Preparation method for low-molecular weight ascophyllum mackaii glycan and application

A technology of alcophyllan and low molecular weight, which is applied in the field of low molecular weight seaweed polysaccharide preparation, can solve the problems of shedding of active groups, loss of activity, change of polysaccharide three-dimensional structure, etc., and achieves the effect of mild reaction conditions and weak destructive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention discloses a preparation method of low molecular weight ascophyllan, comprising the following steps:

[0026] Step 1, preparation of Ascophyllum nodosum powder:

[0027] Washing, drying, and pulverizing the Ascophyllum nodosum, passing through a 60-mesh standard sieve to obtain the Ascophyllum nodosum powder;

[0028] Step 2, preparation of ascophyllan dry powder:

[0029] Weigh 30g of Ascophyllum nodosum powder, add deionized water according to the weight volume ratio of 1:30g / mL, extract at 100°C, stir continuously for 2h during the extraction process, centrifuge at 5000×g for 20min after cooling, take the supernatant, add 3M HCL to make the final concentration pH 1.3, centrifuge to remove the alginic acid precipitate, collect the supernatant, add absolute ethanol to make the final concentration 50% by volume, centrifuge overnight, take the precipitate, dialyze and freeze-dry, and obtain the foam Phyllophyllan dry powder;

[0030] Step 3. Enzymatic hyd...

Embodiment 2

[0034] Embodiment 2 single factor enzymatic hydrolysis experiment

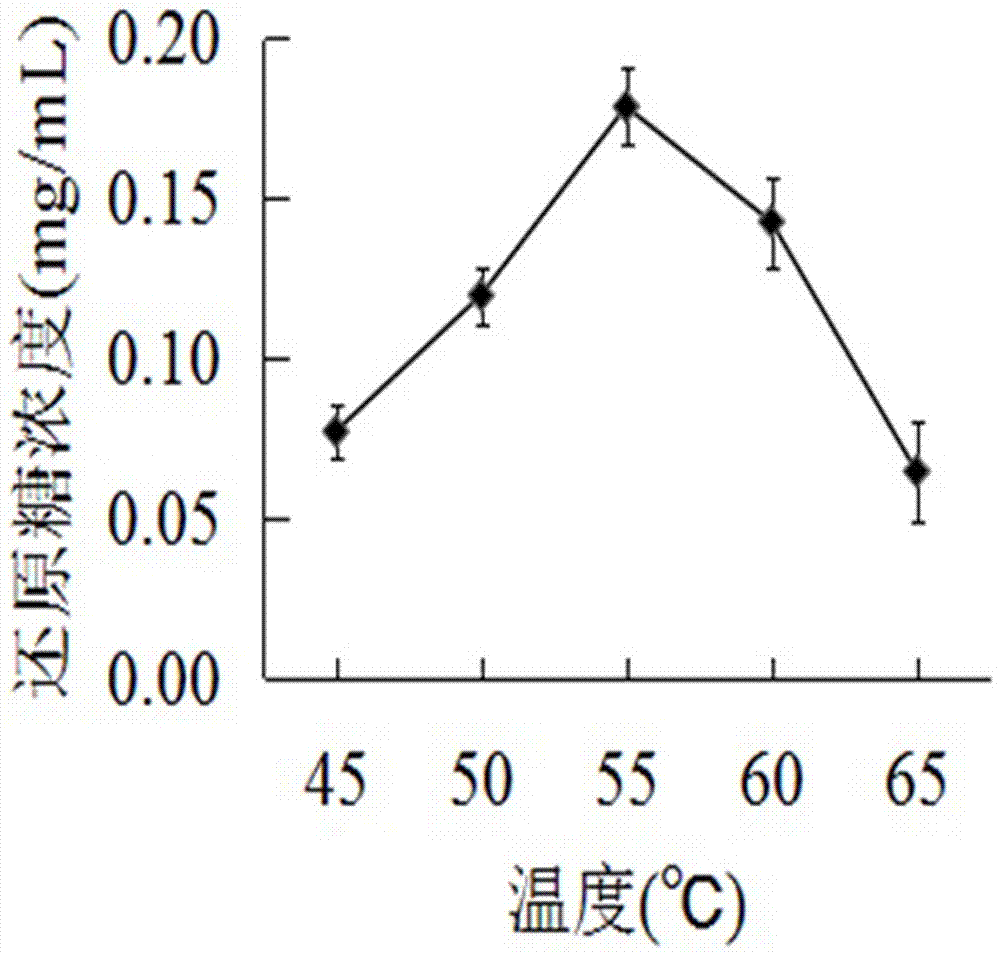

[0035] 2.1 The effect of temperature on the degradation of ascophyllan by cellulase

[0036] In Step 3 of Example 1, the effects of different temperatures of 45°C, 50°C, 55°C, 60°C, and 65°C on the degradation of Ascophyllan by cellulase were investigated, such as figure 1 As shown, at 55°C, the reducing sugar concentration is the highest, that is, the enzymatic hydrolysis efficiency is the highest.

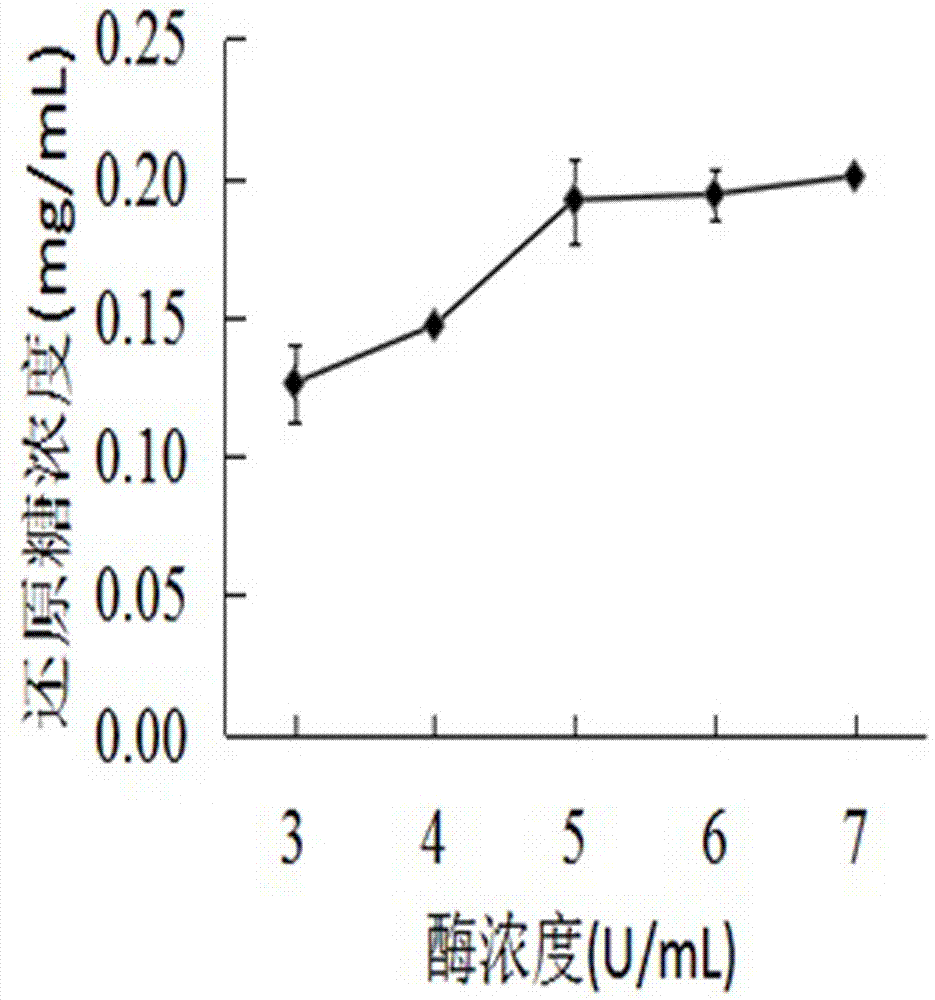

[0037] 2.2 The effect of enzyme concentration on the degradation of ascophyllan by cellulase

[0038] In Step 3 of Example 1, the influence of different enzyme concentrations 3U / ml, 4U / ml, 5U / ml, 6U / ml, and 7U / ml on the degradation of Ascophyllan by cellulase was investigated, such as figure 2 As shown, when the enzyme concentration is 5 U / ml, the reducing sugar concentration is the highest, that is, the enzymatic hydrolysis efficiency is the highest.

[0039] 2.3 The effect of pH on the degradation of ascoph...

Embodiment 3

[0042] The 0.5g ascophyllan dry powder prepared in step 2 of Example 1 was degraded by cellulase, alginate lyase, and xylanase to obtain low molecular weight ascophyllan fragments, respectively, and the oligomeric polysaccharides containing the different molecular fragments were respectively The ascophyllan aqueous solution adopts a small-scale ultrafiltration membrane separation device to separate the oligomeric ascophyllan of different molecular weights, and the peristaltic pump transports the oligomeric ascophyllan aqueous solution of the different molecular fragments to a molecular cut-off of 5.3L / min. 10kDa hollow modified polyvinyl chloride membrane for separation, pressure, when the solution volume is concentrated to 1 / 6, stop the ultrafiltration, collect the solution with a molecular cut-off of 10kDa, and when it is concentrated to 1 / 6 by rotary evaporation, stop the concentration, and Collect the concentrated solution to obtain the oligomeric Ascophyllan component with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com