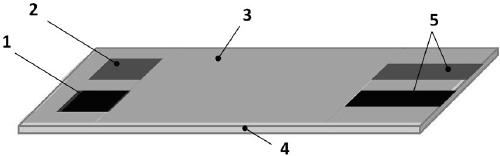

Glucose oxidase screen-printed electrode for on-line monitoring and preparation method thereof

A technology of screen printing electrodes and oxidase screens, applied in biochemical equipment and methods, measuring devices, electrochemical variables of materials, etc., can solve the problems of online analysis of glucose biosensors, difficulty in batch, industrial production, and difficulty in multiple times Analyze and test problems, achieve the effect of simple and cheap synthesis equipment, short synthesis time and ideal reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Detection of Glucose Standards

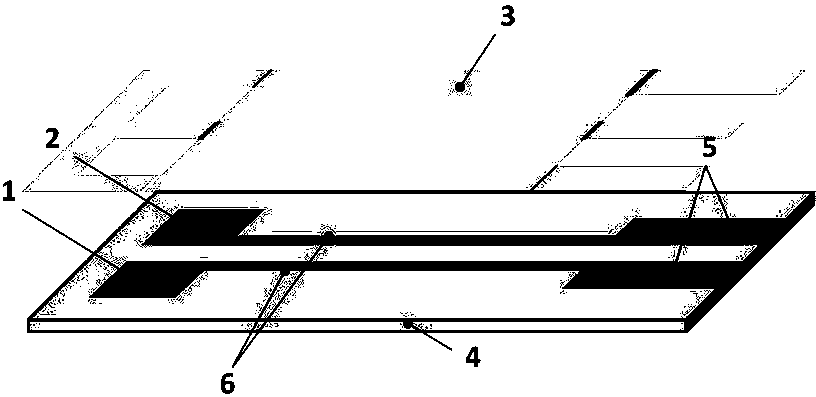

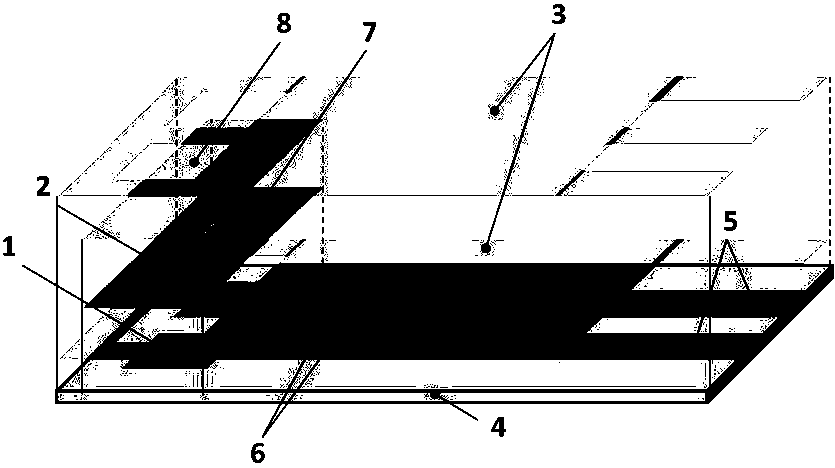

[0038] 1) Fabrication of Prussian blue-doped mediator-type hydrogen peroxide screen-printed electrodes:

[0039] Preparation containing equimolar concentration of K 3 Fe(CN) 6 And the aqueous solution of KCl, adjust its pH in the scope of 1.0-2.5 with hydrochloric acid, add 1-1.33 times of volumes containing the FeCl of equimolar concentration dropwise to it under rapid stirring condition 3 The aqueous solution is centrifuged at 4000 rpm after fully reacting to obtain the dark blue substance, that is, Prussian blue; it is dried in an oven at 95°C to constant weight, and then baked in the same oven at 100°C-150°C for 0.5-2h to obtain Activated Prussian blue, after cooling in a desiccator, grind it into granules with a mortar for later use; weigh 0.05g of Prussian blue granules, mix it with 1mL N,N-dimethylformamide, grind it in a mortar, then add 3g Conductive carbon paste and 2mL of special solvent for conductive carbon paste are fine...

Embodiment 2

[0056] 1) Fabrication of Prussian blue-doped mediator-type hydrogen peroxide screen-printed electrodes:

[0057] Prepared with equimolar concentration of K 3 Fe(CN) 6 And the aqueous solution of KCl, adjust its pH in the scope of 1.0-2.5 with hydrochloric acid, add 1-1.33 times of volumes containing the FeCl of equimolar concentration dropwise to it under rapid stirring condition 3 The aqueous solution is centrifuged at 4000 rpm after fully reacting to obtain the dark blue substance, that is, Prussian blue; it is dried in an oven at 95°C to constant weight, and then baked in the same oven at 100°C-150°C for 0.5-2h to obtain Activated Prussian blue, after cooling in a desiccator, grind it into granules with a mortar for later use; weigh 0.05g of Prussian blue granules, mix it with 1mL N,N-dimethylformamide, grind it in a mortar, then add 3g Conductive carbon paste and 2mL of special solvent for conductive carbon paste are finely ground for 20 minutes to fully mix the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com