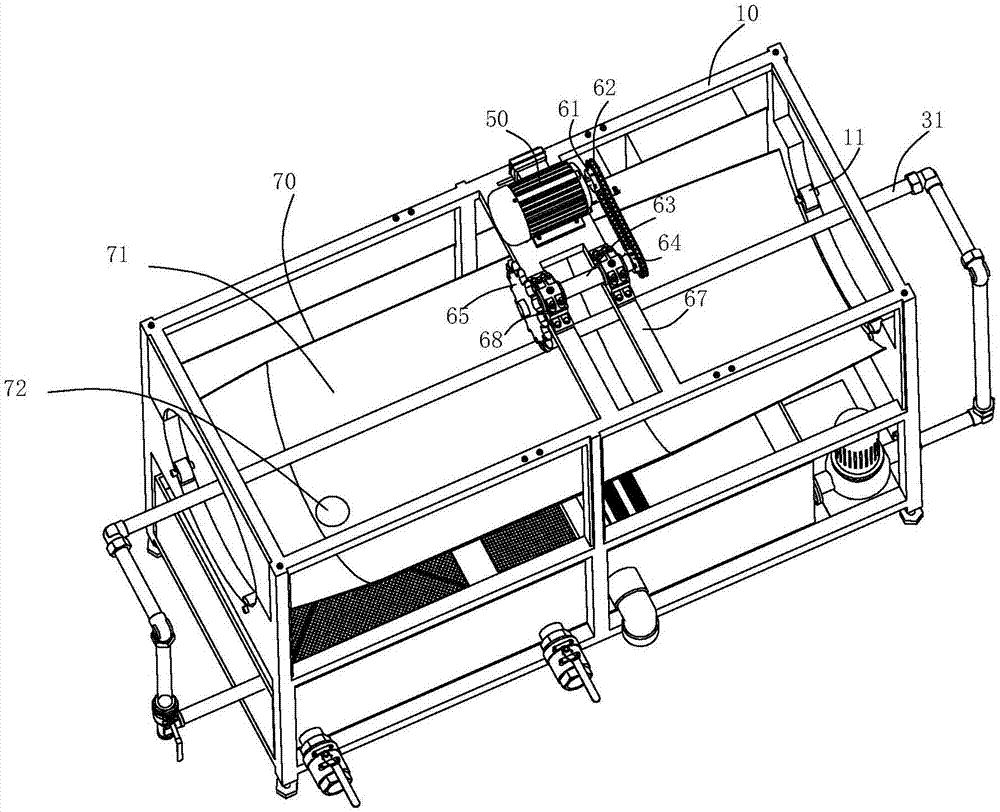

[0038] refer to Figure 1-8 , a continuous potato cleaning and peeling machine, including a frame 10, and a peeling mechanism, a cleaning mechanism and a power mechanism respectively installed on the frame 10;

[0039] Peeling mechanism comprises cylinder 21, and cylinder 21 is provided with the cavity 211 that penetrates along axial direction, and one end of described cavity 211 is provided with feed port 212, and the other end is provided with discharge port 213, and on the inner wall of cylinder 21 A brush 22 for peeling and a water outlet hole 214 for the drum are provided;

[0040] The cleaning mechanism includes a spray pipe 31 installed in the cavity 211;

[0041] The power mechanism includes a frequency converter 40, a motor 50 and a transmission mechanism. The output end of the frequency converter 40 is connected to the input end of the motor 50, and the output end of the motor 50 is connected to the drum through the transmission mechanism.

[0042] As a preferred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com