Simulation test device for wet desulphurization chimney

A test device, wet desulfurization technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost, difficult data comparison and analysis, and low value of theoretical research, so as to achieve the safety of simulation test, reduce the cost of test, and have the advantages of simulated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

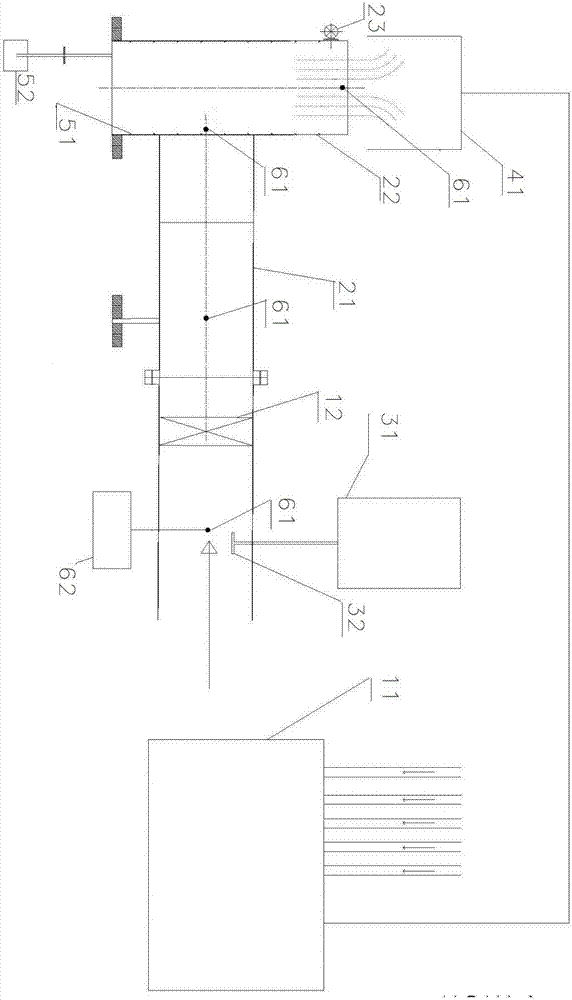

[0024] figure 1 is an embodiment of the present invention.

[0025] refer to figure 1 , The wet desulfurization chimney simulation test device of the present invention includes a smoke exhaust device, an air flow device, a spray device, a waste gas collection device, a condensate collection device and a central control system.

[0026] The smoke exhaust device comprises a horizontal flue 21 and a vertical flue 22 lined with an anti-corrosion material, and the vertical flue 22 is vertically arranged at the end of the horizontal flue 21 for simulating an actual chimney; the height of the vertical flue 22 is the same as that of the actual The chimney height ratio is 1:40, and the diameter ratio of the vertical flue 22 and the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com