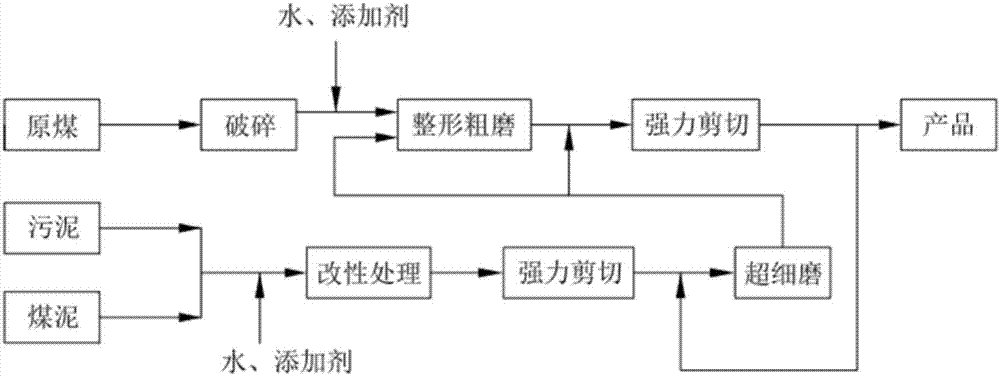

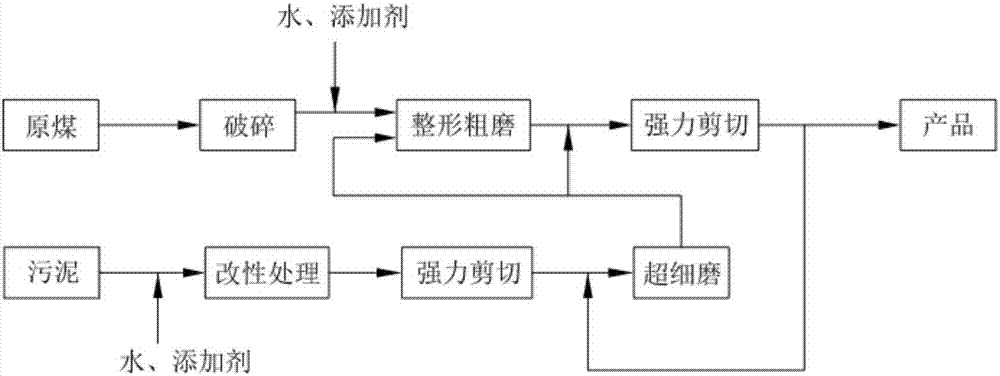

Method for preparing novel coal water slurry product from multiple materials

A technology for coal-water slurry and products, which is applied in the field of coal chemical industry, can solve the problems of poor stability, high energy consumption, uneven particle size distribution of coal-water slurry, etc., and achieves improved stability and atomization performance, optimized grading effect, and efficient cleaning. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for preparing a new type of coal-water slurry product with multiple raw materials. Among them, the raw coal is Fugu long-flame coal from Shaanxi, the sludge is municipal sludge from Shandong, and the coal slime is from a coal preparation plant in Shandong.

[0065] Among them, the water in the municipal sludge is 75wt%, containing 40ppm polyacrylamide; the coal slime full water M t 25.4wt%, analysis of water M ad 1.36wt%, Ash A ad 19.16wt%, volatile V daf 39.11wt%; long-flame coal full water M t 15.2wt%, analysis water M ad 9.14wt%, Ash A ad 15.12wt%, volatile V daf It is 36.37wt%. The maximum slurry concentration of long-flame coal in the traditional single-rod mill pulping process is 63%; the fluidity index test of coal slurry refers to the "cement slurry fluidity" in the industry standard "GB / T8077-2012 Concrete Admixture Homogeneity Test Method" of cement. "Test method, the result is 12cm; the index of the coal slurry stabil...

Embodiment 2

[0075] This embodiment provides a method for preparing a new type of coal-water slurry product with multiple raw materials. Among them, the raw coal is non-caking coal in Shenfu area, Shaanxi, and the sludge is sludge from a chemical plant in Anhui.

[0076] Among them, the water in the sludge is 90wt%, and the non-stick coal full water M t 10.6wt%, analytical water M ad 3.21wt%, Ash A ad 8.33wt%, volatile V daf It is 39.69wt%. The maximum slurry concentration of non-stick coal traditional ball mill pulping process is 65%; the fluidity index of coal slurry is 14cm; the index of coal slurry stability test is the water separation rate after standing for 8 hours, and the result is 15%.

[0077] The specific implementation method is:

[0078] (1) After the raw coal is crushed, a material A with a particle size of ≤3mm is obtained;

[0079] (2) Mix sludge with water and lignosulfonate at a ratio of 10:10:0.01. Among them, the dry basis of sludge is 1% of the dry basis of raw...

Embodiment 3

[0086] This embodiment provides a method for preparing a new type of coal-water slurry product with multiple raw materials. Among them, the raw coal is Fugu long-flame coal from Shaanxi, the sludge is municipal sludge from Shandong, and the coal slime is from a coal preparation plant in Shandong.

[0087] Among them, the water in municipal sludge is 75%wt%, and the whole water of coal slime M t 25.4wt%, analysis of water M ad 1.36wt%, Ash A ad 19.16wt%, volatile V daf 39.11wt%; long-flame coal full water M t 15.2wt%, analysis water M ad 9.14wt%, Ash A ad 15.12wt%, volatile V daf It is 36.37wt%. The maximum slurry concentration of long-flame coal in the traditional single-rod mill pulping process is 63%; the fluidity index test of coal slurry refers to the "cement slurry fluidity" in the industry standard "GB / T8077-2012 Concrete Admixture Homogeneity Test Method" of cement. "Test method, the result is 12cm; the index of the coal slurry stability test is the water separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com