A two-component lead-free glass powder suitable for front silver paste of crystalline silicon cells

A lead-free glass powder, crystalline silicon battery technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of small adhesion between film and substrate, narrow silver paste sintering window range, low battery conversion efficiency, etc. Achieve the effect of improving adhesion and ensuring conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

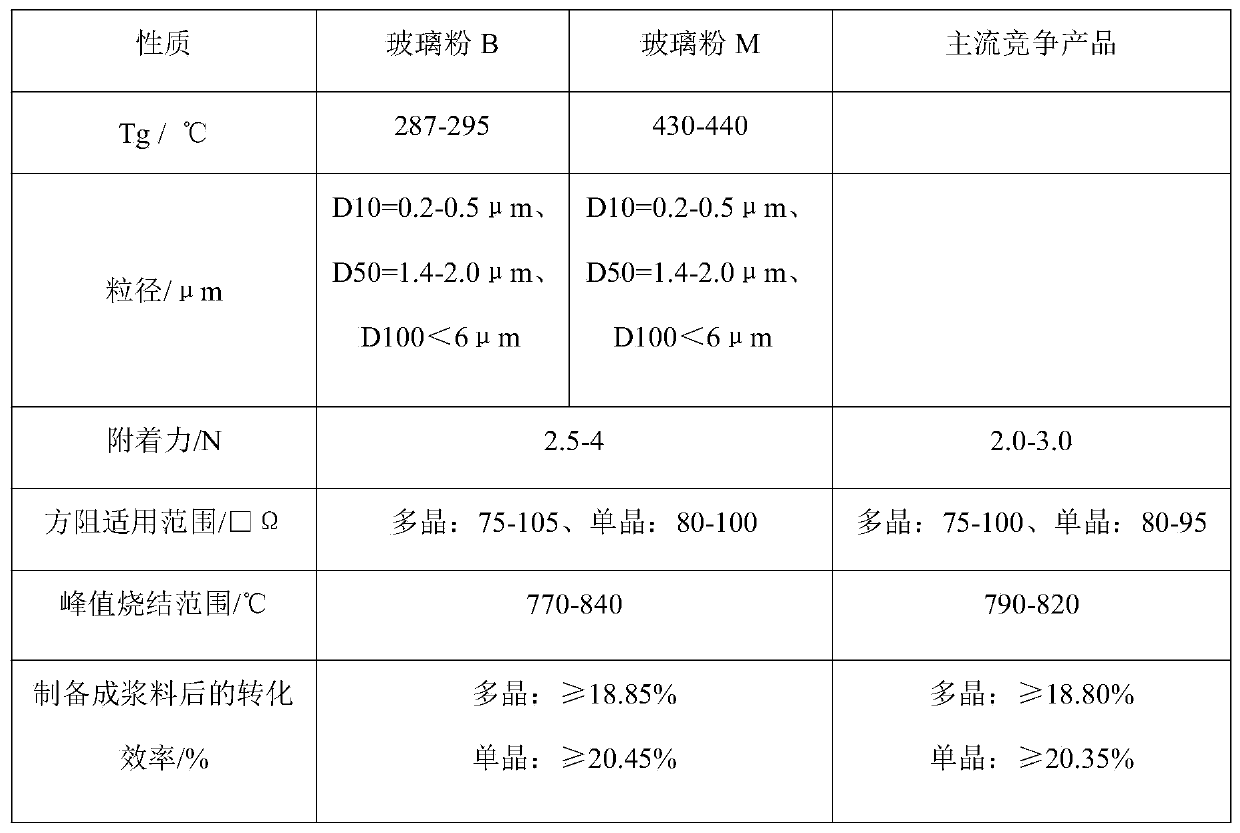

[0047] The two glass powders prepared above are uniformly mixed according to 75% glass powder B and 25% glass powder, and then the mixed two-component glass powder is mixed with 2%, silver powder 90%, and organic carrier 8% to prepare a finished slurry , According to the application process of the paste, print, sinter and test the terminal performance. The final data is shown in the following table:

[0048]

Embodiment 2

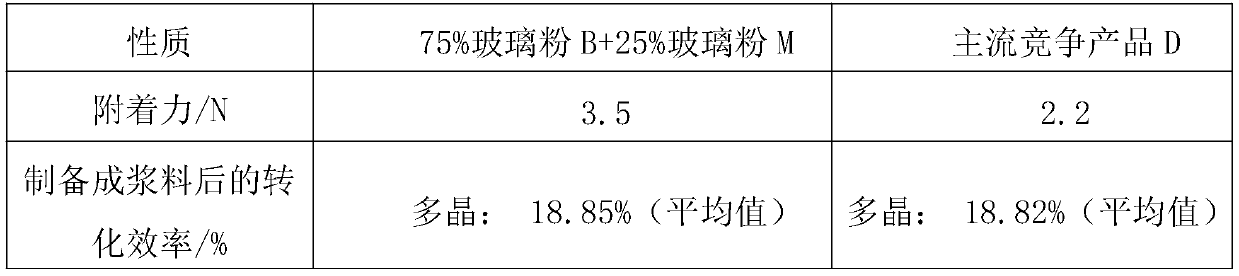

[0050] The two glass powders prepared above are uniformly mixed by 90% glass powder B and 10% glass powder, and then the mixed two-component glass powder is prepared by 2%, silver powder 90%, and organic carrier 8% to prepare a finished slurry , According to the application process of the paste, print, sinter and test the terminal performance. The final data is shown in the following table:

[0051]

Embodiment 3

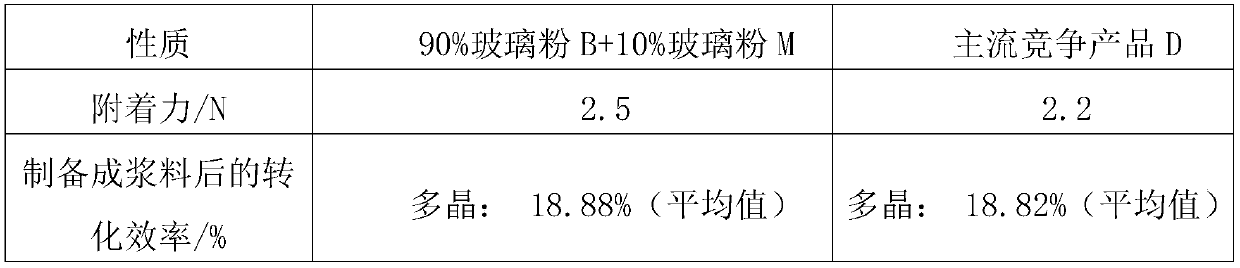

[0053] The two glass powders prepared above are uniformly mixed by 70% glass powder B and 30% glass powder, and then the mixed two-component glass powder is prepared by 2%, silver powder 90%, and organic carrier 8% to prepare a finished slurry , According to the application process of the paste, print, sinter and test the terminal performance. The final data is shown in the following table:

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com