Drive wheel end face drive finish turning clamp for bevel gear

A technology of driving wheels and bevel gears, which is applied in the field of driving wheel processing and manufacturing, can solve the problems of inability to stably guarantee the runout tolerance and shaft diameter size, low production efficiency, and high cost, and achieve the goals of ensuring dimensional accuracy, convenient clamping, and avoiding interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples, but the present invention is not limited.

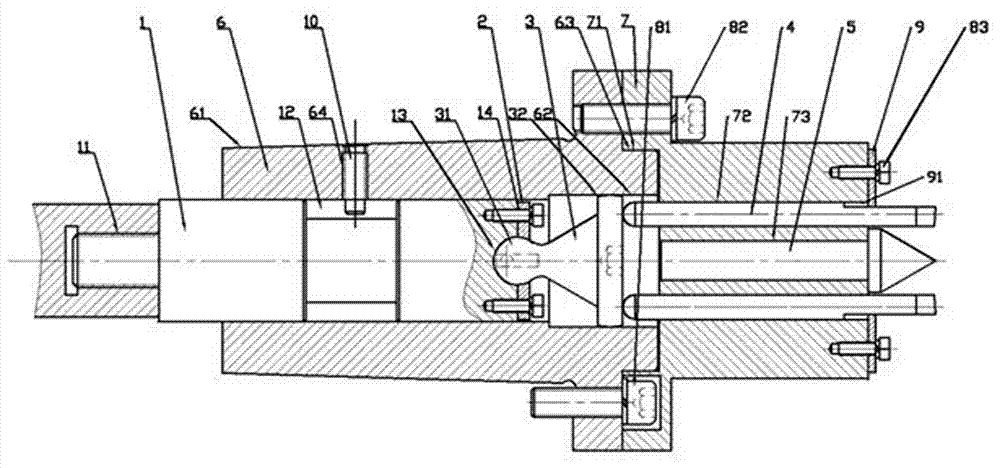

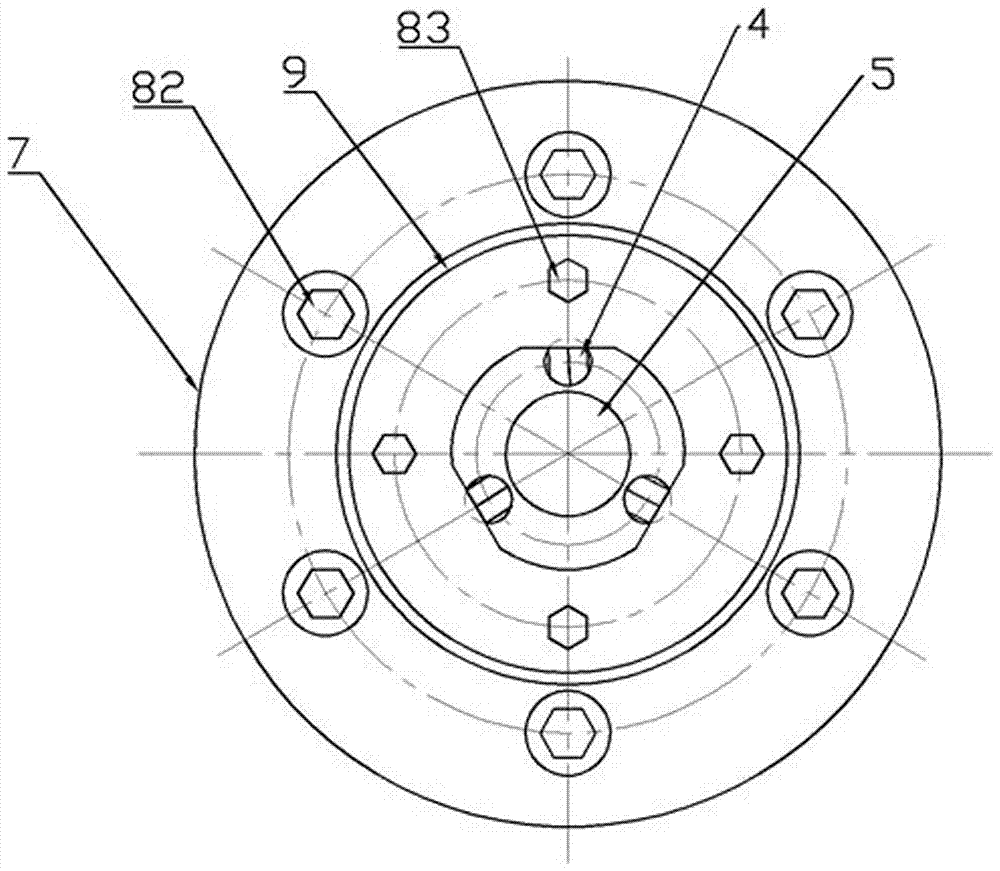

[0022] figure 1 , figure 2 Shows the front view section of the structure of the present invention, a fixture for bevel gear driving wheel end face driving finishing, including connecting rod 1, cover plate 2, push plate 3, driving pin 4, top 5, clamp body 6, front Cover 7, the clip body 6 is connected with the front cover 7, the driving pin 4 and the top 5 are respectively matched with the driving pin hole 72 and the inner cavity 73 of the front cover 7, and the connecting rod 1 passes through the The cover plate 2 is connected with the push plate 3 to form a component that reciprocates in the inner cavity 62 of the chuck body 6 to push the driving pin 4 and the tip 5 together to realize the positioning of the workpiece.

[0023] Preferably, the number of said driving pins 4 is 3;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com