Method of improving saline-alkali soil to plant plants by using prepared sludge nutrient substrate

A nutrient matrix and sludge technology, which is applied in the field of sludge treatment and saline-alkali land treatment, to achieve the effects of improving conversion efficiency, fermentation efficiency, and hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

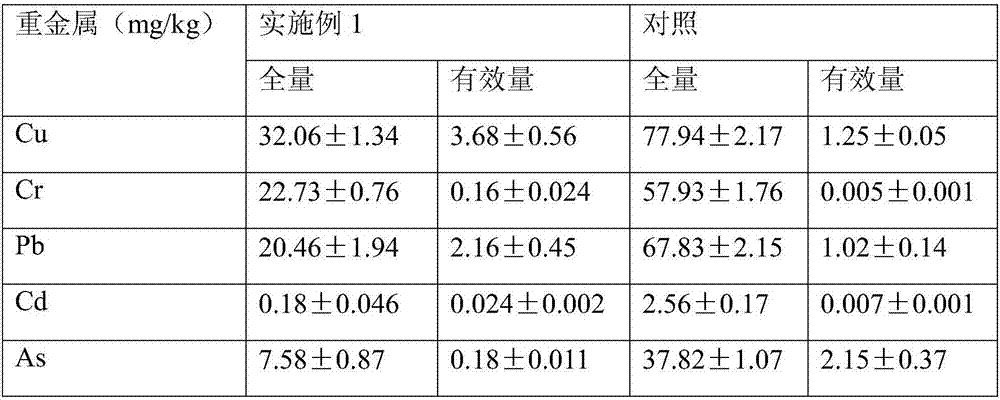

Embodiment 1

[0024] A preparation method of sludge nutrient matrix, comprising the following steps:

[0025] Take the sludge that has undergone primary treatment from the sewage treatment plant, add 2.5% sodium citrate, 11% humic acid and 1% potassium chloride to the sludge, stir well and let it stand for 1-2 hours , suction and filter the surface moisture, and then dehydrate until the moisture content is 75%-80%, to obtain pretreated sludge; place the pretreated sludge in a fermentation tank at 60°C for the first fermentation for 5 days, and obtain the first fermentation material; Mix the first fermentation material, sludge and high-temperature composting fermentation bacteria liquid at a volume ratio of 10:25:3, stir evenly, and conduct a second fermentation at 85°C for 4 days to obtain the second fermentation material; Mix the fermented material, peat and compost fermentation liquid at room temperature at a volume ratio of 15:15:2, stir evenly, and ferment for the third time at 38°C for...

Embodiment 2

[0029] A preparation method of sludge nutrient matrix, comprising the following steps:

[0030] Take the sludge that has undergone primary treatment from the sewage treatment plant, add 3.0% sodium citrate, 10% humic acid and 2% potassium chloride to the sludge, stir it evenly and let it stand for 1-2 hours , suction and filter the surface moisture, and then dehydrate until the moisture content is 75%-80%, to obtain pretreated sludge; put the pretreated sludge in a fermentation tank at 58°C for the first fermentation for 5.5 days, and obtain the first fermentation material ; mix the first fermentation material, sludge and high-temperature composting fermentation liquid in a volume ratio of 10:25:3, stir evenly, and conduct a second fermentation at 82°C for 4.5 days to obtain the second fermentation material; Mix the secondary fermentation material, peat and normal temperature composting fermentation broth at a volume ratio of 15:15:2, stir evenly, and ferment for the third tim...

Embodiment 3

[0034] A preparation method of sludge nutrient matrix, comprising the following steps:

[0035] Take the sludge that has undergone primary treatment in the sewage treatment plant, add 4.0% sodium citrate, 9% humic acid and 3% potassium chloride to the sludge, stir it evenly and let it stand for 1-2 hours , suction and filter the surface moisture, and then dehydrate until the water content is 75%-80%, to obtain pretreated sludge; place the pretreated sludge in a fermentation tank at 55°C for the first fermentation for 6 days, and obtain the first fermentation material; Mix the first fermentation material, sludge, and high-temperature composting fermentation bacteria liquid at a volume ratio of 10:25:3, stir evenly, and conduct a second fermentation at 80°C for 5 days to obtain the second fermentation material; Mix the fermented material, peat and compost fermentation liquid at room temperature at a volume ratio of 15:15:2, stir evenly, and ferment for the third time at 35°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com