Material screening device for chemical raw material and medicine processing

A technology of chemical raw materials and screening devices, which is applied in the fields of filtering, chemical instruments and methods, separating solids from solids with airflow, etc. It can solve the problem of adjusting and determining the natural frequency of vibration motors, and cannot use vibration energy reasonably. To achieve the vibration effect and other problems, to achieve the effect of improving conversion, preventing dust, and effective vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

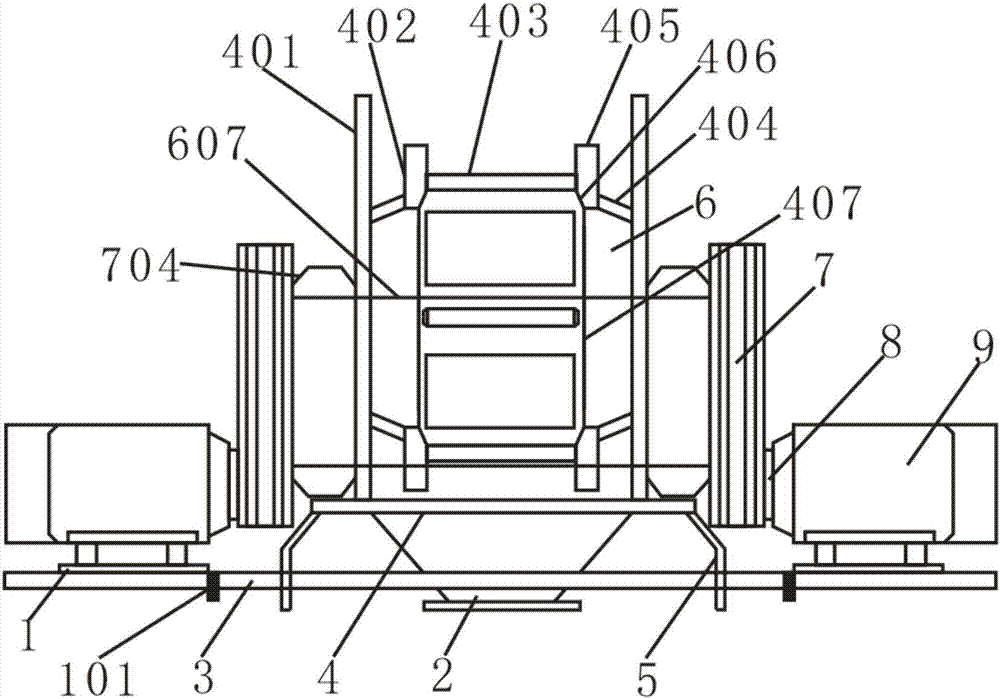

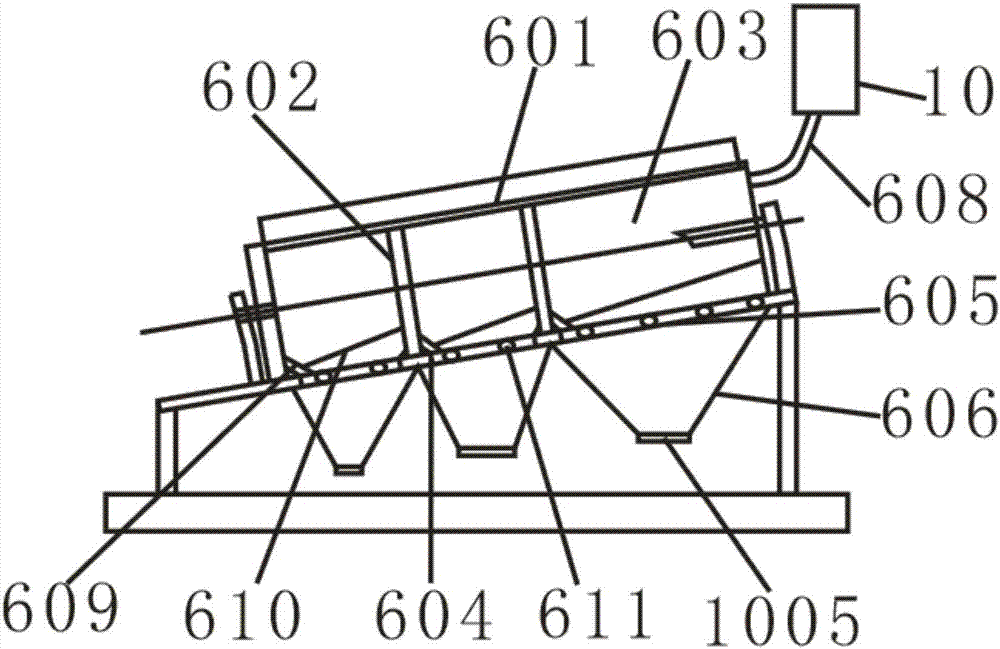

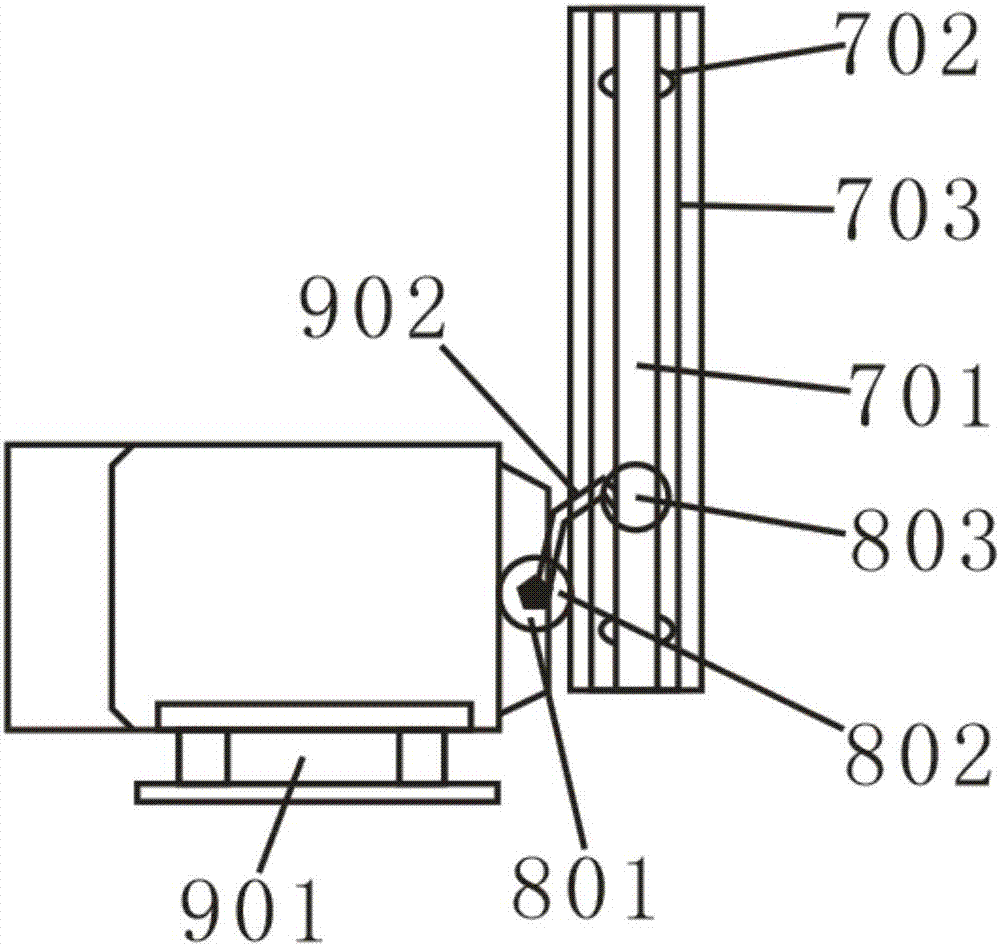

[0034] like Figure 1 to Figure 4 As shown, the present invention provides a material screening device for chemical raw materials and pharmaceutical processing, including a vibration table 1, a load-bearing substrate 2, a vibration screening device 6, a crankshaft vibration transmission device 8, a vibration motor 9, and a feeding device 10, An extension support arm 3 is fixedly installed at the bottom of the vibration table 1, and the extension support arm 3 penetrates and is fixed inside the load-bearing substrate 2; the number of vibration tables 1 is two, and the extension support arm 3 is fixed on the load-bearing substrate 2 as a symmetrical axis Above, the vibration screening device 6 is set on the vibrating table 1 through the mounting base 901; the load-bearing substrate 2 is in the shape of a round table, the bracket 4 is fixedly installed on the top of the load-bearing substrate 2, and the extension support frame is fixedly installed on the bottom of both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com