Working method of automatic oil sucking and changing equipment

A working method and equipment technology, which is applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as inaccurate oil filling, oil leakage and adhesion, and dust adhesion on the outer wall of the oil filling port, so as to avoid manual labor. Oil injection operation, quality assurance, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

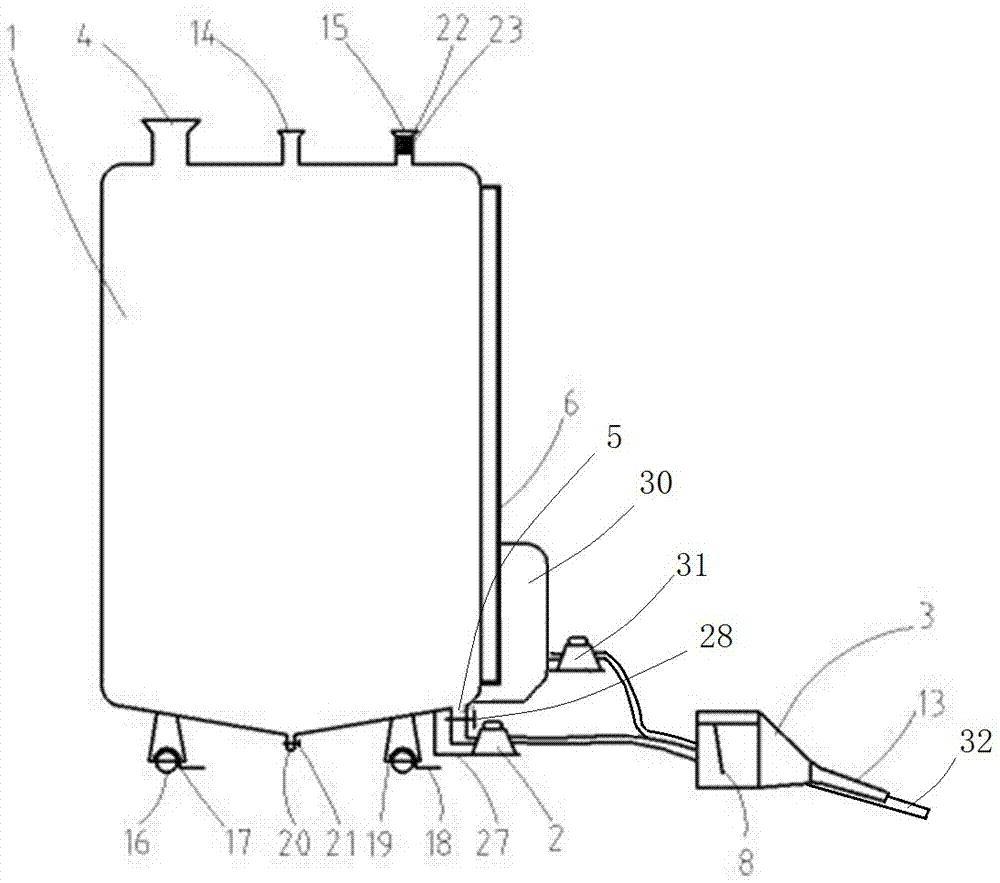

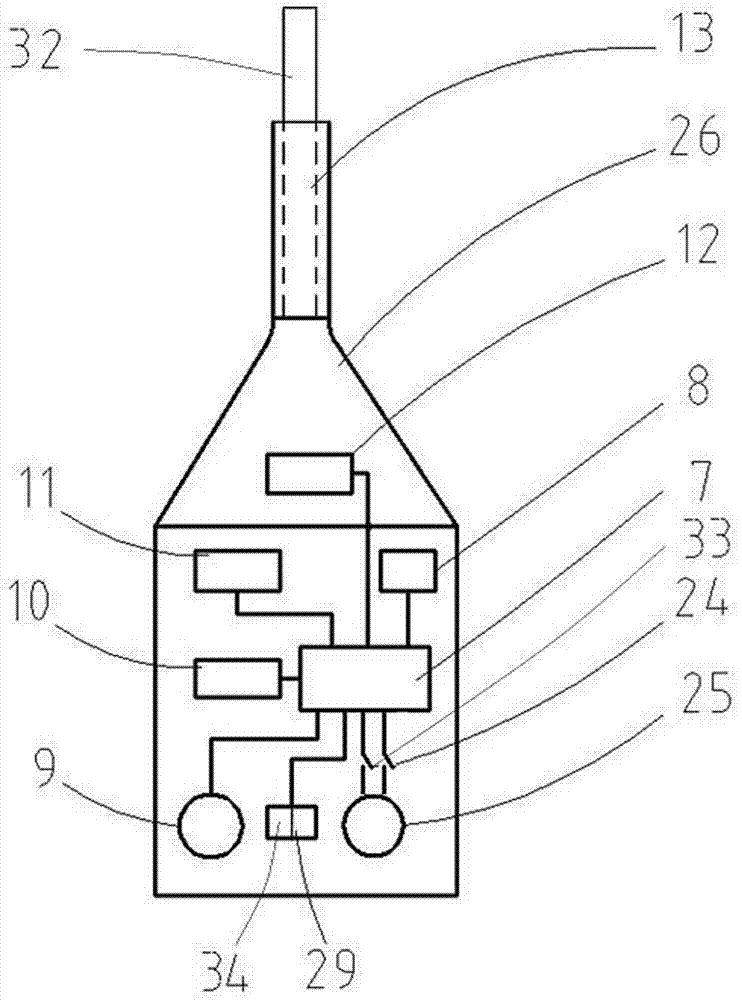

[0024] The invention discloses a working method of an automatic oil-suction and oil-changing device. The structure is as follows: figure 1 and figure 2 shown, including the following steps:

[0025] a. When using the equipment for the first time, open the oil cover of the oil inlet 4 and the oil cover of the cleaning port 14, close the drain valve 21 and the oil outlet valve 28, and fill the oil storage tank 1 with oil; close the oil cover of the oil inlet 4 and the oil outlet. Cleaning port 14 oil cover;

[0026] b. Move the oil storage tank 1 to the front of the engine compartment of the automobile, and when the oil storage tank 1 moves to the desired position, press down the brake lever 18;

[0027] c. Turn on the power button of the device, and the system is powered on;

[0028] d. Set the oil filling amount and flow: according to the required oil amount and required oil filling time of the model, set the oil filling amount and flow through the adjustment knob of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com