Particleboard sawing tooling and sawing process

A particleboard and sawing technology, which is applied in the field of particleboard sawing tooling and sawing technology, can solve the problems of inconvenient sawing saw blades and positioning of the particleboard to be sawed, and achieves convenient sawing control, simple and efficient operation, and moving trajectory. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

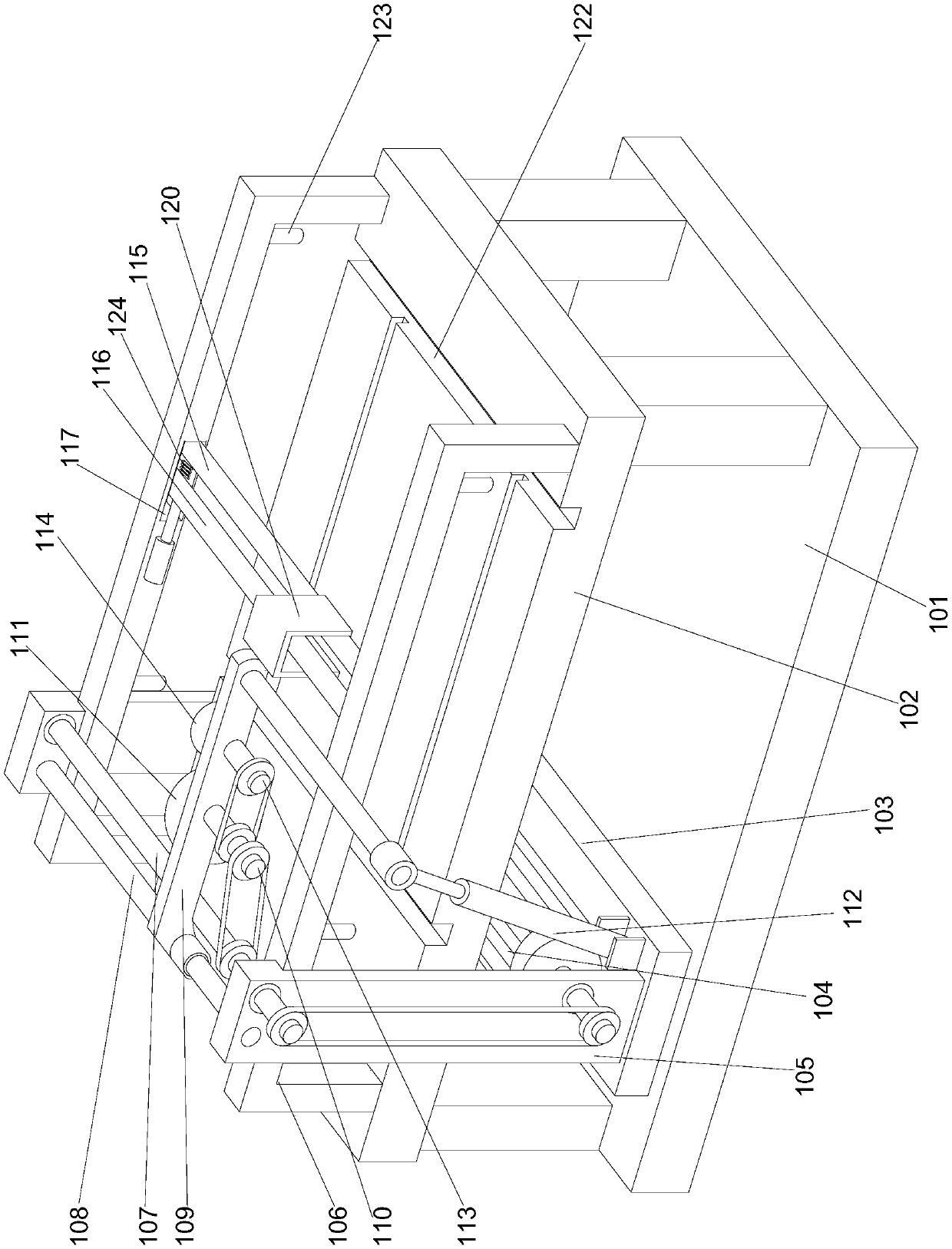

Embodiment 1

[0040] When the particleboard is thicker, it is difficult to align the sawing. Single saw blade sawing may easily cause the problem of rapid wear of the saw blade. In this embodiment, in order to reduce the wear of the saw blade, preferably, the saw blade The supporting plate 109 is provided with an auxiliary rotating shaft 113 at one end away from the base frame 108, and a pre-cutting saw blade 114 is arranged on the auxiliary rotating shaft 113. The outer diameter of the pre-cutting saw blade 114 is smaller than that of the saw blade. The outer diameter of 111, the main shaft 110 drives the secondary shaft 113 to rotate through a belt. In this embodiment, the end of the hydraulic cylinder is hinged to the end of the saw blade support plate away from the base frame, and when the hydraulic cylinder drives the saw blade support plate to rotate relatively, when the axes of the main shaft and the auxiliary shaft on the saw blade support plate are at the same height, The pre-cut sa...

Embodiment 2

[0043] In order to avoid relative movement of the particleboard, in this embodiment, the particleboard is fixed from above. Preferably, plate pressing mechanisms for pressing on the end faces of the particleboard are respectively provided above the two ends of the supporting board platform 102 in the longitudinal direction. Two sets of beams for mounting the platen mechanism are arranged inside the bracket 106. In this embodiment, a structure such as bolts can be used as the plate pressing mechanism so that it can be pressed onto the surface of the particle board.

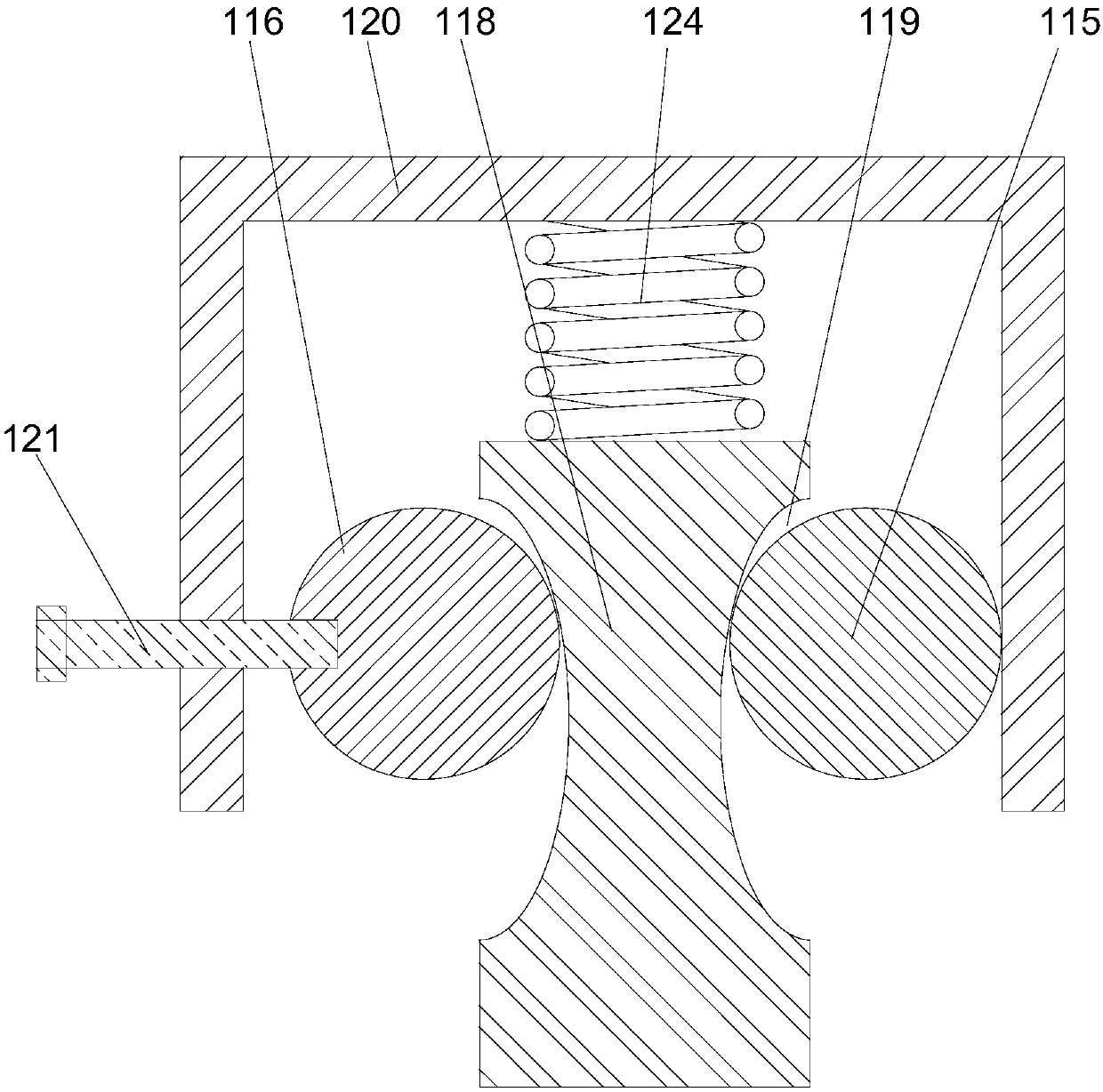

[0044] Further preferably, in this embodiment, a preferred structure of a plate pressing mechanism is disclosed. Preferably, each group of the beams is a fixed beam 115 and a movable beam 116 arranged in parallel, on the inner end surface of the bracket 106 A card slot 117 is provided, both ends of the fixed beam 115 and the movable beam 116 are respectively inserted into the inner side of the card slot 117, and both ...

Embodiment 3

[0049] In order to conveniently restrict the movement of the particle board in the horizontal direction, in this embodiment, preferably, wax melting grooves 122 are respectively provided at both ends of the support plate platform 102 in the longitudinal direction, and the support 106 is provided with The position of the wax melting tank 122 corresponds to the hot air nozzle 123. By using the wax melting tank, after the particleboard is installed on the support platform, the two ends of the particleboard are positioned above the middle of the wax melting tank, and liquid paraffin is injected into the wax melting tank, so that the paraffin can be attached to the particleboard when it solidifies on the edge of the particleboard The edge prevents the particle board from moving horizontally, which in turn makes the particle board more stable during the sawing process.

[0050] In this embodiment, the protection board is kept at a constant position. Since the hardness of the paraffin w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com