A kind of preparation method of separating medium

A technology for separating media and macromolecules, applied in the field of preparation of separation media, can solve problems such as limited application of mechanical strength, and achieve good biological compatibility, excellent mechanical properties, and good cross-linking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of Porous Hydrogel Separation Medium

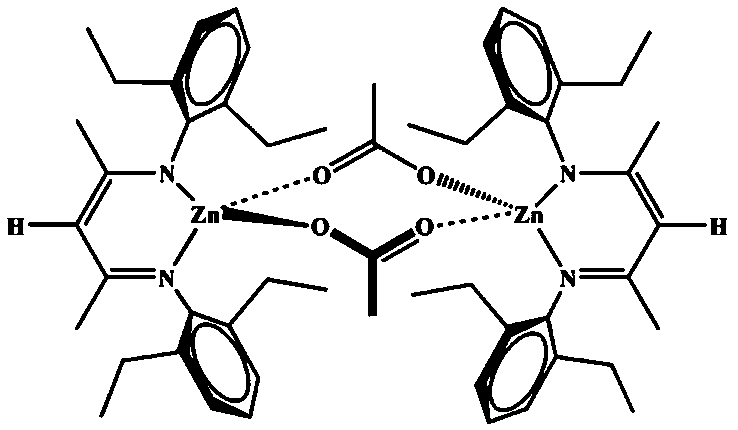

[0029] Step 1: Dissolve BSA in 10 mL ultrapure water to obtain a BSA solution with a concentration of 100 mg / mL, and add 1% cross-linking agent β-diimine zinc complex and 1,2,7, 1 mL each of 8-dioxoctane, then add 20 mg / mL NaCl 2 mL, mix well, and adjust the pH of the solution to 2.6 with dilute hydrochloric acid;

[0030] Step 2: Divide the mixed solution in Step 1 into molds, and keep at 40°C for 3 hours to prepare a hydrogel;

[0031] Step 3: Transfer the hydrogel in step 2 into a high-pressure steam sterilizer and keep it at 121°C for 20 minutes, soak and wash it in distilled water for 5 days, and change the washing water every 6 hours to remove salt and residual crosslinking agent;

[0032] Step 4: Pre-freeze the washed gel in Step 3 at -80°C for 3 h and then vacuum freeze-dry to obtain a porous hydrogel separation medium.

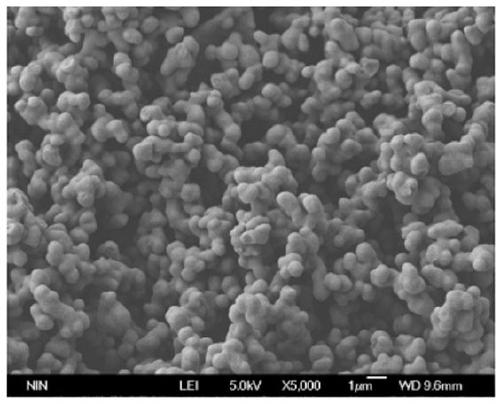

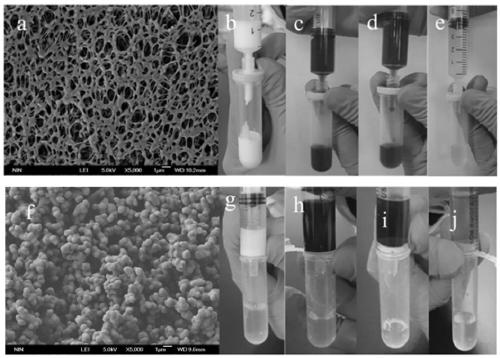

[0033] figure 2 For the SEM image of the hydrogel separation medium prepared ...

Embodiment 2

[0034] Example 2 Preparation of Porous Hydrogel Separation Medium

[0035] Step 1: Dissolve HSA in 10 mL ultrapure water to obtain a HSA solution with a concentration of 150 mg / mL, and add 1% cross-linking agent β-diimine zinc complex and 1,2,7, 1 mL each of 8-dioxoctane, then add 2 mL of 50 mg / mL KCl, mix well, and adjust the pH of the solution to 3.5 with dilute hydrochloric acid;

[0036] Step 2: Divide the mixed solution in Step 1 into molds, and keep at 50°C for 2 hours to prepare a hydrogel;

[0037] Step 3: Transfer the hydrogel in step 2 into a high-pressure steam sterilizer and keep it at 115°C for 30 minutes, soak and wash it in distilled water for 5 days, and change the washing water every 6 hours to remove salt and residual crosslinking agent;

[0038] Step 4: Pre-freeze the washed gel in Step 3 at -80°C for 3 h and then vacuum freeze-dry to obtain a porous hydrogel separation medium.

[0039] The physical and chemical properties of the porous hydrosol obtained i...

Embodiment 3

[0040] Example 3 Preparation of Porous Hydrogel Separation Medium

[0041] Step 1: Dissolve LHC in 10 mL ultrapure water to obtain an LHC solution with a concentration of 100 mg / mL, and add 2% cross-linking agent β-diimine zinc complex and 1,2,7, 1 mL each of 8-dioxoctane, then add 100 mg / mL NaNO 3 Solution 2mL, mix well, and adjust the pH of the solution to 5 with dilute hydrochloric acid;

[0042]Step 2: Divide the mixed solution in Step 1 into molds, and keep it at 60°C for 2 hours to prepare a hydrogel;

[0043] Step 3: Put the primary gel in step 2 into a high-pressure steam sterilizer and keep it at 121°C for 15 minutes, soak and wash in distilled water for 5 days, and change the washing water every 6 hours to remove salt and residual crosslinking agent;

[0044] Step 4: drying the washed gel in step 3 by supercritical carbon dioxide method to obtain a porous hydrogel separation medium.

[0045] The physical and chemical properties of the porous hydrosol obtained in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com