Surface modification method of silver powder for solar battery front silver paste

A technology of solar cells and surface modification, applied in conductive materials, circuits, photovoltaic power generation, etc. dispersed in non-conductive inorganic materials, can solve the problem that the hydrophobic properties, dispersibility and fluidity of silver powder cannot be improved at the same time, and the silver powder cannot be improved at the same time. Tap density, reduce contact resistance open circuit voltage and other issues, to achieve the effect of increasing photoelectric conversion efficiency, improving hydrodynamic performance, improving battery string resistance and open voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

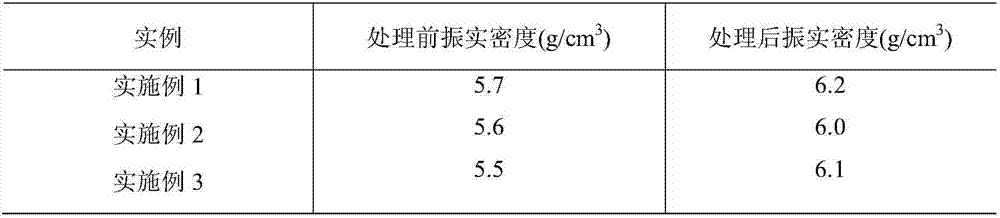

Embodiment 1

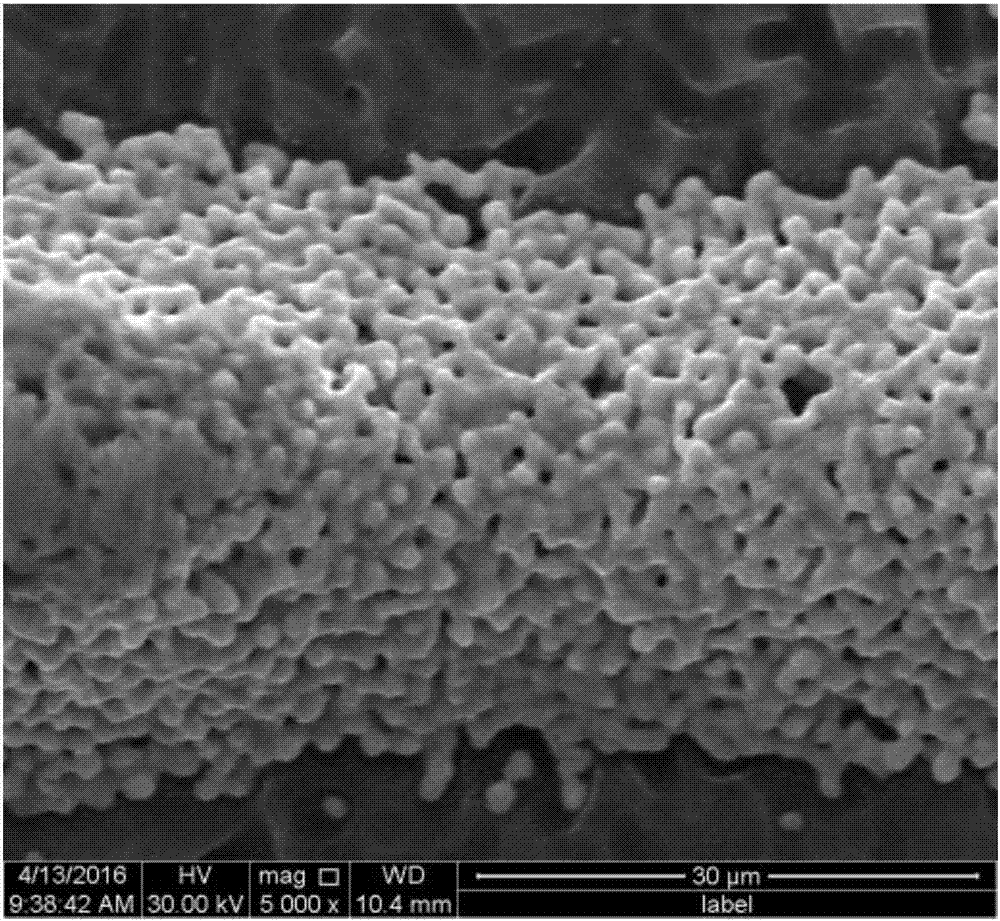

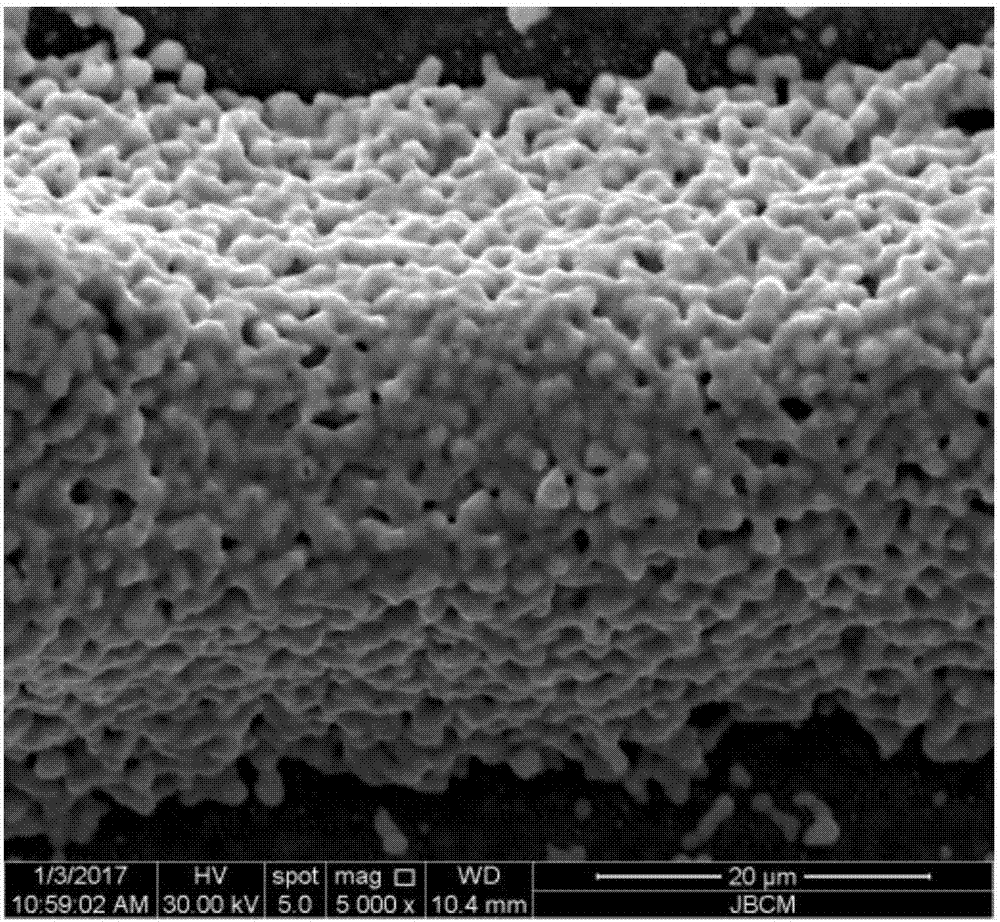

[0032] Example 1. Prepare surface treatment solution A: Weigh 1g of oleic acid and dissolve it in 100g of acetone; Surface treatment solution B: Stir evenly with 80g of ethanol and 20g of deionized water, add 1g of KH550 dropwise while stirring, KH550 is completely hydrolyzed; Mix treatment solution A and surface treatment solution B evenly, add 100g of 2μm silver powder, stir for 20min; settle completely, remove the supernatant, wash twice with absolute ethanol, dry in a drying oven at 80°C for 30min, and pass through a 100-mesh sieve .

Embodiment 2

[0033]Embodiment 2, prepare surface treatment solution A: Weigh 1g stearic acid and dissolve in 100g ethanol; Surface treatment solution B: Stir 80g ethanol and 20g deionized water evenly, add 1g KH550 dropwise while stirring, KH550 is completely hydrolyzed; Mix surface treatment solution A and surface treatment solution B evenly, add 100g of 2μm silver powder, stir for 20 minutes; settle completely, remove supernatant, wash with absolute ethanol twice, dry in a drying oven at 80°C for 30 minutes, and pass through a 100-mesh sieve network.

Embodiment 3

[0034] Example 3, preparation of surface treatment solution A: Weigh 1g of zinc stearate and dissolve in 100g of benzene; surface treatment solution B: 80g of ethanol and 20g of deionized water are stirred evenly, and 1g of KH550 is added dropwise while stirring, and KH550 is completely hydrolyzed; Mix the surface treatment solution A and the surface treatment solution B evenly, add 100g of 2μm silver powder, stir for 20min; settle completely, remove the supernatant, wash twice with absolute ethanol, dry in a drying oven at 80°C for 30min, and pass through 100 mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com