Drought-resistant flood-prevention pipeline dredging all-in-one machine

An all-in-one machine and pipeline technology, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of easy re-blocking, time-consuming and labor-intensive problems, and achieve the effect of cleaning the inner wall of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

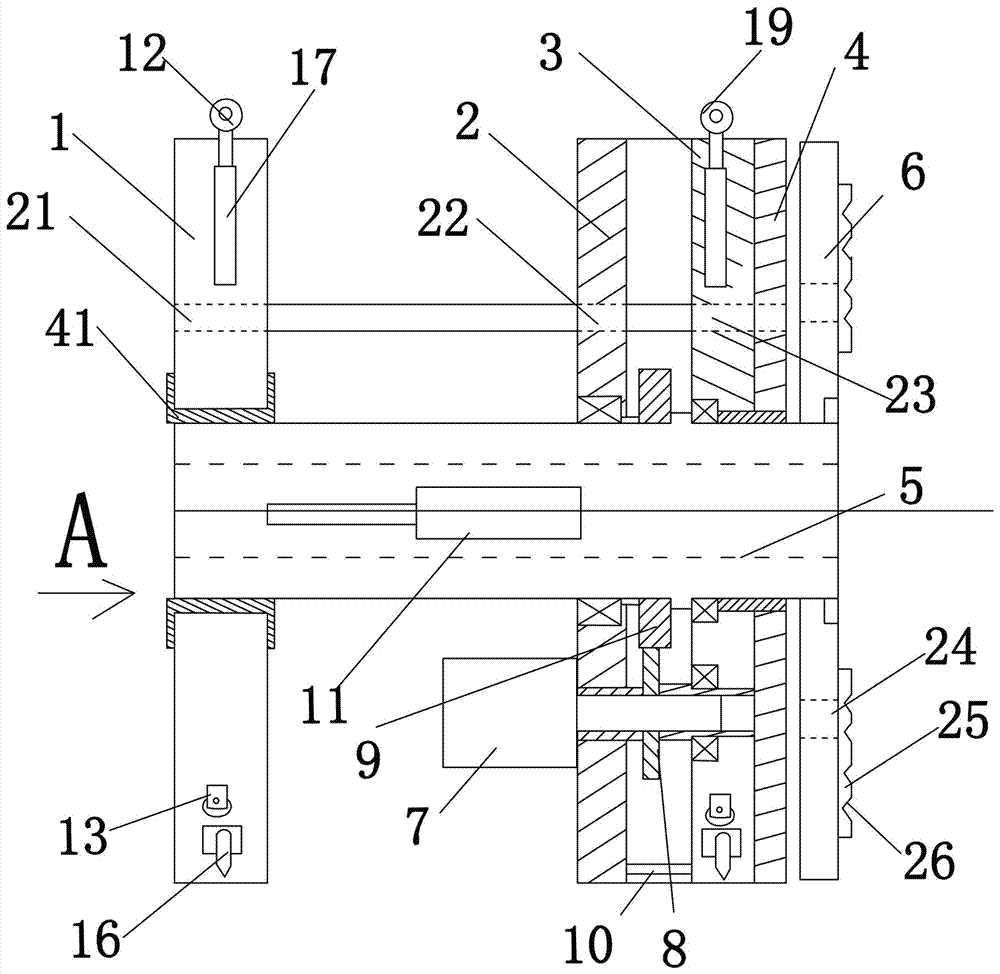

[0042] Previously described in this article as figure 1 on the right side of , followed by figure 1 in the left side.

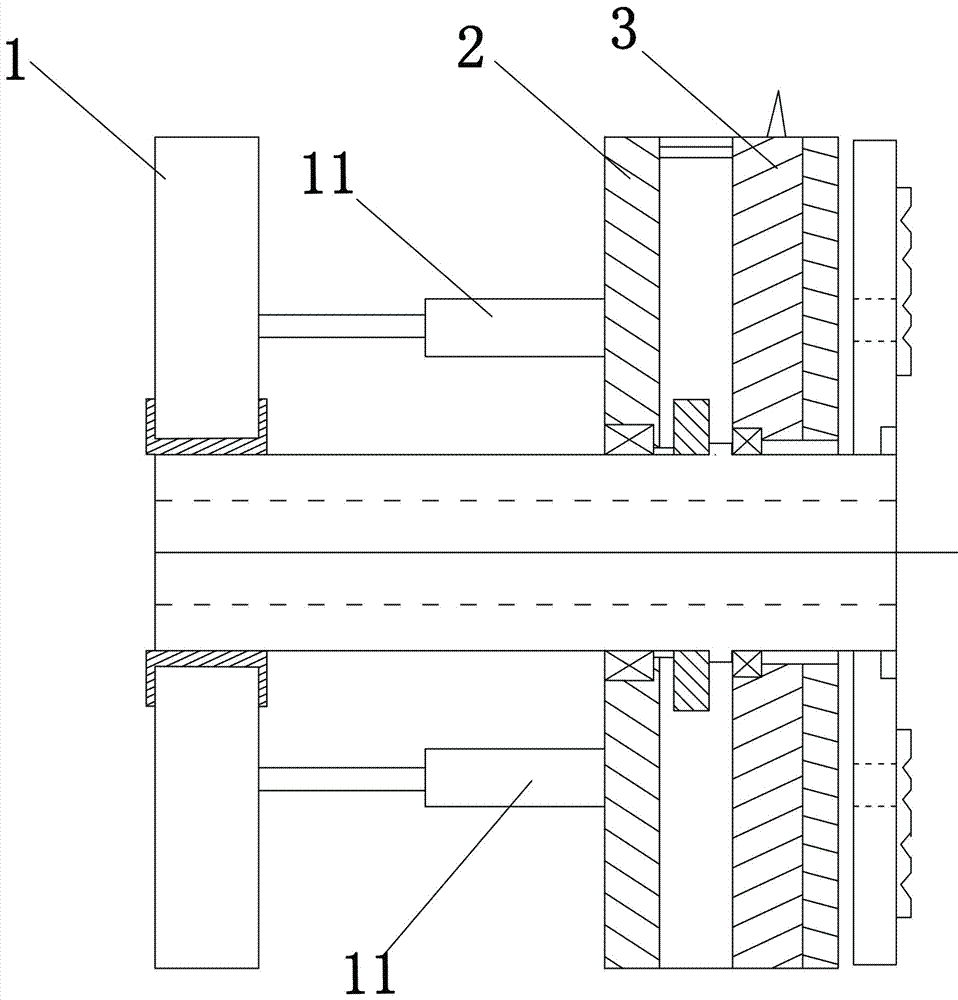

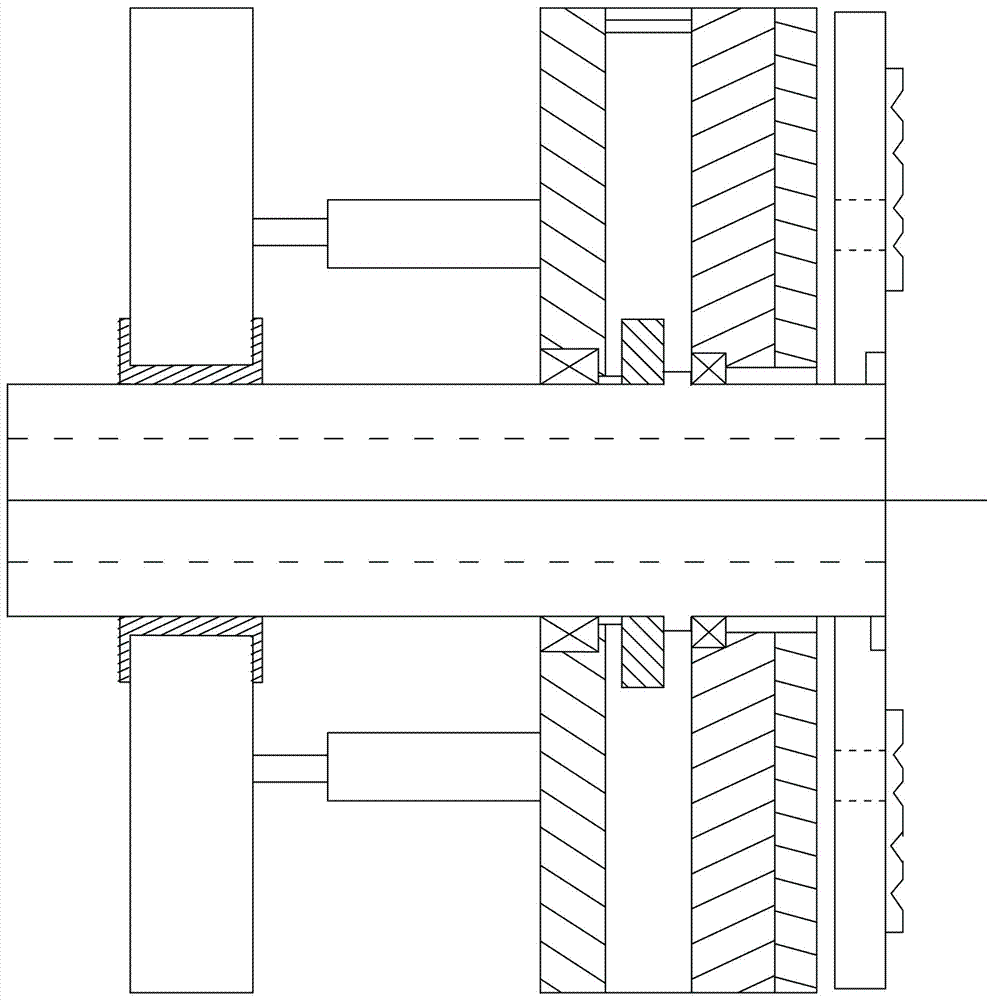

[0043] The all-in-one machine for drought and flood control pipeline dredging includes a first support plate 1 , a second support plate 2 and a third support plate 3 .

[0044] A hollow main shaft 5 with an axial through hole is perforated between the first supporting disc 1, the second supporting disc 2 and the third supporting disc 3. The hollow main shaft 5 is supported on the second supporting disc 2 through bearings, and the hollow main shaft 5 is also passed through The bearing is supported on the third support disc 3 . The first supporting disc 1 and the hollow main shaft 5 are slidingly fitted and can rotate with each other, and a sliding bearing 41 can be arranged therebetween.

[0045] A cutter head 6 is fixed on the hollow main shaft 5 in front of the third supporting disc 3 .

[0046] A hydraulic motor 7 arranged horizontally is fixed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com