Multi-size steel wire ball production device

A technology for production equipment and steel balls, which is applied in the field of multi-size steel ball production equipment, can solve the problems of coil weight, inconsistent size, large labor costs, and long winding time, so as to facilitate popularization and use, reduce low efficiency, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

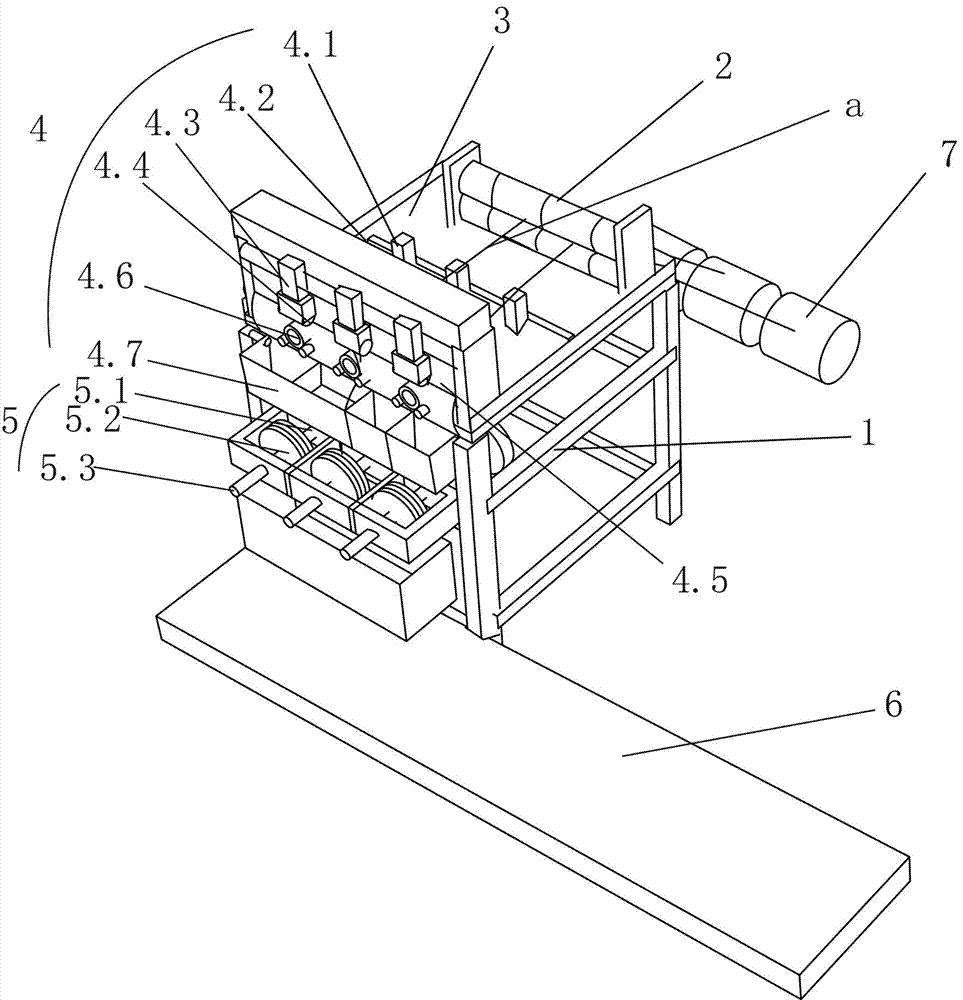

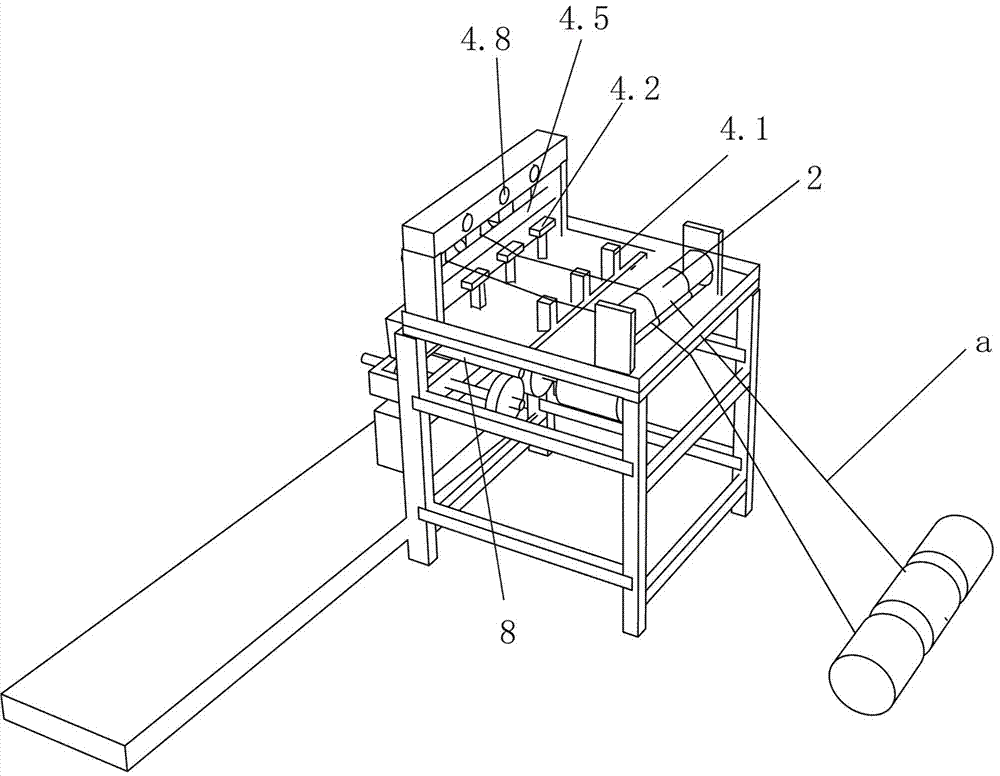

[0030] Such as figure 1 , is a schematic diagram of the overall structure of the present invention, the multi-size steel ball production equipment includes a frame 1, a support platform 3 is provided at the upper position of the frame 1, and a wire grinding roller shaft 2 is provided on the support platform 3, and the wire grinding roller shaft 2 The distance between the rollers can be adjusted, the width of the grinding roller shaft 2 is the same width as the support platform 3, and the grinding roller shaft is provided with a plurality of grooves, and the grooves divide the grinding roller shaft 2 into multiple sections .

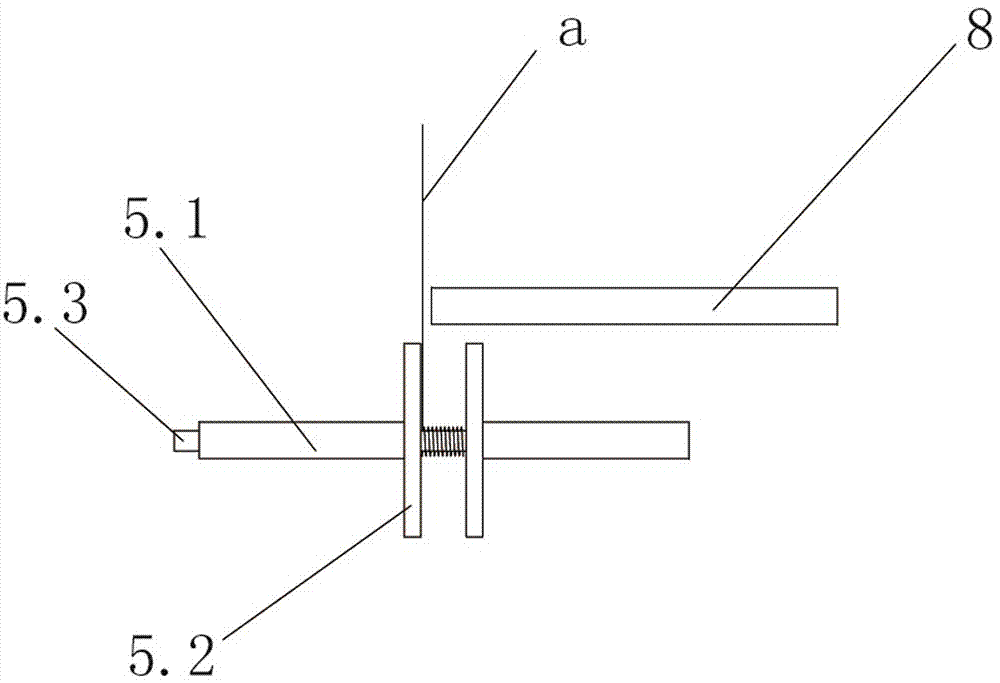

[0031] A wire drawing unit 4 is provided at the end of the support platform 3. The wire drawing unit 4 includes a first support member 4.1 and a first wire guide member 4.2. The pressing roller 4.4 is installed on the mounting frame 4.3. The frame 1 rotates, and the thread pressing roller 4.4 is tightly connected with the coarse roller 4.5. When necessar...

Embodiment 2

[0036] The difference from Embodiment 1 is that the first wire guide member 4.2 is provided with a wire clamping groove, and a steel wire detection system is provided at the wire clamping groove; the rolling of the wire stirring roller 5.2 is controlled by a PLC system, when When the steel wire detection system does not detect the presence of a steel wire within 1 minute, the PLC system automatically controls the corresponding spinning roller 5.2 to perform a power-off operation. The steel wire detection system arranged in the groove can be realized by using the existing PLC detection technology, and will not be described in detail again.

Embodiment 3

[0038] The difference from Example 1 is that the said grinding roller shaft 2 is two cylindrical roller shafts with unequal radii. For example, the diameter of the front part of the grinding roller shaft is 10cm, and the diameter of its tail is 13cm, so that the radius of the grinding roller shaft 2 changes, so that the steel wire rolled out does not have the same internal diameter.

[0039] The rest of the working methods and principles are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com