Kitchen waste anaerobic pretreatment device and method

A pretreatment device, a technology of kitchen waste, applied in the direction of solid waste removal, etc., can solve the problem of poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

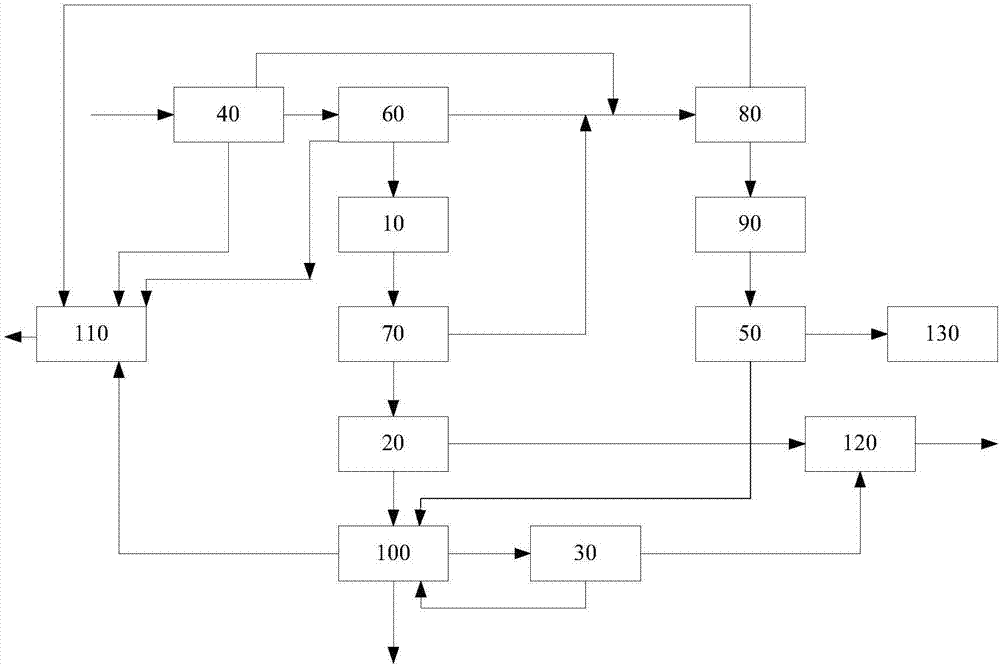

Image

Examples

Embodiment 1

[0067] 1) The food waste transport truck dumps the materials into the silo, and the chain-plate conveyor at the bottom of the silo transports the materials to the roller crusher. During the conveying process, the chain-plate conveyor filters out most of the free wastewater through the plate gap; The silo is equipped with an automatic opening and closing cover. The conveying equipment under the silo adopts a chain conveyor, and the gap between the chain conveyors is 8mm. Each chain plate is equipped with a scraper baffle, and the height of the baffle is 150mm. The free wastewater filtered out by the clearance of the guide plate of the water receiving tank is set under the surface;

[0068] 2) The food and kitchen materials are roughly crushed in the double-roll crusher, and the hard-to-break impurities can be removed in it to avoid damage to the integrated machine; the double-roll crusher is provided with an inspection port to facilitate the cleaning of unbreakable impurities, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com