A kind of rapid solidification water-soluble sand casting method

A sand casting, water-soluble technology, used in casting molding equipment, cores, molds, etc., can solve problems such as increasing the cost of sand casting, and achieve the effect of eliminating air thermal insulation, achieving rapid solidification, and good density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

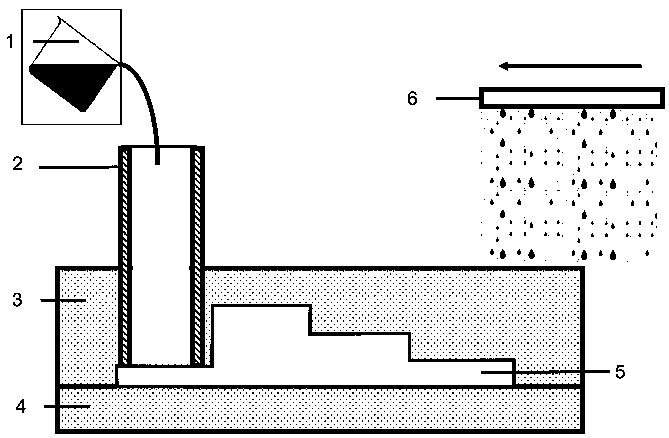

[0021] A rapid solidification water-soluble sand casting method, the specific steps are as follows:

[0022] 1. Mix silica sand, sodium silicate, magnesium sulfate, and fly ash at a mass ratio of 1:0.025:0.005:0.005 to prepare sand molds and sand cores;

[0023] 2. It is cured by self-hardening method;

[0024] 3. Group type, group core, place ceramic tube sprue cup;

[0025] 3. After melting the cast aluminum alloy ZL114A, transfer it to the ladle and pour it at 700°C;

[0026] 4. Turn on the cooling water, and the erosion equipment moves from the far end of the sprue cup of the ceramic tube to the sprue cup of the ceramic tube at a speed of 2mm / s, so that the sand mold collapses and the rapid solidification of the casting is realized;

[0027] 5. Take out the casting;

[0028] 6. Collect the broken molding sand and dry it for reuse.

Embodiment 2

[0030] A rapid solidification water-soluble sand casting method, the specific steps are as follows:

[0031] 1. Mix silica sand, sodium silicate, magnesium sulfate, and fly ash at a mass ratio of 1:0.030:0.010:0.010 to prepare sand molds and sand cores;

[0032] 2. It is cured by self-hardening method;

[0033] 3. Group type, group core, place ceramic tube sprue cup;

[0034] 3. After smelting the deformed aluminum alloy 7075, transfer it to the ladle and pour it at 710°C;

[0035] 4. Turn on the cooling water, and the erosion equipment moves from the far end of the sprue cup of the ceramic tube to the sprue cup of the ceramic tube at a speed of 8mm / s, so that the sand mold collapses and the rapid solidification of the casting is realized;

[0036] 5. Take out the casting;

[0037] 6. Collect the broken molding sand and dry it for reuse.

Embodiment 3

[0039] A rapid solidification water-soluble sand casting method, the specific steps are as follows:

[0040] 1. Mix silica sand, sodium silicate, magnesium sulfate, and fly ash at a mass ratio of 1:0.035:0.015:0.015 to prepare sand molds and sand cores;

[0041] 2. It is cured by self-hardening method;

[0042] 3. Group type, group core, place ceramic tube sprue cup;

[0043] 3. After the magnesium alloy AZ91D is melted, it is transferred to the ladle and poured at 700°C;

[0044] 4. Turn on the cooling water, and the erosion equipment moves from the far end of the sprue cup of the ceramic tube to the sprue cup of the ceramic tube at a speed of 10mm / s, so that the sand mold collapses and the rapid solidification of the casting is realized;

[0045] 5. Take out the casting;

[0046] 6. Collect the broken molding sand and dry it for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com