Reshaped tricholoma matsutake chewable tablet preparation method

A technology of chewable tablets and matsutake, which is applied in the field of preparation of reshaped matsutake chewable tablets, can solve the problems of less processed matsutake products, loss of active substances, and high price of matsutake, and achieve the effects of shortening drying time, facilitating absorption, and facilitating human body absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

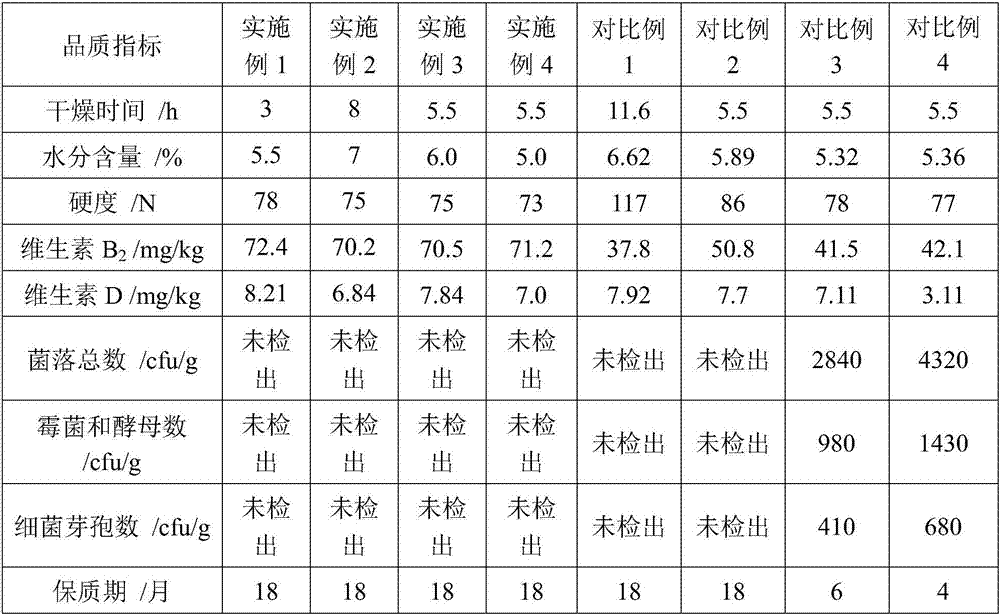

Examples

Embodiment 1

[0034] A preparation method for reshaped matsutake chewable tablets, comprising the following steps:

[0035] Step 1. Select fresh matsutake, remove deformed and rotten bacteria, wash and slice to obtain matsutake slices, and the thickness of the matsutake slices is 4mm;

[0036] Step 2, pre-drying matsutake slices in a low-temperature vacuum thin layer to obtain semi-dry slices, the moisture content of the semi-dry slices is 20% by mass, and then performing differential pressure flash drying on the semi-dry slices, and pressure differential flash drying Specifically: put the semi-dry slices in the puffing chamber, increase the pressure of the puffing chamber to 0.1MPa, raise the temperature to 90°C, stagnate for 0.5min, then drop the pressure in the puffing chamber to 0.003MPa, and drop the temperature to 50°C , stagnate for 1h to obtain a dried sheet, the mass percentage of the moisture content of the dried sheet is 5.5%;

[0037] Among them, the specific parameters of low-...

Embodiment 2

[0042] A preparation method for reshaped matsutake chewable tablets, comprising the following steps:

[0043] Step 1. Select fresh matsutake, remove deformed and rotten bacteria, wash and slice to obtain matsutake slices, and the thickness of the matsutake slices is 10mm;

[0044] Step 2. Pre-drying matsutake slices in a low-temperature vacuum thin layer to obtain semi-dry slices. The moisture content of the semi-dry slices is 30% by mass, and then the semi-dry slices are subjected to differential pressure flash drying. Specifically: put the semi-dry slices in the puffing chamber, increase the pressure of the puffing chamber to 0.6MPa, raise the temperature to 140°C, stagnate for 10 minutes, then drop the pressure in the puffing chamber to 0.01MPa, and drop the temperature to 70°C, After stagnation for 3 hours, a dried sheet was obtained, and the moisture content of the dried sheet was 7.0% by mass;

[0045] Among them, the specific parameters of low-temperature vacuum thin-l...

Embodiment 3

[0050] A preparation method for reshaped matsutake chewable tablets, comprising the following steps:

[0051] Step 1. Select fresh matsutake, remove deformed and rotten bacteria, wash and slice to obtain matsutake slices, and the thickness of the matsutake slices is 7mm;

[0052] Step 2. Pre-drying matsutake slices in a low-temperature vacuum thin layer to obtain semi-dry slices. The moisture content of the semi-dry slices is 25% by mass, and then the semi-dry slices are subjected to differential pressure flash drying. Specifically: put the semi-dry slices in the puffing chamber, increase the pressure of the puffing chamber to 0.35MPa, raise the temperature to 115°C, stagnate for 5 minutes, then drop the pressure in the puffing chamber to 0.006MPa, and drop the temperature to 60°C, After stagnation for 2 hours, a dried sheet is obtained, and the mass percentage of the moisture content of the dried sheet is less than 6.0%;

[0053] Among them, the specific parameters of low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com