Flange casting box filler capable of replacing sand and preparation method thereof

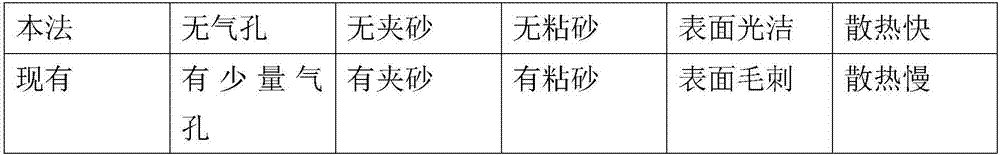

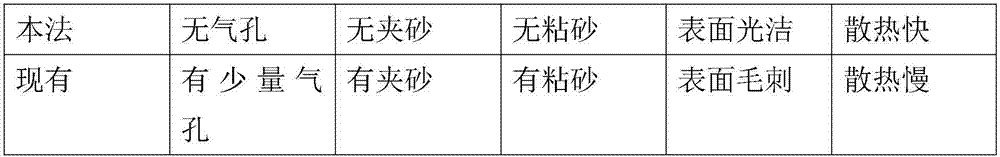

A filling and flange technology, which is applied in the field of flange casting box filling and its preparation instead of sand, can solve the problems of unfavorable transportation and storage of liquid, unfavorable health and work, and pungent odor, etc., and achieve improvement Smooth finish, reduced sensitivity, short drying time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of filling of flange casting box replacing sand,

[0031] Prepared with the following components:

[0032] 100 parts of purple sand ore, 180 parts of modified starch, 80 parts of metal slurry waste, 150 parts of deionized water, 1 part of emulsifier, 3 parts of acrylic acid, 2 parts of methacrylic acid, 3 parts of chain transfer agent, and 1 part of initiator , 10 parts of acidic or alkaline aqueous solution, 100 parts of metal particles.

[0033] A method for preparing flange casting box fillers instead of sand, comprising the following preparation methods:

[0034] Manually select the purple sand mineral material scattered in the tender mud layer, the diameter of the mineral material particle size is controlled below 3cm, and the waste soil, stone inclusions, and rust impurities in the purple sand mineral material are removed to obtain a relatively pure purple sand mineral material; the tourmaline Unwrap the rough stone to get tourmaline ore;

...

Embodiment 2

[0052] Embodiment 2: A kind of filling of flange casting box replacing sand,

[0053] Prepared with the following components:

[0054] 200 parts of purple sand ore, 220 parts of modified starch, 120 parts of metal slurry waste, 160 parts of deionized water, 2 parts of emulsifier, 14 parts of acrylic acid, 3 parts of methacrylic acid, 5 parts of chain transfer agent, 3 parts of initiator , 15 parts of acidic or alkaline aqueous solution, 120 parts of metal particles.

[0055] A method for preparing flange casting box fillers instead of sand, comprising the following preparation methods:

[0056] Manually select the purple sand mineral material scattered in the tender mud layer, the diameter of the mineral material particle size is controlled below 3cm, and the waste soil, stone inclusions, and rust impurities in the purple sand mineral material are removed to obtain a relatively pure purple sand mineral material; the tourmaline Unwrap the rough stone to get tourmaline ore;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com