Connection structure capable of preventing petroleum pipeline from condensing

A technology for petroleum pipelines and connection structures, which is applied in pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve problems such as smaller pipe diameters, easy condensation and proliferation of liquids, and influence on petroleum liquid transportation, etc., to achieve acceleration Flow, improve sealing ratio, and reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

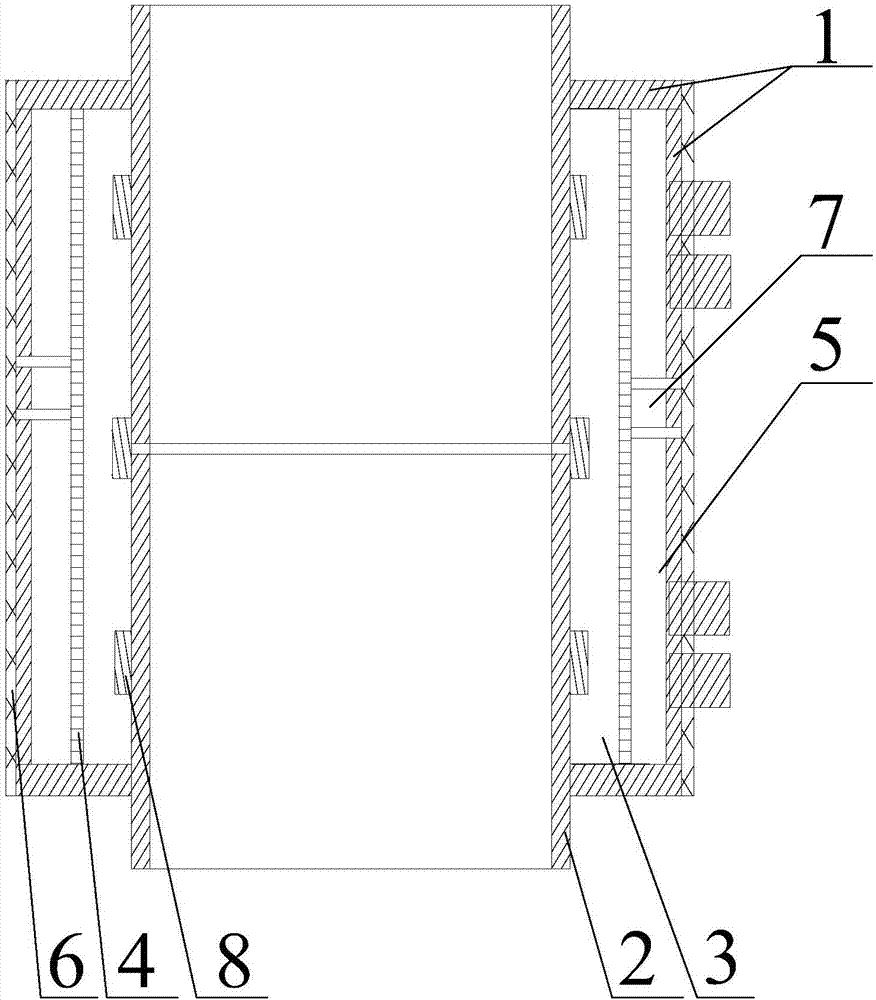

[0018] Such as figure 1 As shown, the present invention can prevent the connection structure of the oil pipeline condensation, including an annular connector 1, the inner diameter of the annular connector 1 matches the outer diameter of the oil pipeline 2, and an annular space is opened on the inner wall of the annular connector 1 In the annular cavity, a heat conduction layer 3, a heating layer 4, and a thermal insulation layer 5 are sequentially arranged in the direction away from the outer wall of the oil pipeline 2, and a layer of solar cells 6 is evenly arranged on the outer wall of the annular connector 1. , both the solar cells 6 and the heating layer 4 are connected to the power module 7 placed in the thermal insulation layer 5 . The thickness of the heat conducting layer 3 is 5 mm. There are three annular grooves in the heat conduction layer 3, the annular grooves are arranged at equal intervals in the axial direction of the annular connector 1 and the center line co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com