Constraint type assembly compound concrete filled-steel tubular column and steel beam joints provided with reinforcing blocks

A technology of steel pipe concrete columns and reinforcement blocks, which is applied in the direction of construction and building construction, which can solve the problems of increasing the cost of building structures, tearing of the web, and long time consumption, so as to reduce the difficulty and workload of construction and strengthen the connection of beams and columns The effect of simple and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

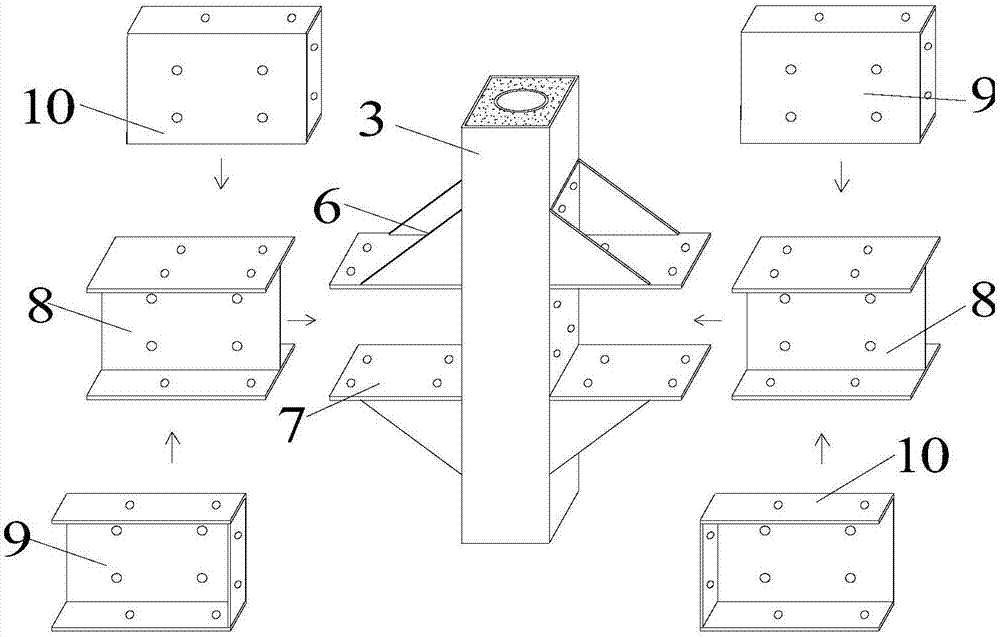

[0044] like figure 1 As shown, this embodiment provides a kind of splicing application of a "ten"-shaped joint 1 in a frame structure of a constrained composite steel pipe concrete column-steel beam provided with reinforcing blocks. The "ten"-shaped joint 1 includes There are composite steel pipe concrete columns 5, first beam end connectors 6, second beam end connectors 7, first reinforcement blocks 9 and second reinforcement blocks 10; wherein, each of the four sides of the composite steel pipe concrete column 5 is provided with A first beam end connector 6 and a second beam end connector 7, a steel beam 8 is inserted between the two beam end connectors, and a first reinforcement block 9 and a second reinforcement block 10 are embedded on both sides of the steel beam The steel beams are clamped and connected to the composite steel pipe concrete column 5, and all connections are high-strength bolt connections.

Embodiment 2

[0046] like figure 2 As shown, this embodiment provides a constrained composite steel pipe concrete column-steel beam with reinforcing blocks, where the splicing application of the "T"-shaped node 2 in the frame structure, the "T"-shaped node 2 includes a composite Concrete-filled steel pipe column 5, first beam end connector 6, second beam end connector 7, first reinforcement block 9 and second reinforcement block 10; wherein, each of the three sides of the composite steel pipe concrete column 5 is provided with a first A beam end connector 6 and a second beam end connector 7, a steel beam 8 is inserted between the two beam end connectors, and the first reinforcement block 9 and the second reinforcement block 10 are embedded and clamped on both sides of the steel beam Steel girders are connected with composite steel pipe concrete columns 5, and all connections are high-strength bolt connections.

Embodiment 3

[0048] like image 3 As shown, this embodiment provides a kind of splicing application of a "one"-shaped node 3 in a frame structure of a constrained composite steel pipe concrete column-steel beam provided with reinforcing blocks. The "one"-shaped node 3 includes There are composite steel pipe concrete columns 5, first beam end connectors 6, second beam end connectors 7, first reinforcement blocks 9 and second reinforcement blocks 10; wherein, each of the two opposite sides of the composite steel pipe concrete column 5 A first beam end connector 6 and a second beam end connector 7 are arranged on the side, a steel beam 8 is inserted between the two beam end connectors, and the first reinforcement block 9 and the second reinforcement block are placed on both sides of the steel beam. 10 is embedded with clamped steel beams and connected with composite steel pipe concrete columns 5, and all connections are high-strength bolt connections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com