Drilling hole cleaning system and cleaning method

A technology for drilling inside and on drilling rigs, which is applied in the direction of drill pipe, drill pipe, earthwork drilling and mining, etc., to achieve the effect of reducing friction, extending the direction and realizing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with embodiment.

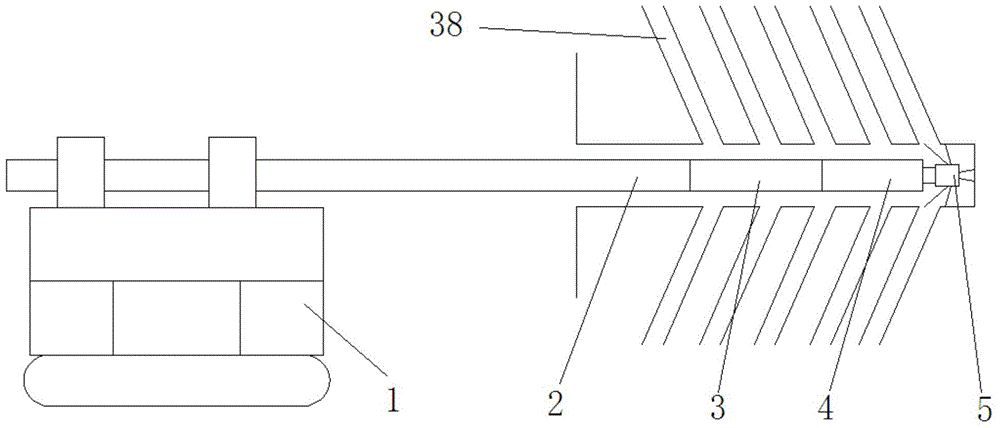

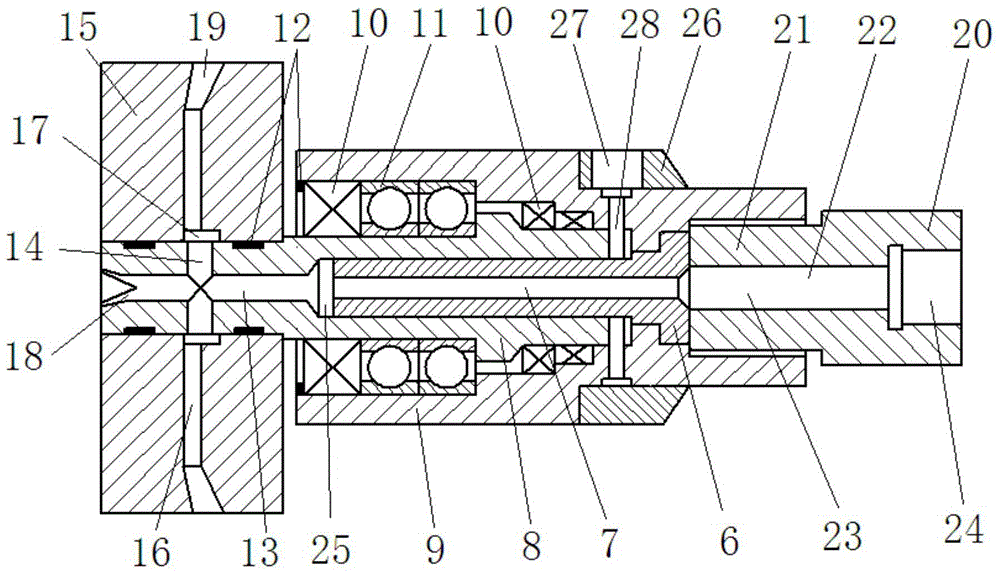

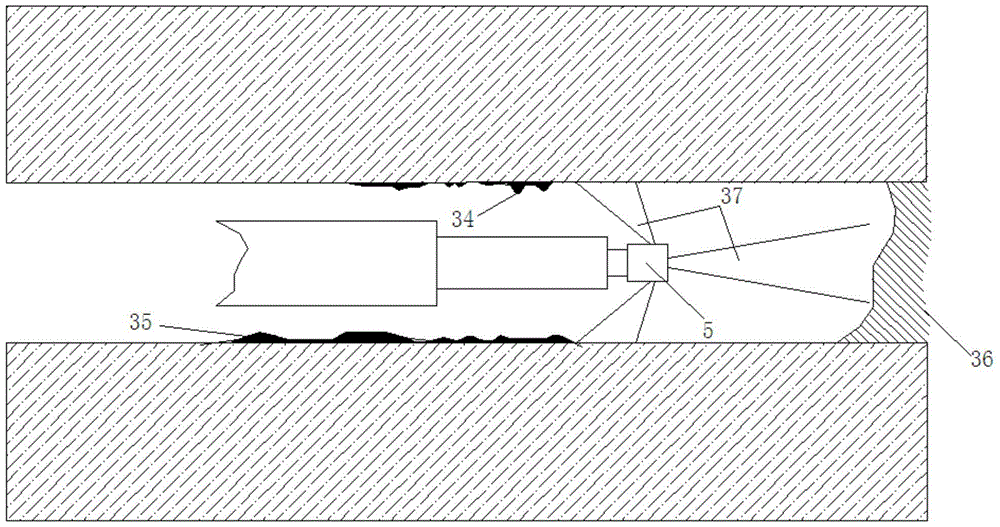

[0035] according to Figure 1 ~ Figure 2As shown, a drilling cleaning system of the present invention comprises a drilling machine 1, a drill pipe 2 is arranged on the top of the drilling machine 1, a rotary nozzle 5 is installed on the head of the drilling pipe 2, and a water pipe (not shown in the figure) is arranged on the drilling pipe 2 shown), the water pipe communicates with the rotary nozzle 5, the end of the rotary nozzle 5 is provided with a straight nozzle 18 and an oblique nozzle 19, and the drill rod 2 of the drilling rig 1 is provided with a The recording device 3 and the driving device 4 used to drive the drilling machine to move along the recorded path, the recording device 3 and the driving device 4 are externally connected to the display device through wires to display the movement track of the drilling machine 1. In this embodiment, the drilling machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com