Compositions and methods for producing starch with novel functionality

A starch and amylopectin technology, applied in the field of corn starch, can solve problems such as low gelatinization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0144] 1. starch, containing:

[0145] an amylose content of from about 2% to about 20% by weight as measured using an amylose / amylose assay kit; and

[0146] A gelatinization temperature of the aqueous starch that is at least about 5% higher than the starch gelatinization temperature of the control starch as measured using RVA analysis,

[0147] Wherein, the starch is derived from a waxy / sugary-2 maize plant comprising at least one wxS allele in the endosperm.

[0148] 2. The starch of Embodiment 1, wherein the amylose content is from about 8% to about 15% by weight.

[0149] 3. The starch of any one of embodiments 1 or 2, wherein the water gelatinization temperature is about 5% to about 14% higher than the water gelatinization temperature of the control starch.

[0150] 4. The starch of any one of embodiments 1-3, further having a crystallization enthalpy change that is at least about 30% greater than the crystallization enthalpy change of the control starch as measure...

Embodiment 1

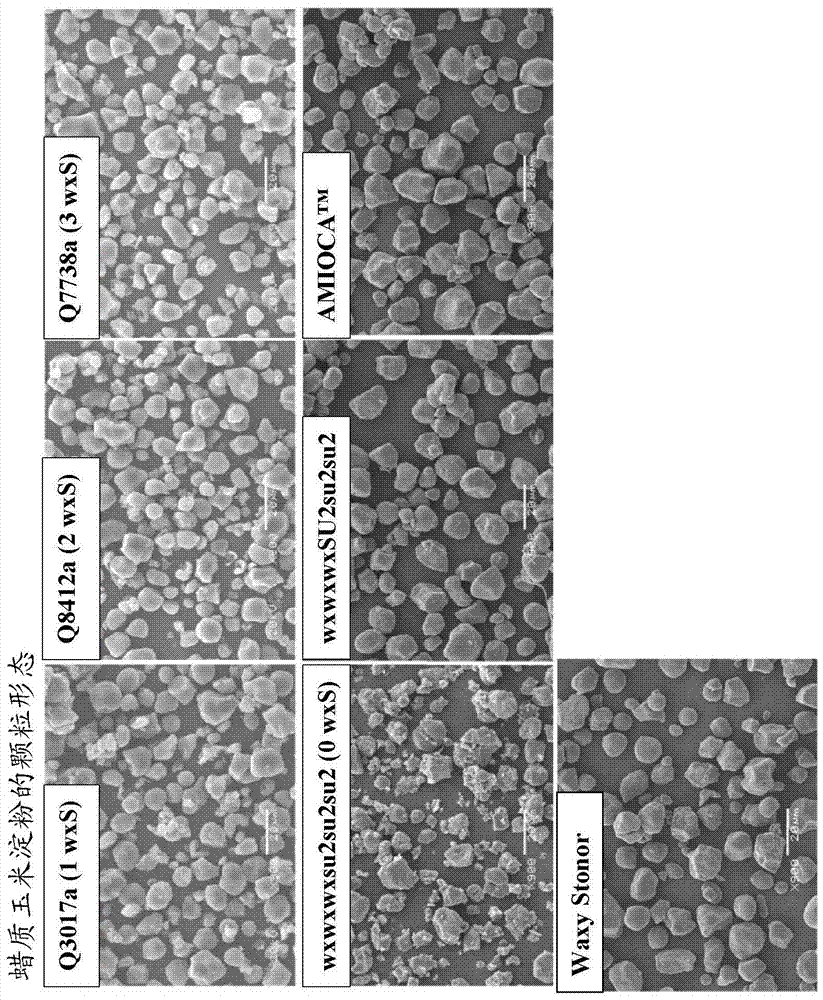

[0181] Generate grains with 1, 2 or 3 doses of the wxS allele

[0182] Due to the triploid nature of the maize endosperm, where two polar nuclei from the female parent are fertilized by one sperm cell from the male parent, three genotype combinations are possible. Use wxSwxSsu2su2 plants as females that are pollinated by wxwxsu2su2 males resulting in 'dose-2' or wxSwxSwxsu2su2su2 grains. Using wxSwxSsu2su2 as the male, whose pollination wxwxsu2su2 females resulted in "dose-1" or wxSwxwxsu2su2su2 grains. Self-pollination of wxSwxSsu2su2 results in "dose-3" or wxSwxSwxSsu2su2su2 grains.

[0183] wxS dose

Embodiment 2

[0185] Viscosity of starch using rapid viscosity gelatinizer (RVA)

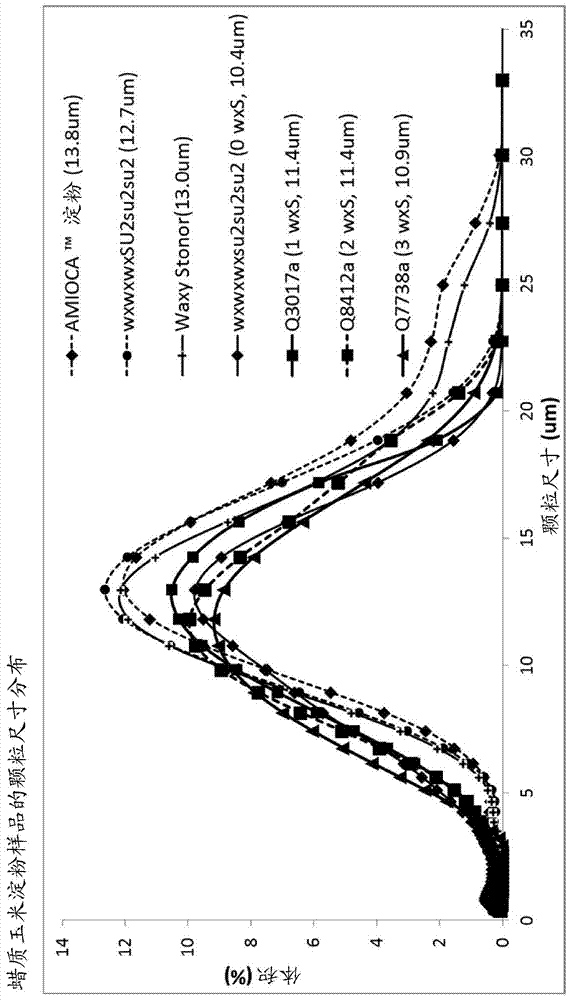

[0186] The viscosity of corn starch derived from plants containing 0, 1, 2, and 3 doses of the wxS allele in recessive sugary-2 mutant plants was determined using a Rapid Viscometer (Newport Scientific, Eden Prairie, Minn.). AMIOCA™ starch and wxwxwxSU2su2su2 starch were included as controls. The genotypes of the endosperms isolated from the starch are summarized in the table above. Amylose content was measured using the Megazyme® Amylose Kit. As the GBSSI activity increased, the amylose content of the starch increased. The amylose content of wxwxwxsu2su2su2 starch (7.4%), AMIOCA™ starch (7.1%) and wxwxwxSU2su2su2 starch (6.1%) was lower than that of Waxy Stonor (12.8%) and wxwxwxsu2su2su2 starch with 1 to 3 doses of wxS gene in the endosperm ( 8.2-14.6%). The amylose content of wxwxwxsu2su2su2 starches (7.4%, 8.2%, 13.8% and 14.6%) increased with increasing doses of wxS (0, 1, 2 and 3 doses of wxS, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com