Cage-shaped microbial filler structure and biochemical pool

A technology of microorganisms and microbial carriers, applied in biological water/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve problems such as poor water treatment effect and uneven distribution of sludge, and improve the efficiency of sewage treatment , Increase the amount of activated sludge, the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] The present application also provides an implementation mode, specifically as follows:

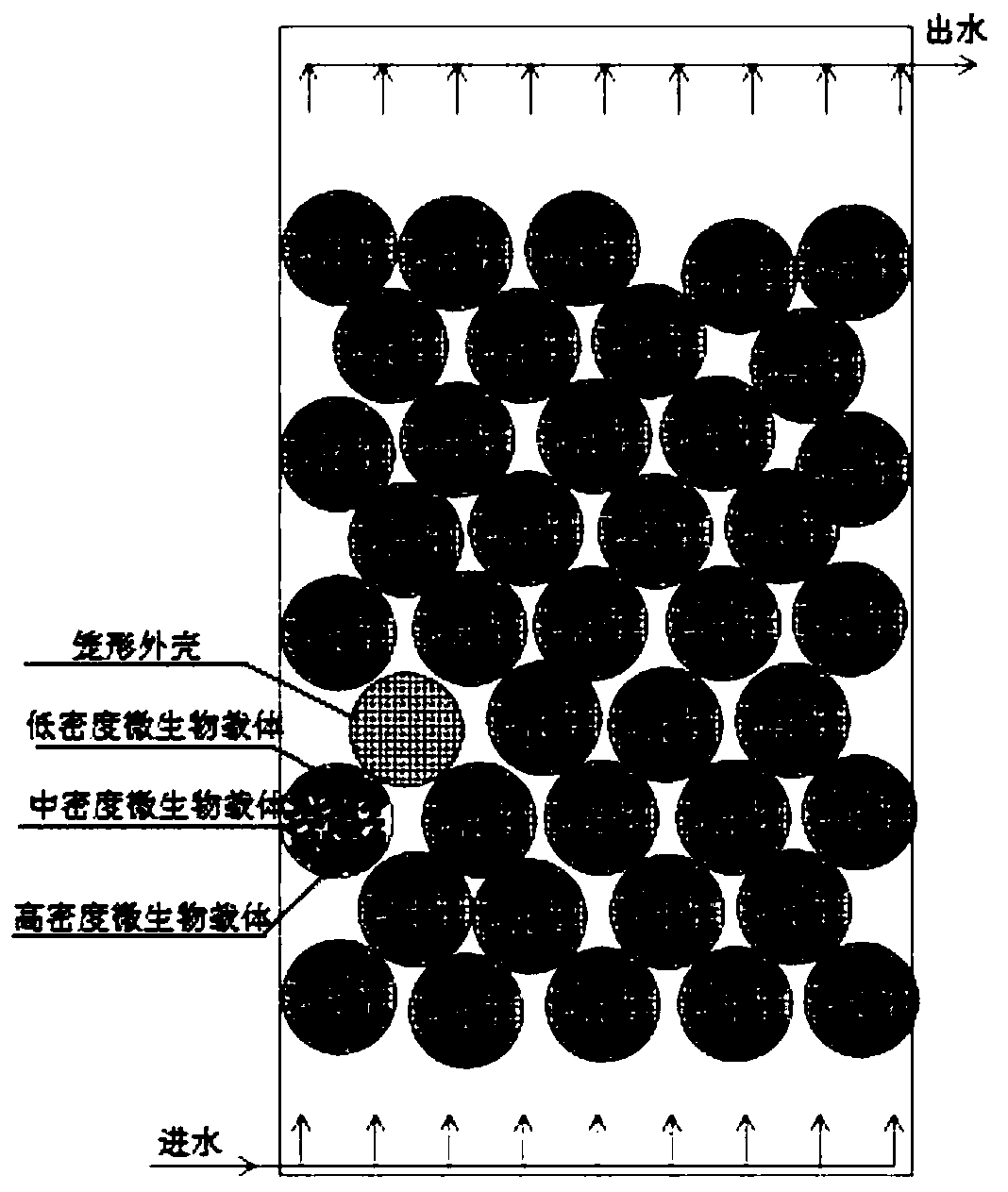

[0030] like figure 2 , image 3 As shown, in this embodiment, the cage-shaped shell is a sphere, which is woven with warp and weft threads; it is divided into two hemispheres, and the two hemispheres are assembled into one body with a connecting piece. The cage-shaped shell combined by buckles can be used to envelop the microbial carrier. The distance between two adjacent weft threads does not exceed the outer diameter of the microbial carrier. Specifically, the diameter of the cage-shaped shell is 1000 mm, and the distance between two adjacent weft threads is 14 mm. The cage-shaped shell provided in this embodiment can envelop the microbial carrier in the cage, for example, the size of the microbial carrier is 20mm*20mm*20mm or 40mm*40mm*40mm.

[0031] The present invention also provides a biochemical pool comprising the cage-shaped microbial filler structure, wherein multiple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com