Ultrasonic automatic welding equipment

An automatic welding and ultrasonic technology, applied in the mechanical field, can solve the problems of low work efficiency, low work efficiency, high production cost, etc., and achieve the effect of improving the degree of automation, reasonable structure design and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

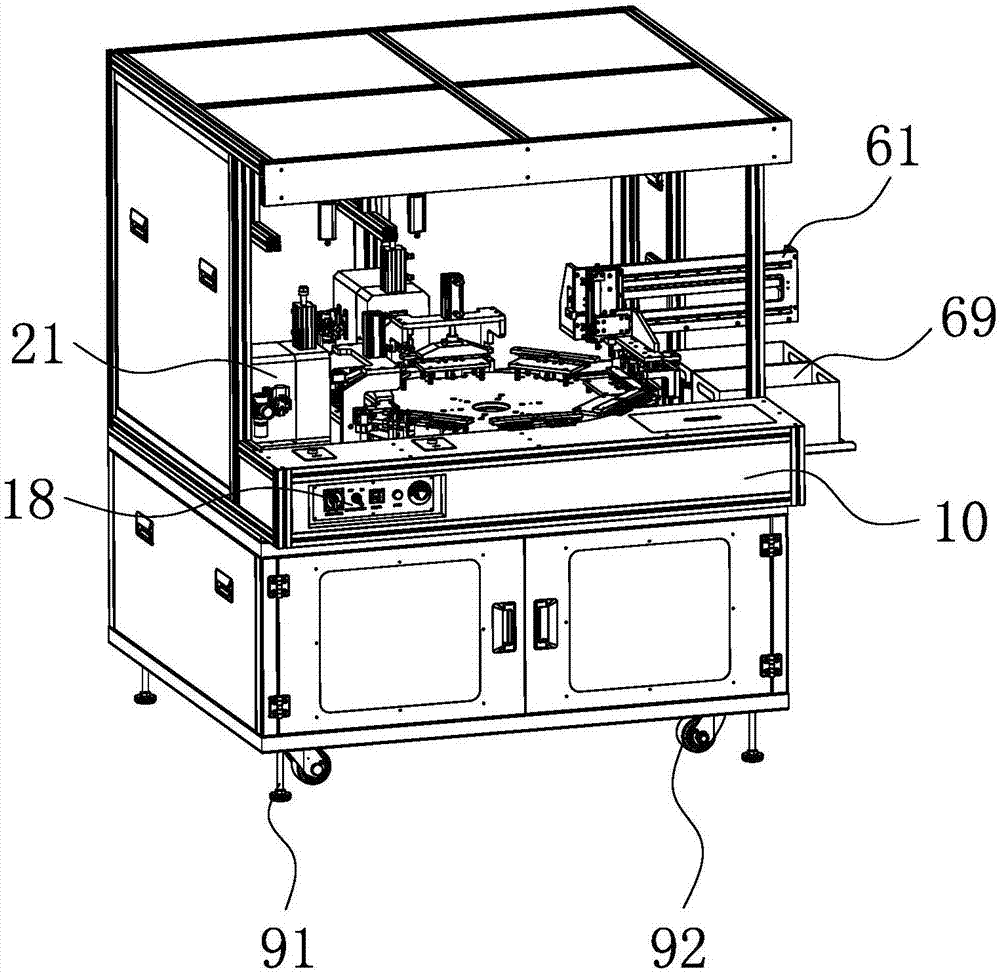

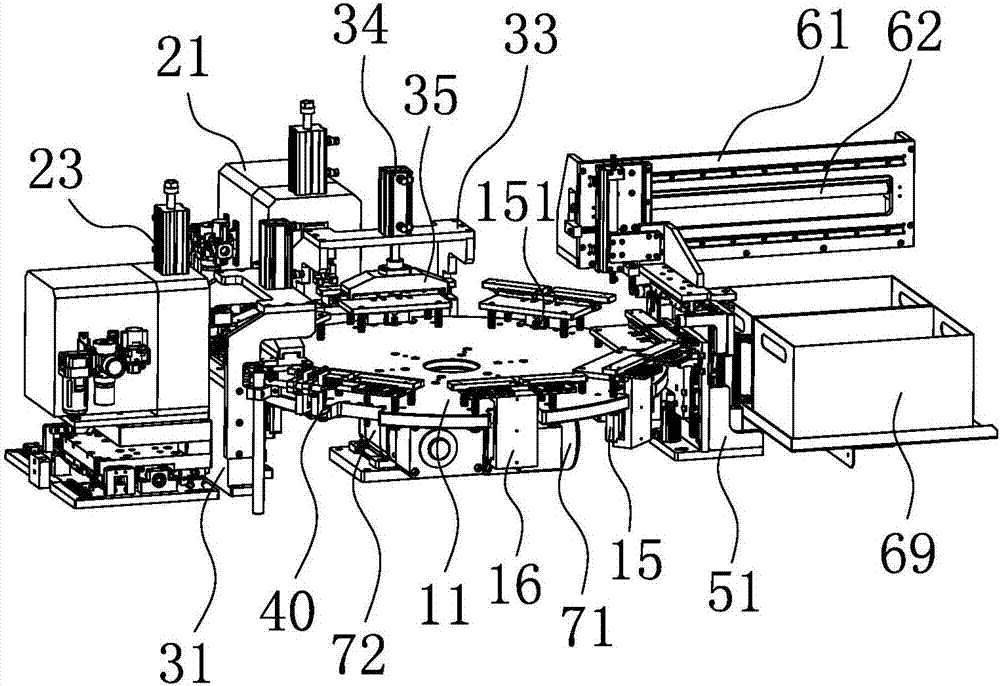

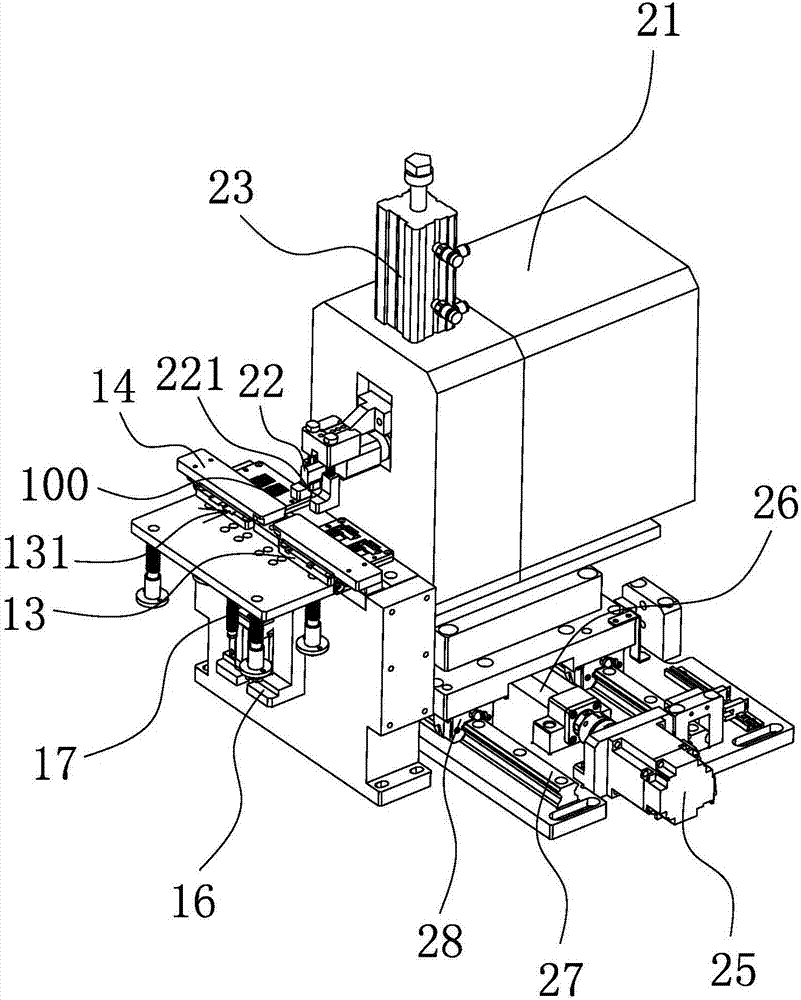

[0035] Such as figure 1 with figure 2 As shown, the ultrasonic automatic welding equipment includes:

[0036] The frame 10 has a turntable 11 arranged in a disk shape, and a plurality of stations evenly distributed are arranged on the turntable 11, and a plurality of cables 100 are clamped on each station;

[0037] There is at least one welding assembly, and an ultrasonic generator 24 is arranged in the welding assembly. When the rotary table 11 drives the cable 100 to rotate to the welding assembly, the welding assembly welds the cable 100 through ultrasonic waves;

[0038] The stripping assembly is arranged around the rotary table 11 with the welding assembly, and the stripping assembly can separate the welded cable 100 from the station;

[0039] The material taking component is set corresponding to the material stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com