A coaxial structure of supercritical carbon dioxide centrifugal compressor and axial flow turbine

A centrifugal compressor and carbon dioxide technology, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of increased cost, difficult matching of high-speed motors, high motor requirements, etc., to reduce equipment manufacturing and system operating costs, and improve application Sex and economy, and the effect of reducing the quality of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

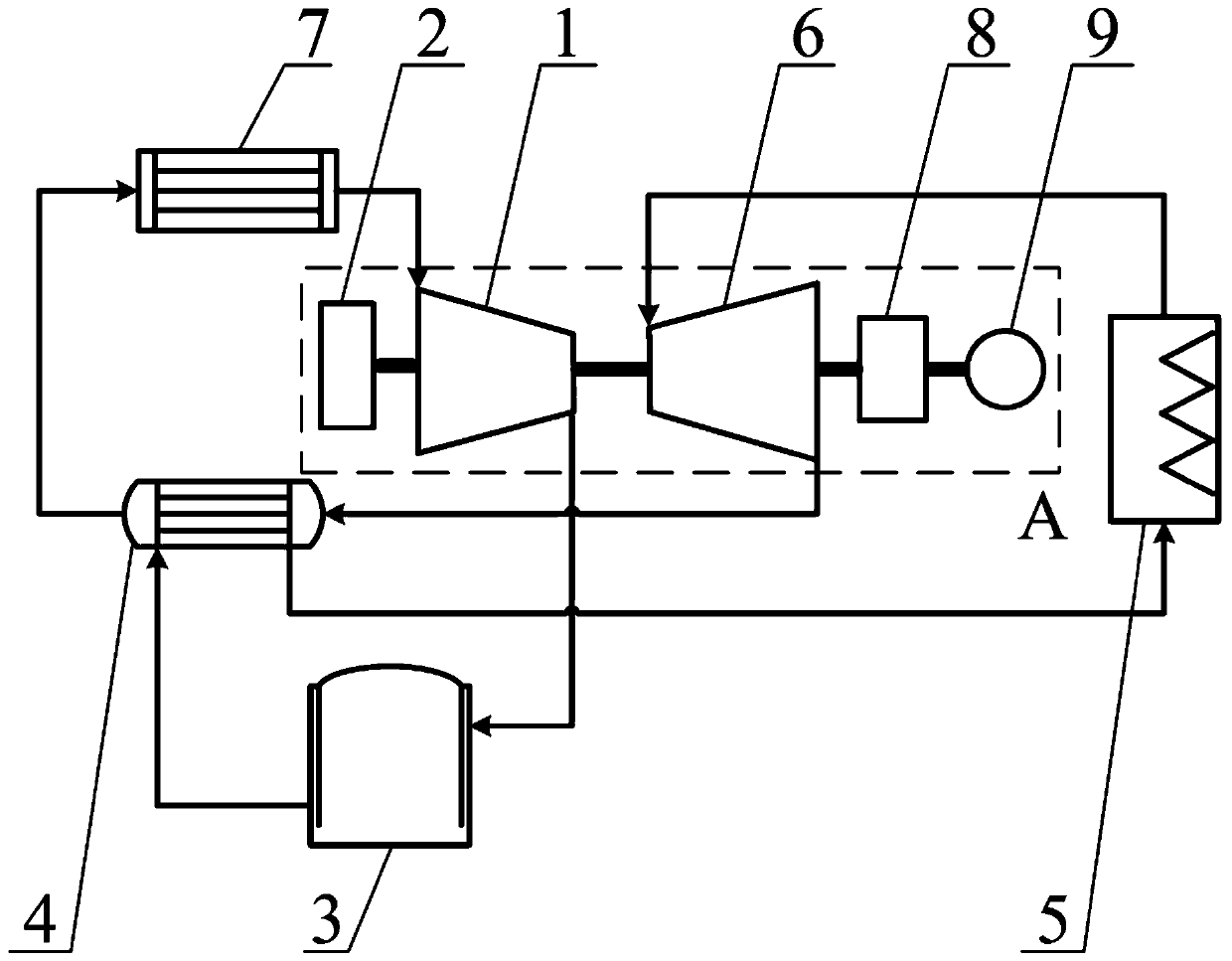

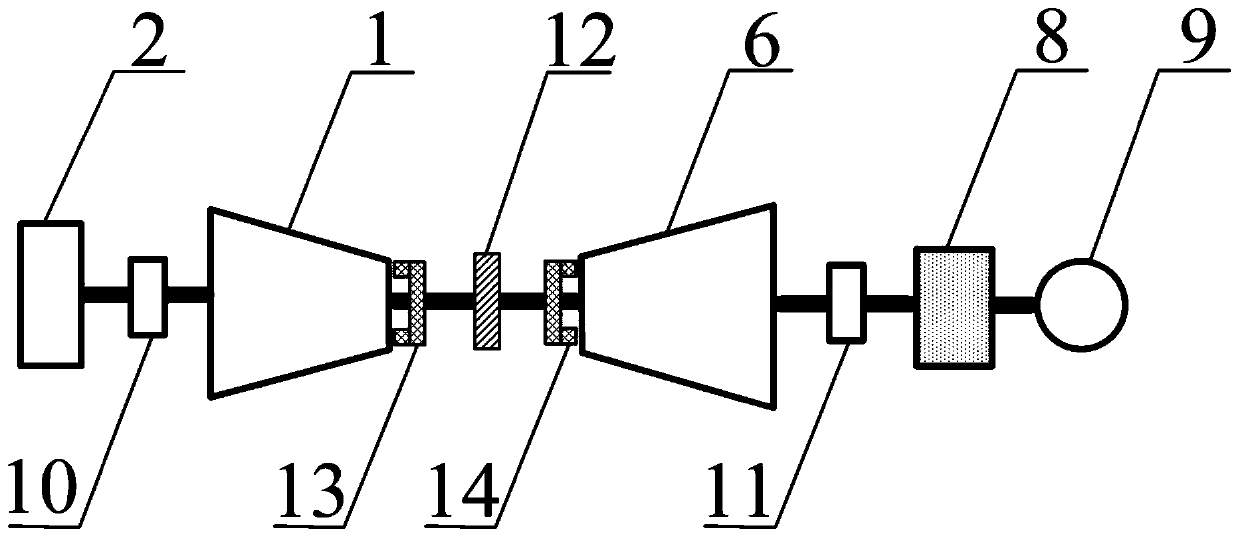

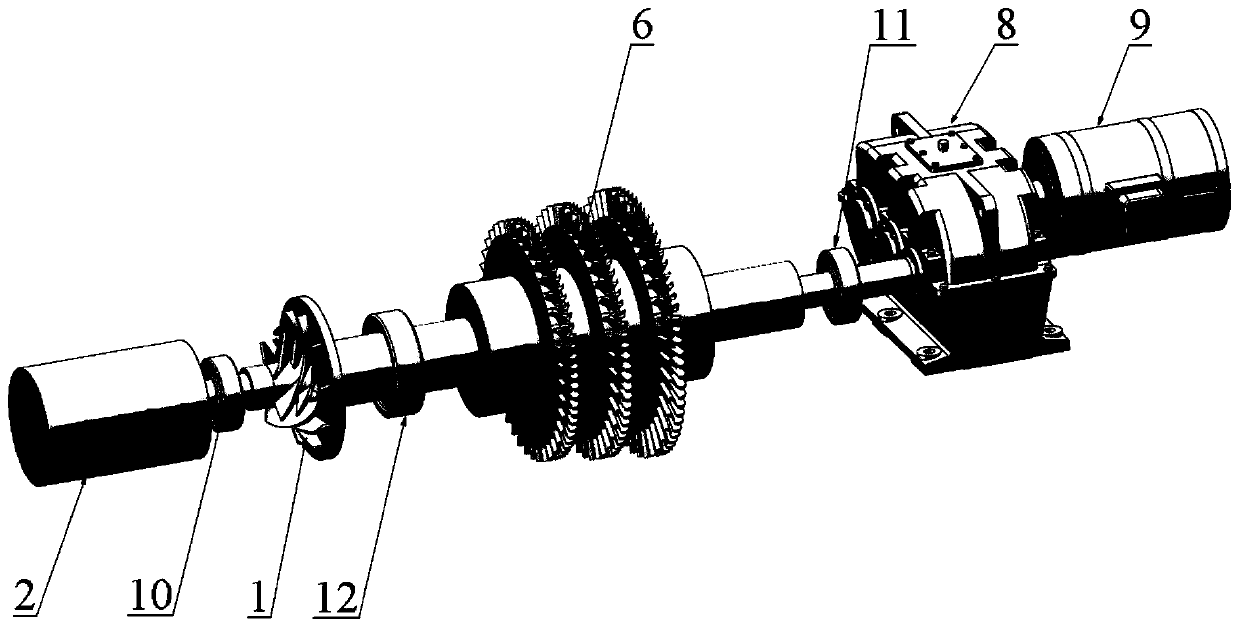

[0028] Such as Figure 1 to Figure 3 As shown, a supercritical carbon dioxide centrifugal compressor provided by the present invention has a coaxial structure with an axial flow turbine, including a centrifugal compressor 1, a high-speed starting motor 2, a surge tank 3, a regenerator 4, a heat source 5, an axial flow Turbine 6, cooler 7, gearbox 8, generator 9, compressor side radial bearing 10, turbine side radial bearing 11, thrust bearing 12, compressor side dry gas seal 13 and turbine side dry gas seal 14. Among them, the centrifugal compressor 1, the high-speed starter motor 2 and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com