Method of calculating fatigue life of flexible bearing by utilizing finite element modeling

A flexible bearing and fatigue life technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of no flexible bearing simulation method, long experiment time, low applicability, etc., to shorten the development cycle and analyze quickly , without loss of calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

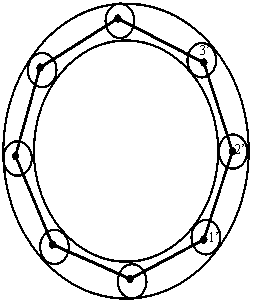

[0035] Embodiment 1: Referring to Figures 1 to 5, the present invention uses finite element modeling to calculate the fatigue life of a flexible bearing, which is characterized in that the operating steps are as follows:

[0036] Step 1): Draw the geometric three-dimensional model of the flexible bearing and the camshaft in the UG software, and save it as bearing.stp format;

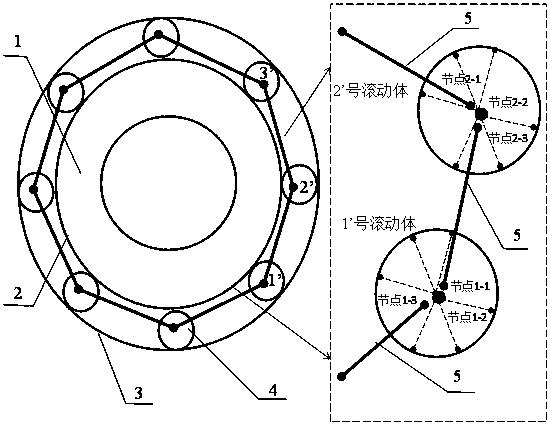

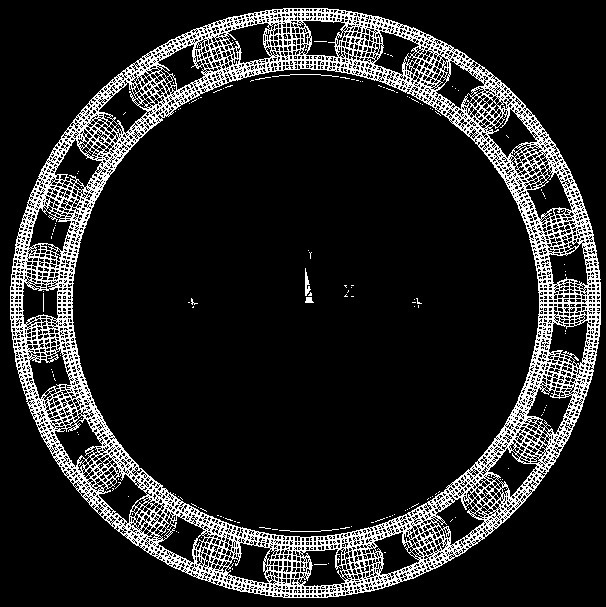

[0037] Step 2): Open the ANSYS software, import the bearing.stp geometric three-dimensional model, divide the inner ring (2), outer ring (3), rolling element (4), and camshaft (1) into hexahedral meshes, and (1)-inner ring (2), inner ring (2)-rolling body (4), outer ring (3)-rolling body (4) set contact relationship;

[0038] Step 3): Add link unit (5) instead of bearing cage;

[0039] Step 4): Apply loads and constraints in the finite element model;

[0040] Step 5): Import the finite element model into the engineering analysis software ANSYS to perform multi-body contact analysis;

[0041] Step 6): ...

Embodiment 2

[0042] Embodiment two: the present embodiment is basically the same as embodiment one, and the features are as follows:

[0043] The specific method of adding the link unit to replace the bearing cage is as follows:

[0044] Step ①: Generate three nodes at the center position of each rolling body. The three nodes generated by No. 1 rolling body can be called 1-1, 1-2, 1-3; the names of the nodes generated by No. 2 rolling body The three nodes are called 2-1, 2-2, 2-3...; the number of flexible bearing rolling elements is 23, so a total of 69 nodes are generated;

[0045] Step ②: Among the nodes generated above, couple the translational degrees of freedom of the nodes at the same position, and the rotational degrees of freedom of the nodes at the same position can be different; the X, The translational degrees of freedom in the Y and Z directions are the same, but the rotational degrees of freedom can be different;

[0046] Step ③: connect the nodes between the adjacent rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com