Method for preparing porous and spherical basic magnesium carbonate crystal by utilizing magnesite

A magnesite and magnesium carbonate technology, applied in the direction of magnesium carbonate, can solve the problems of waste of resources and reduction of high-quality mineral resources, and achieve the effects of reducing preparation cost, reducing probability of occurrence and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

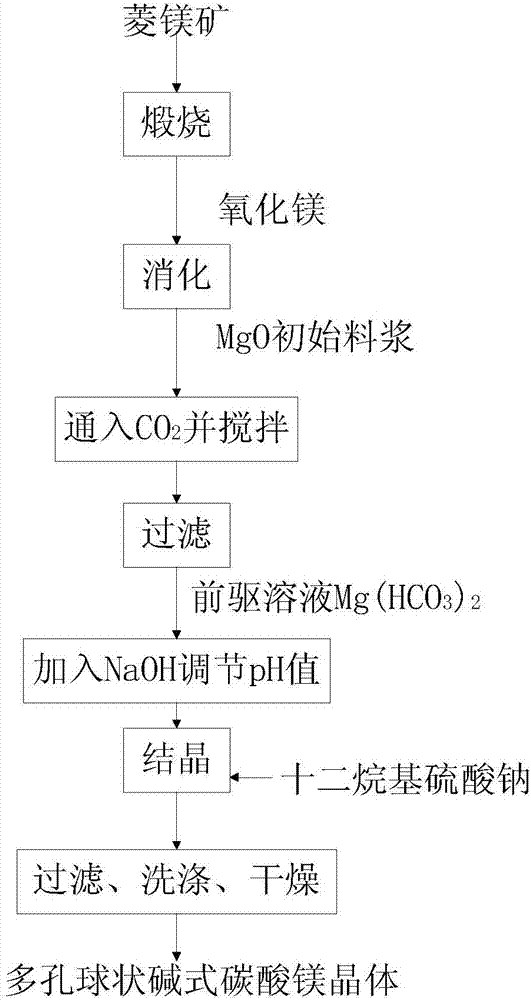

[0053] A kind of method that utilizes magnesite to prepare porous spherical basic magnesium carbonate crystal, its process flow diagram is shown in figure 1 , including the following steps:

[0054] (1) Calcined magnesite

[0055] The magnesite was calcined at 750°C for 3.0 hours, so that the decomposition rate of magnesite reached 99%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 30s;

[0056] Grinding the activated magnesium oxide to -74 μm to obtain activated magnesium oxide powder;

[0057] (2) Digest and prepare Mg(OH) 2 suspension

[0058] Using the obtained activated magnesia powder as raw material, add deionized water at 90°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:40;

[0059] Put the initial slurry of MgO in a constant temperature water bath at 60°C, stir for 3.5 hours, and air-cool to room tempera...

Embodiment 2

[0069] A method utilizing magnesite to prepare porous spherical magnesium basic carbonate crystals, comprising the steps of:

[0070] (1) Calcined magnesite

[0071] The magnesite was calcined at 700°C for 3.0 hours, so that the decomposition rate of magnesite was 98%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 28s;

[0072] The activated magnesium oxide is pulverized into activated magnesium oxide powder with a particle size of -72 μm;

[0073] (2) Digest and prepare Mg(OH) 2 suspension

[0074] Using the obtained activated magnesia powder as raw material, add deionized water at 70°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:50;

[0075] Put the initial MgO slurry in a constant temperature water bath at 55°C, stir for 5.0 h, and air cool to room temperature to obtain Mg(OH) 2 suspension;

[0076] (3) Prepara...

Embodiment 3

[0083] A method utilizing magnesite to prepare porous spherical magnesium basic carbonate crystals, comprising the steps of:

[0084] (1) Calcined magnesite

[0085] The magnesite was calcined at 800°C for 1.0h, so that the decomposition rate of magnesite was 99%, and active magnesium oxide was obtained. The activity was detected by the citric acid method, and the discoloration time was 30s;

[0086] Grinding activated magnesium oxide to activated magnesium oxide powder with a particle size of -70 μm;

[0087] (2) Digest and prepare Mg(OH) 2 suspension

[0088] Using the obtained activated magnesia powder as raw material, add deionized water at 100°C, fully stir to prepare MgO initial slurry; wherein, according to the mass ratio, activated magnesia powder: deionized water = 1:12;

[0089] Put the initial MgO slurry in a constant temperature water bath at 65°C, stir for 1.0 h, and air cool to room temperature to obtain Mg(OH) 2 suspension;

[0090] (3) Preparation of precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com