A clamping and cooling device for laser quenching processing of steel plates

A technology of laser quenching and cooling device, applied in the direction of quenching device, process efficiency improvement, manufacturing tools, etc., can solve the problems of poor cooling effect, affecting quenching effect, laser power limitation, etc., to speed up the flow, improve the effect, and improve the completeness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

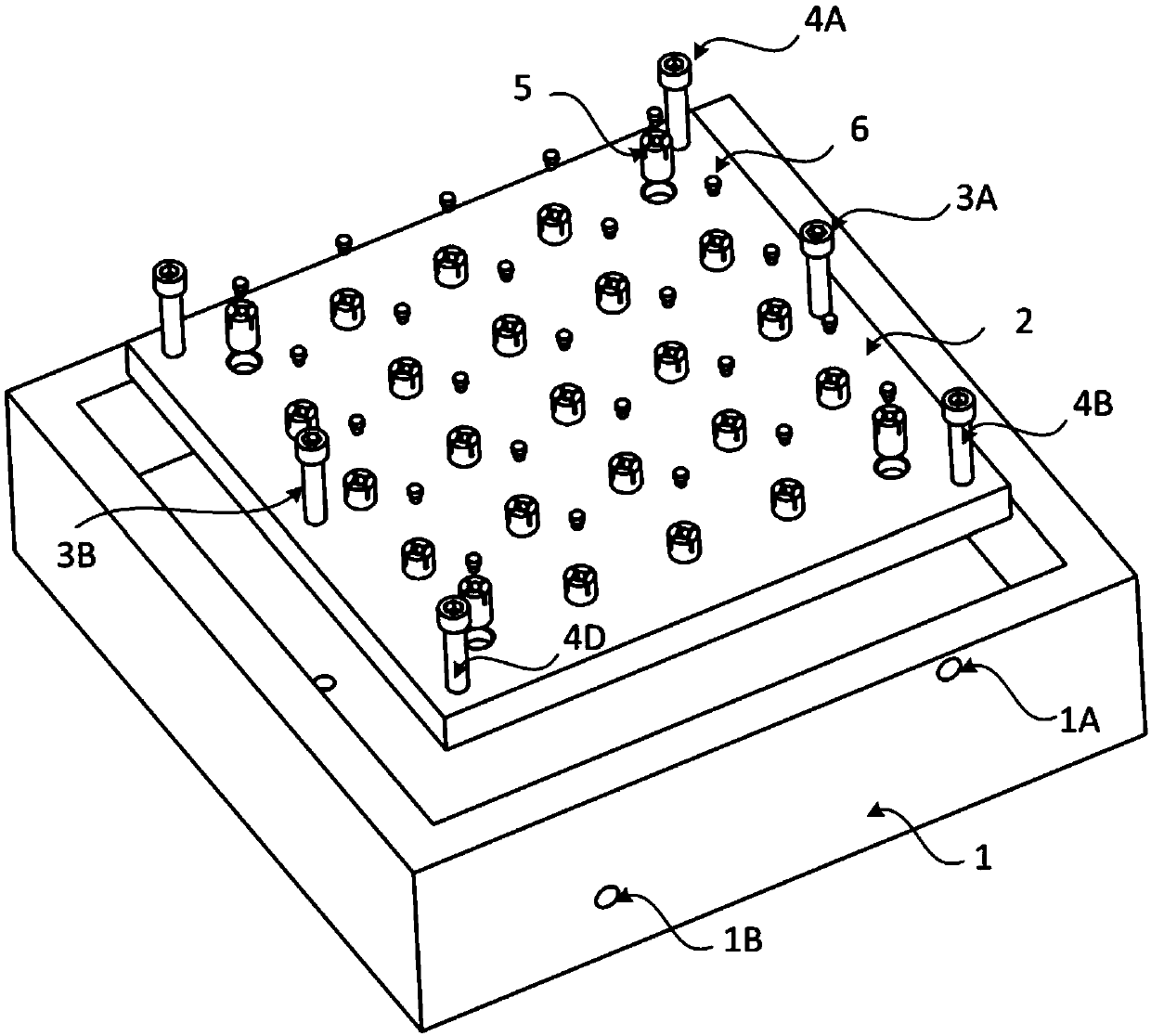

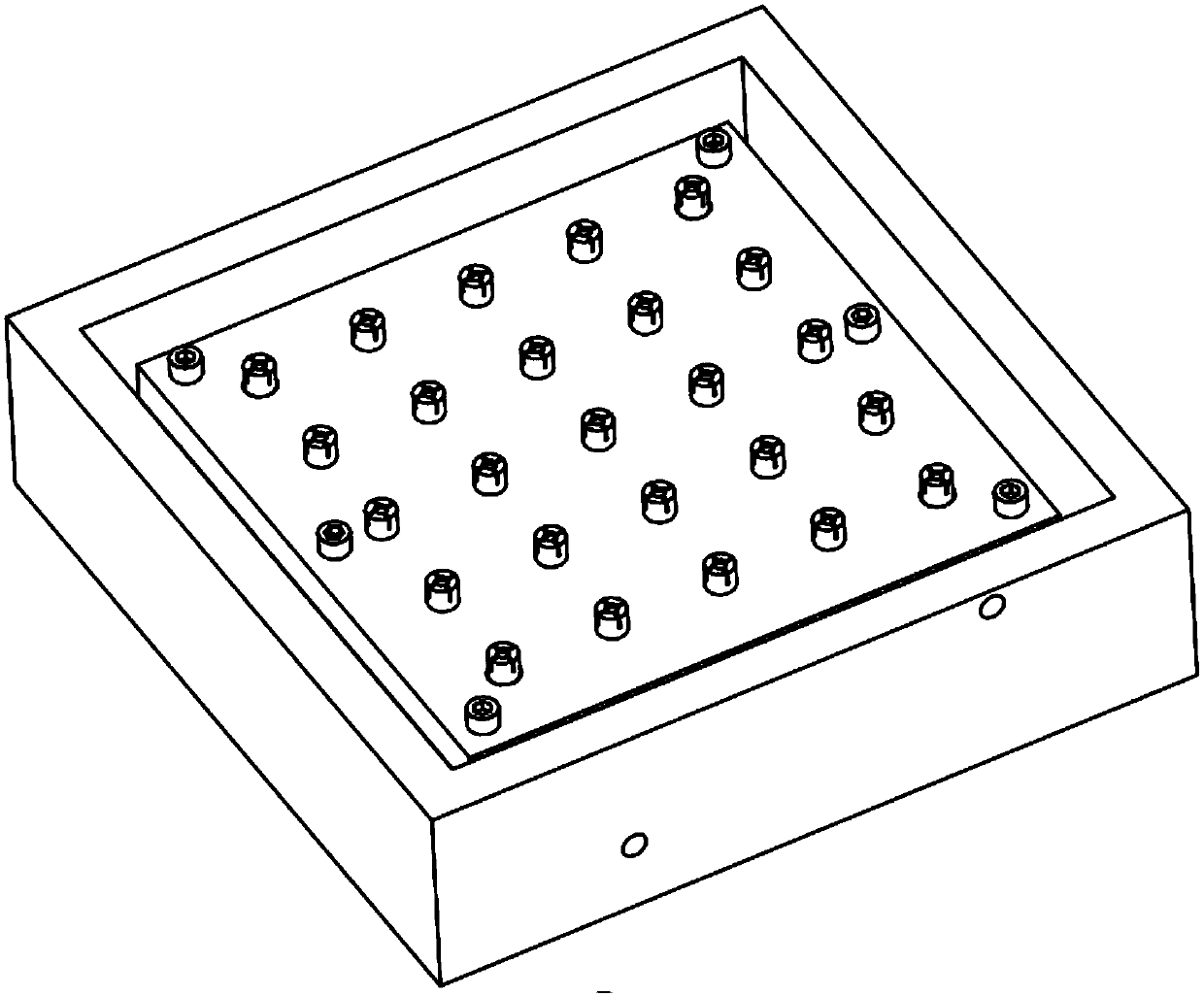

[0024] like figure 1 The shown clamping cooling device for laser quenching processing of steel plates includes a pool body 1 with a cooling medium inlet 1A and an outlet 1B, and the device erected on the pool body 1 by a support mechanism composed of long bolts 3A and 3B. Clamping platform 2; there is a fixed terminal 5 on the clamping platform 2, and a magnet 6 is embedded in the fixed terminal 5. figure 2 Schematic diagram of the overall use of the structure after assembly.

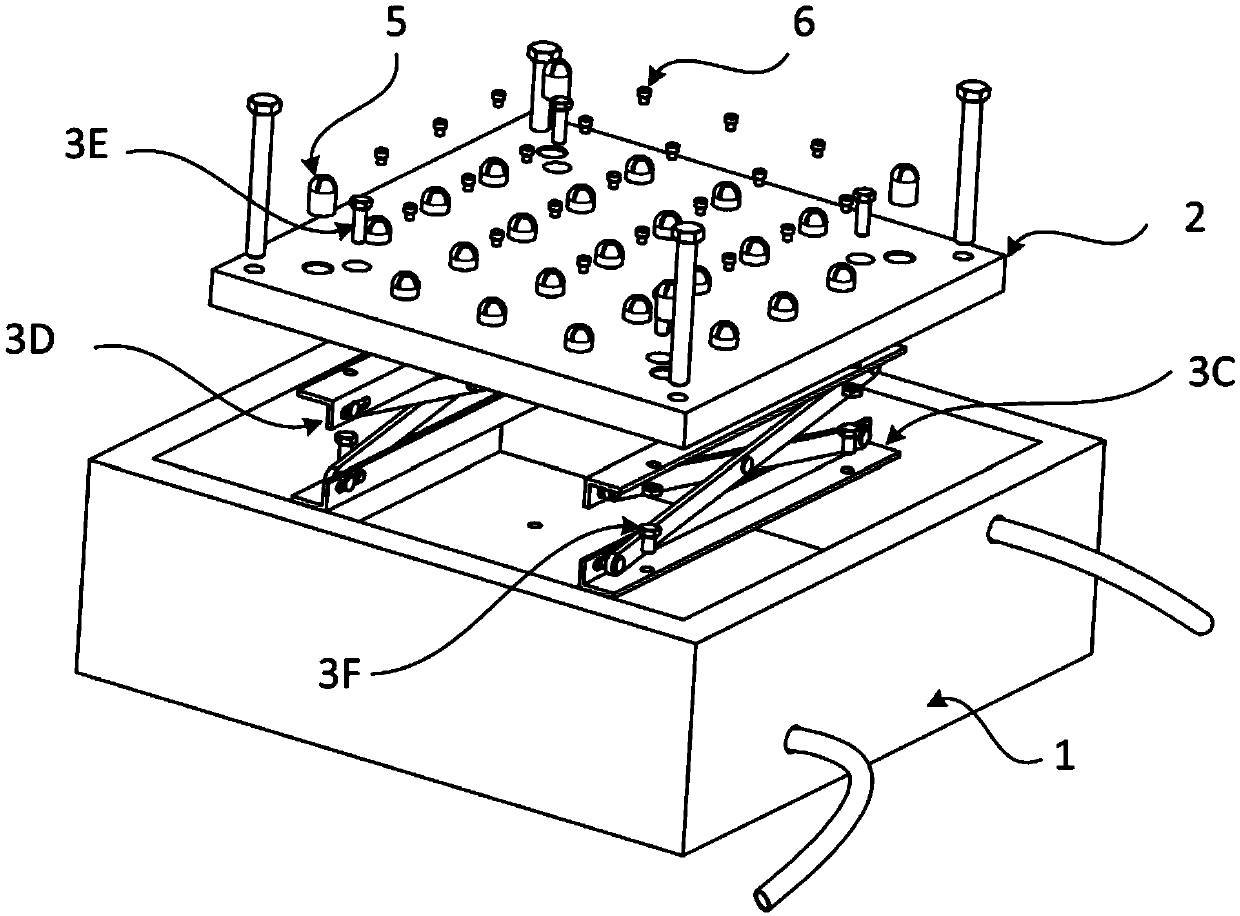

[0025] The further support mechanism is the X-type telescopic bracket 3C and 3D, the stationary end of the X-type telescopic bracket 3C and 3D is fixed in the pool body 1 by the bolt 3F, and the movable end is connected to the clamping platform 2 by the bolt 3E, and the clamping platform 2 has The fixed terminal 5 is embedded with a magnet 6 . Figure 4 It is a schematic diagram of the use of the supporting mechanism after the structure is assembled.

[0026] like figure 1 and 3 As shown: there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com