Autogenous mill/semi-autogenous mill discharging flow distribution device

A semi-autogenous mill and diverting device technology, which is applied in grain processing and other directions, can solve the problems of impact and wear of the ore discharge diverting device, affecting output, and large processing capacity, so as to facilitate installation and disassembly, improve screening efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

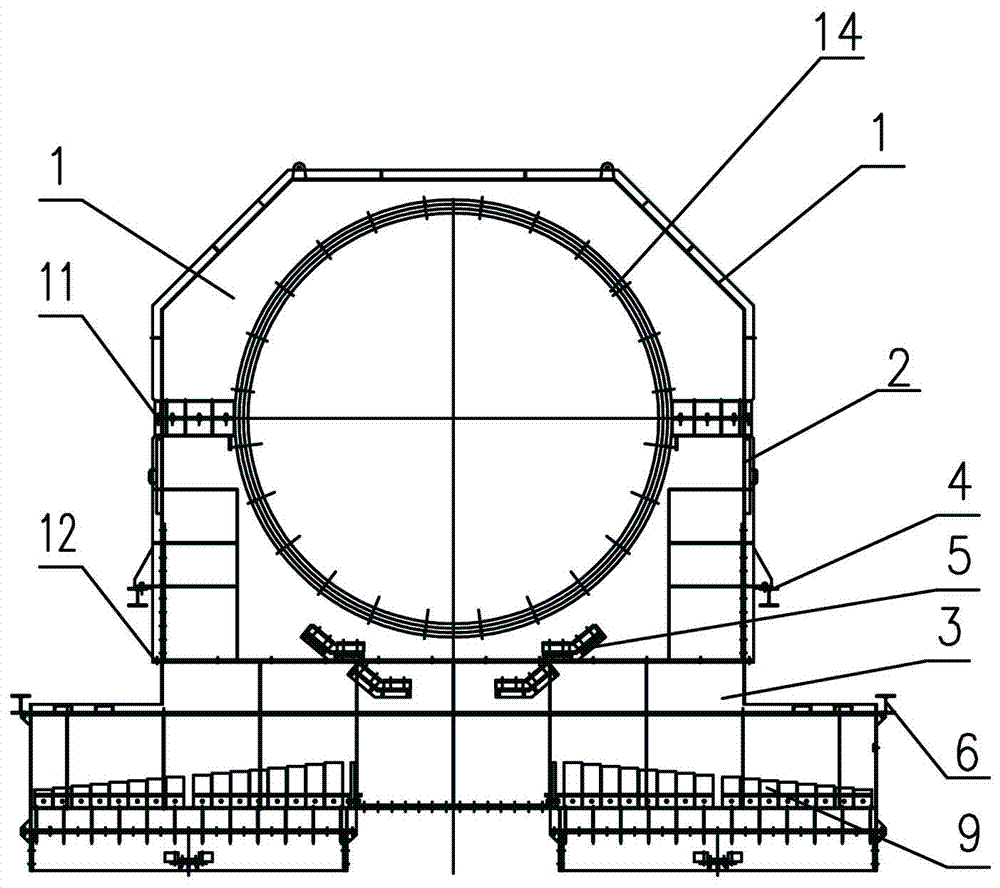

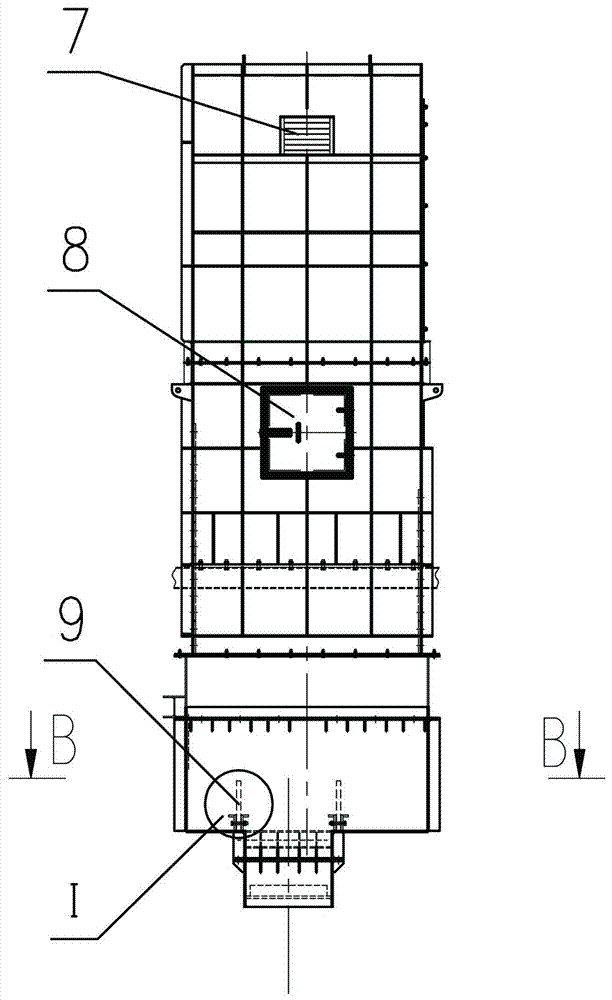

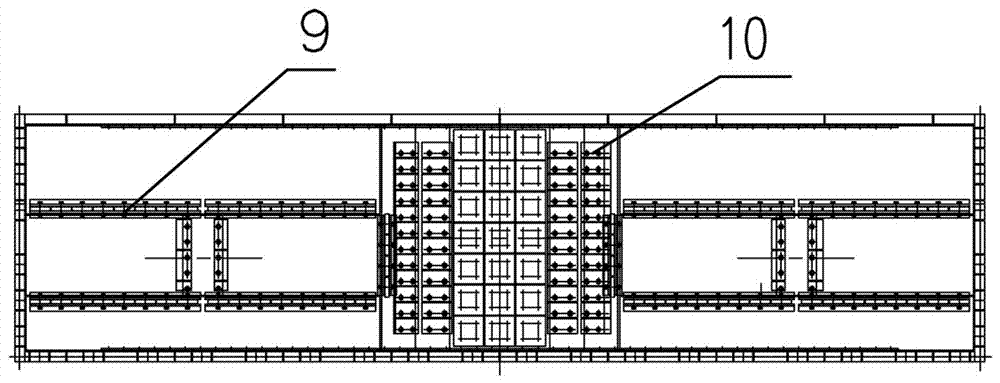

[0025] Such as Figure 1-Figure 4 As shown, a kind of autogenous mill / semi-autogenous mill discharge and diversion device of the present invention includes the autogenous mill / semi-autogenous mill discharge opening 14, and is characterized in that: it also includes an upper end cover 1, a middle collecting mechanism And the lower distribution mechanism, the design of the split structure can realize the convenience of transportation, installation and disassembly, and it is convenient to adjust the distribution plate 9 and replace the liner of the deflector 5

[0026] The middle collection mechanism includes a collection box 2 fixedly connected to the upper end cover 1 by bolts and flanges 11, and deflectors 5 fixed on both ends of the bottom of the collection box 2 by bolts. The plate 5 is located below the discharge port 14 of the autogenous mill / semi-autogenous mill and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com