Automatic stacking device of concrete blocks and stacking process thereof

A concrete block and stacking technology, which is applied in the stacking of objects, mechanical conveyors, transportation and packaging, etc., can solve the problems of low utilization rate of pallets, collapse of block stacking, etc., to facilitate maintenance and ensure stability Sexuality and ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

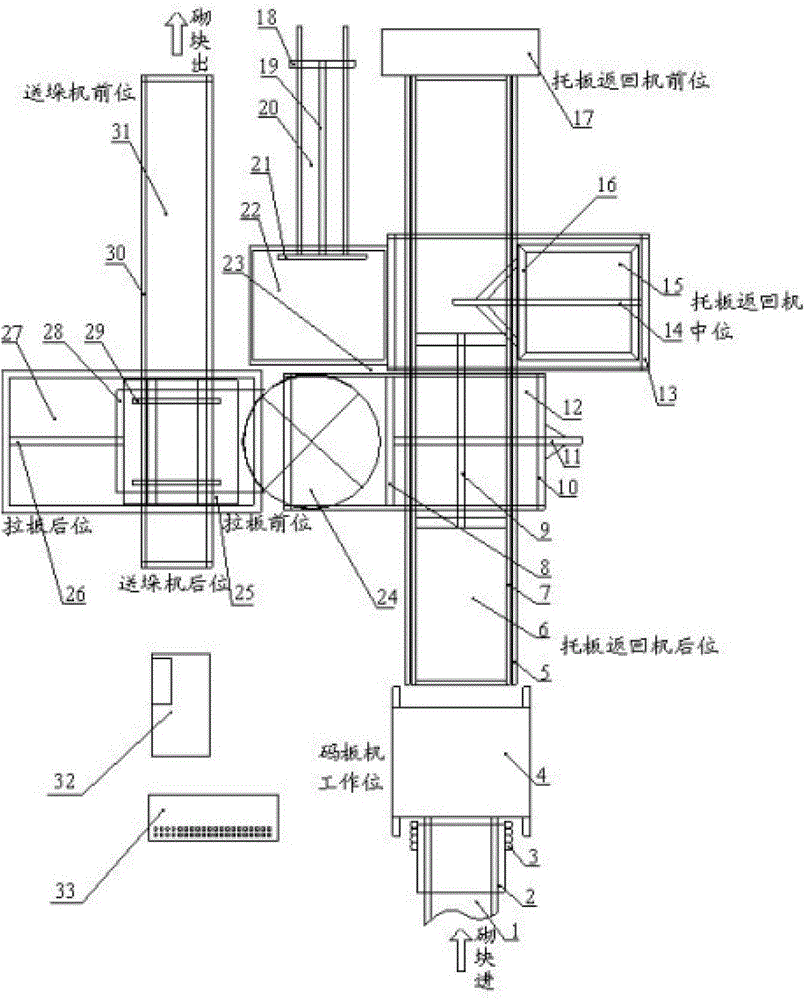

[0019] Specific embodiments of the present invention are described below with reference to the accompanying drawings.

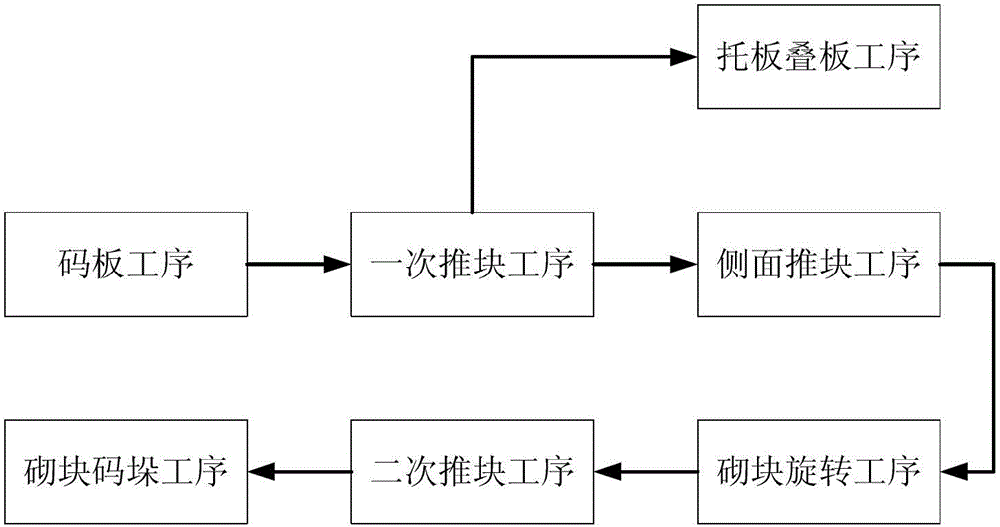

[0020] refer to figure 1 , the stacking process of the concrete block automatic stacking equipment of the present invention mainly includes the following processes: stacking plate process, primary block pushing process, side pushing block process, block rotating process, secondary block pushing process and block stacking process. It should be noted that in the following description of the palletizing process of the concrete block automatic palletizing equipment of the present invention, the working positions such as "front position", "middle position", "rear position" and "working position" can be Refer to attached figure 2 Relevant notes in . In addition, although the specific device of the present invention is described in more detail for the purpose of illustration below, the present invention is not limited thereto, but the same process can be realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com