Drive axle lubricant external circulation cooling system

A technology of cooling system and lubricating oil, applied in the direction of gear lubrication/cooling, engine lubrication, lubricating parts, etc., can solve the problem of high cost, large space for the arrangement of the drive axle assembly, inability to protect the drive axle assembly and cooling system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

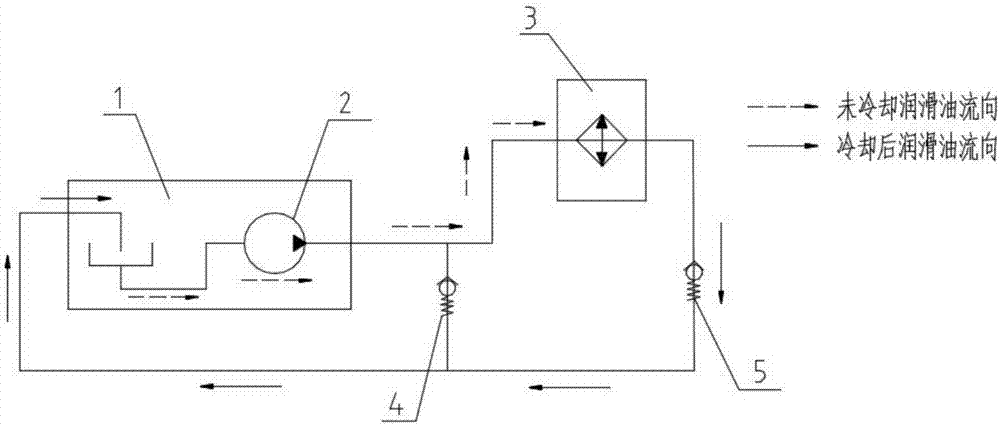

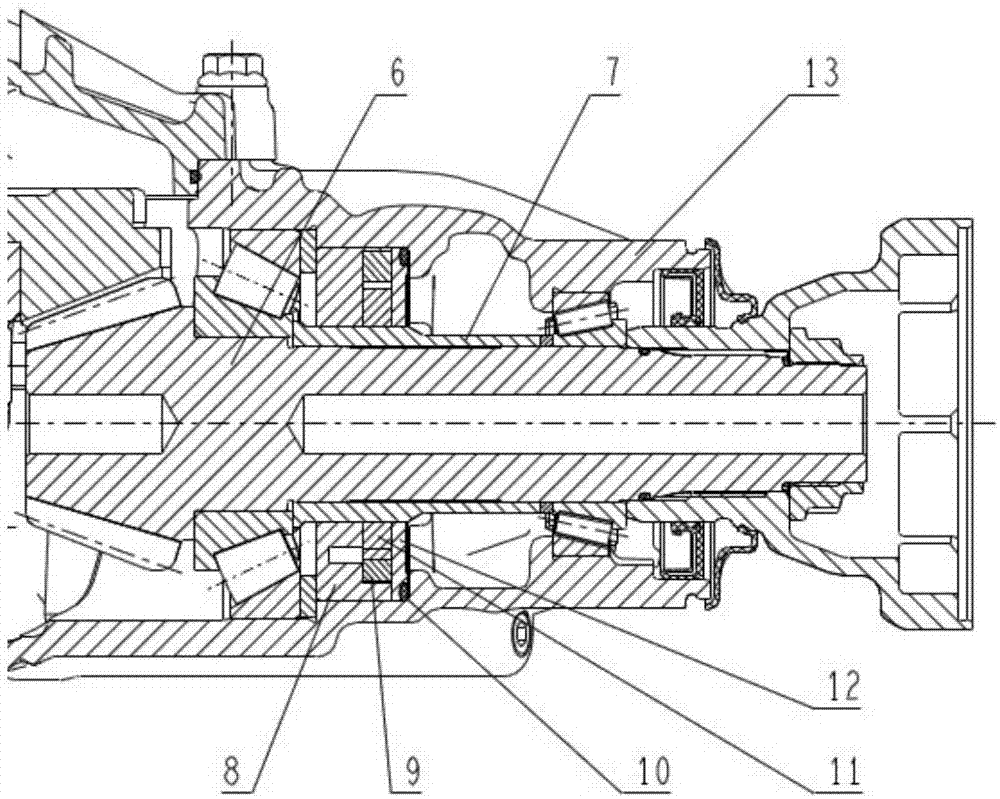

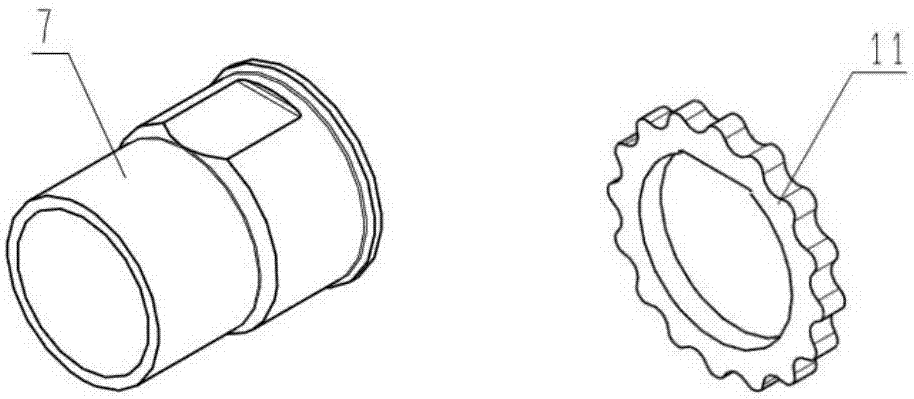

[0016] Such as figure 1 , 2 As shown, a cooling system for external circulation of drive axle lubricating oil is composed of drive axle assembly 1, oil outlet pipe, oil return pipe, lubricating oil cooler 3, check valve 5, unloading valve 4, drive axle assembly 1 Including the cooling oil pump 2 installed in the main reducer housing 13, the cooling oil pump 2 is integrated with the driving bevel gear 6. The power of the cooling oil pump 2 comes from the active bevel gear 6, the main reducer housing 13 has a lubricating oil channel C, the main reducer housing oil outlet hole F, and the main reducer housing oil return hole D; when the drive axle assembly 1 When working, the cooling oil pump 2 sucks the lubricating oil at the bottom of the drive axle assembly 1 through the lubricating oil passage C, and enters the lubricating oil cooler 3 through the oil outlet pipe, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com