Angle detection device, rotating body and motor system

An angle detection and rotation angle detection technology, applied in the field of detection, can solve the problems of the unfavorable influence of the consistency of the resolver, the inability to measure the rotation angle of the rotor normally, and the disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

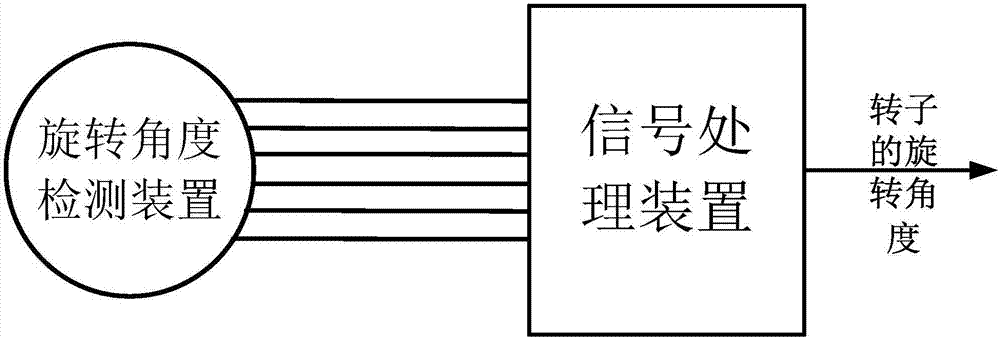

[0090] The angle detecting device includes a rotation angle detecting means and a signal processing means. The rotation angle detection device only includes a detection coil system. figure 1 Shown is a schematic diagram of the overall structure of the angle detection device.

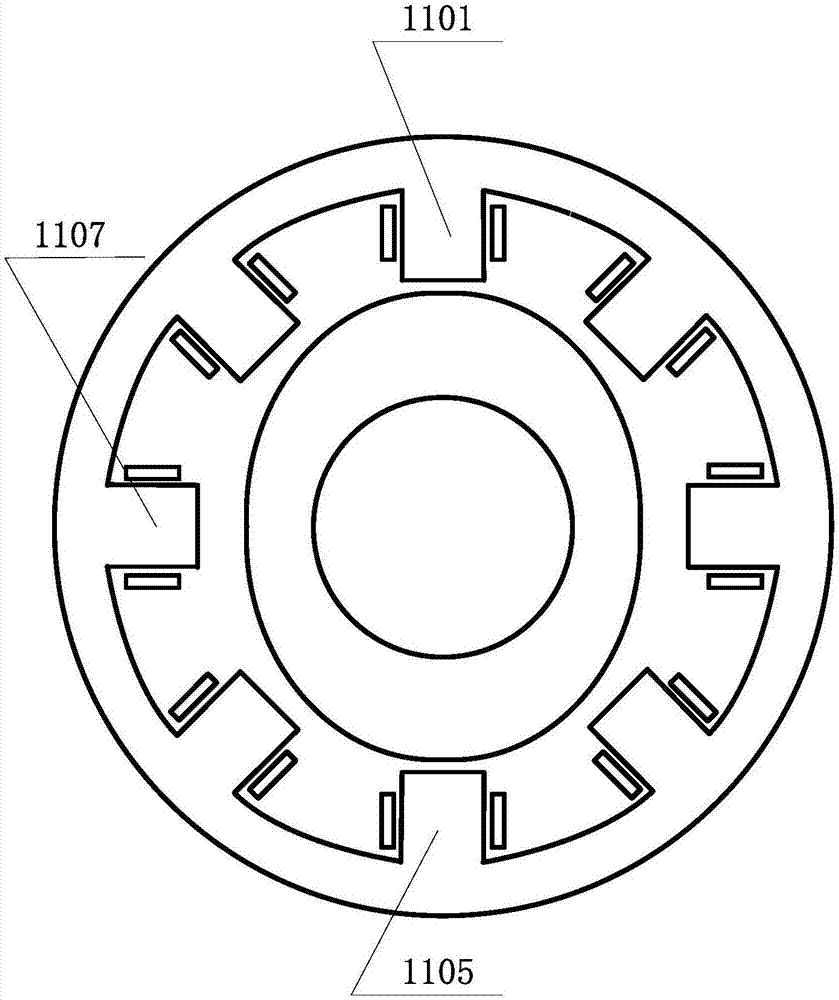

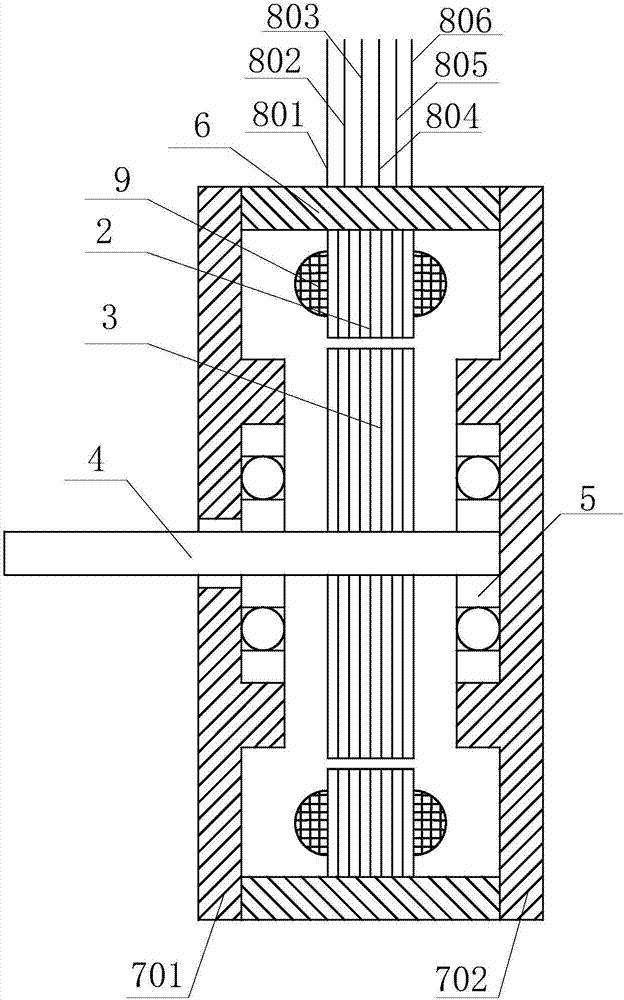

[0091] In this embodiment, the number of teeth detected by the stator of the rotation angle detection device is 8, and the number of salient poles of the rotor is 2 (set according to the number of teeth detected by the stator is 8*K, and the number of salient poles of the rotor is N; wherein, K and N are both positive integers. Therefore, in this embodiment, K is equal to 1, and N is equal to 2). figure 2 Shown is a schematic cross-sectional view of the stator and rotor of the rotation angle detection device. The stator includes a stator core, and the rotor includes a rotor core. Both the stator core and the rotor core are formed by stamping silicon steel sheets. In this embodiment, 8 stator detecti...

no. 2 example

[0121] In this embodiment, the angle detection device includes a rotation angle detection device and a signal processing device. The rotation angle detection device only includes a detection coil system. The overall structural diagram of the angle detection device can be borrowed from the first embodiment figure 1 .

[0122] In this embodiment, the number of stator detection teeth of the rotation angle detection device is 8, and the number of salient poles of the rotor is 2. In addition, in the rotation angle detection device, 8 stator decoupling teeth are provided, no coils are wound on the stator decoupling teeth, and the material of the stator decoupling teeth is magnetically permeable material. Image 6Shown is a schematic cross-sectional view of the stator and rotor of the rotation angle detection device. The stator includes a stator core, and the rotor includes a rotor core. Both the stator core and the rotor core are formed by stamping silicon steel sheets. In this...

no. 3 example

[0132] In this embodiment, the angle detection device includes a rotation angle detection device and a signal processing device. The rotation angle detection device only includes a detection coil system. The overall structural diagram of the angle detection device can be borrowed from the first embodiment figure 1 .

[0133] In this embodiment, the number of stator detection teeth of the rotation angle detection device is 8, and the number of salient poles of the rotor is 8. At the same time, a stator auxiliary tooth is provided on the two outer sides of the overall stator detection tooth (a total of 2 stator auxiliary teeth are provided). No coil is wound on the stator auxiliary tooth, and the material of the stator auxiliary tooth is a magnetic material. In addition, in this embodiment, the span of the stator yoke is less than 360 degrees. Figure 7 Shown is a schematic cross-sectional view of the stator and rotor of the rotation angle detection device. The stator includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com