Method for determining content of cut stem in cut tobacco based on thermal analysis technique

A technology of thermal analysis and thermogravimetric analyzer, which is used in measuring devices, analytical materials, instruments, etc., and can solve the problems of small sample discrimination, poor repeatability, and insufficient to measure the content of cut tobacco stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, operating process and principle of the present invention are further described:

[0023] The samples are the shredded leaves and the shredded stalks that are planned to be blended into a certain brand of domestic flue-cured tobacco cigarettes;

[0024] 1. Manually weigh a certain amount of formula shredded leaves and shredded stems, grind them into powder with a pulverizer, then transfer the above shredded leaves and shredded stems to an oven and dry them at 100°C for 2 hours. After drying, Blend the shredded leaf powder and the shredded stem powder according to the set blending ratio to obtain shredded tobacco samples with different shredded stem contents, and record the set shredded stem content values. The blending results are as follows:

[0025]

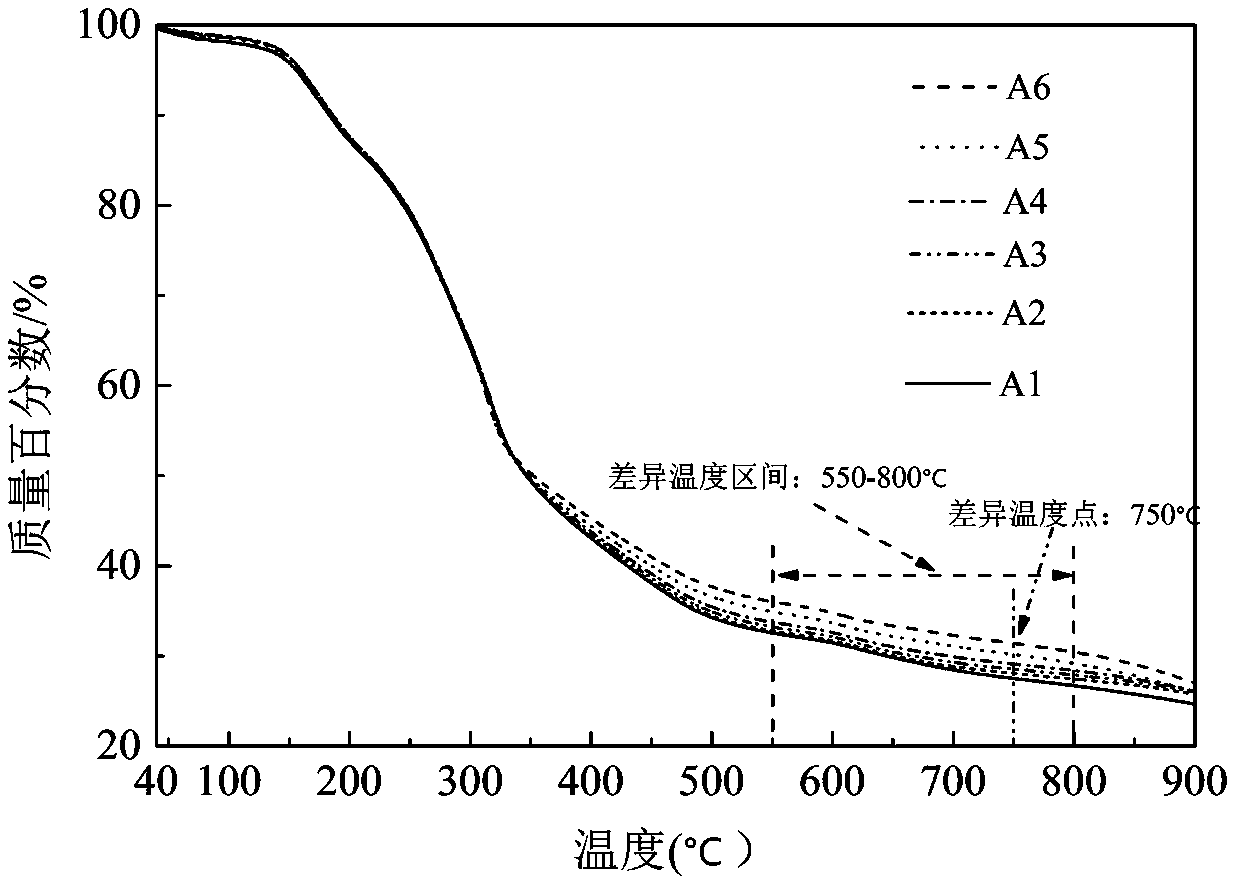

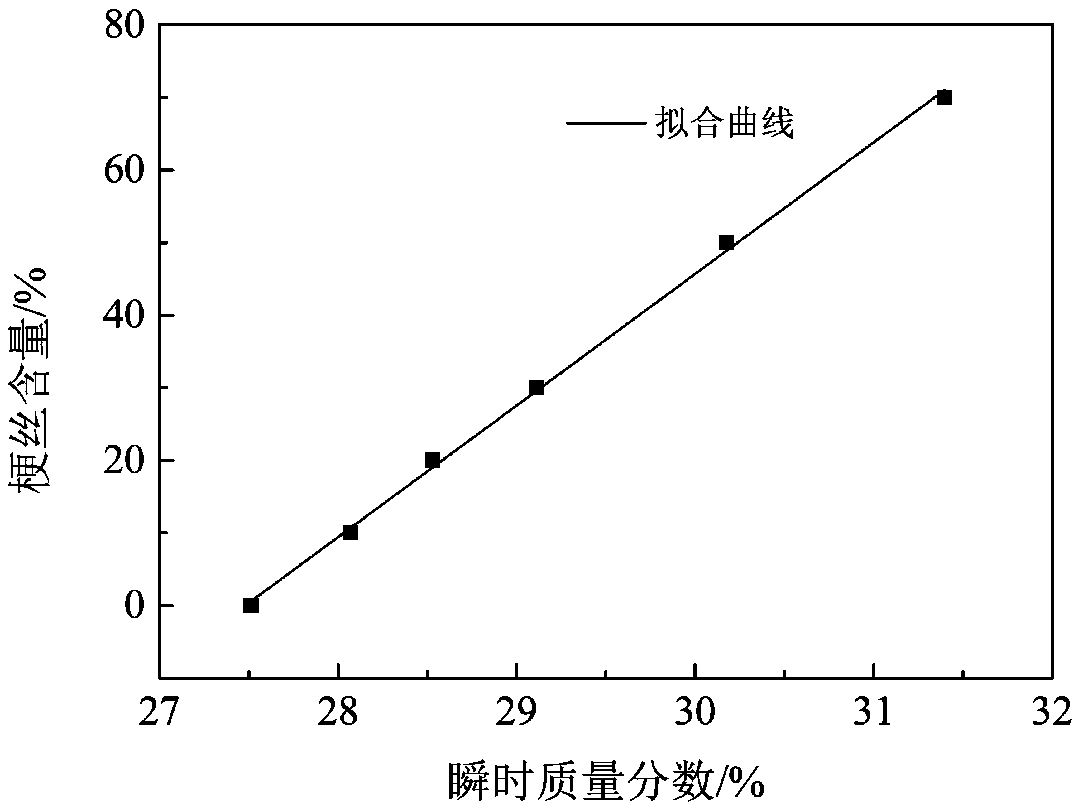

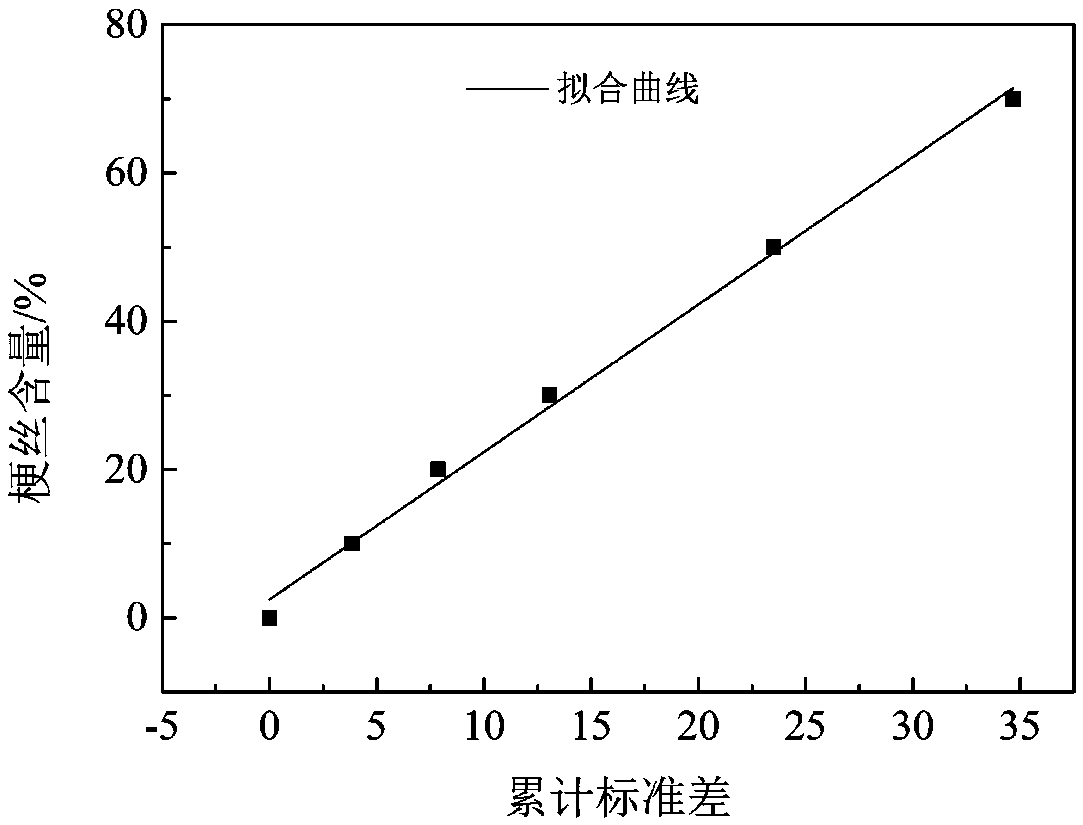

[0026] 2. Use a thermogravimetric analyzer for pyrolysis curve analysis. The purge gas is high-purity nitrogen, and the purge gas rate is 20mL / min. Each injection is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com