Method for preparing CdS quantum dot/Bi2MoO6/graphene composite photocatalyst

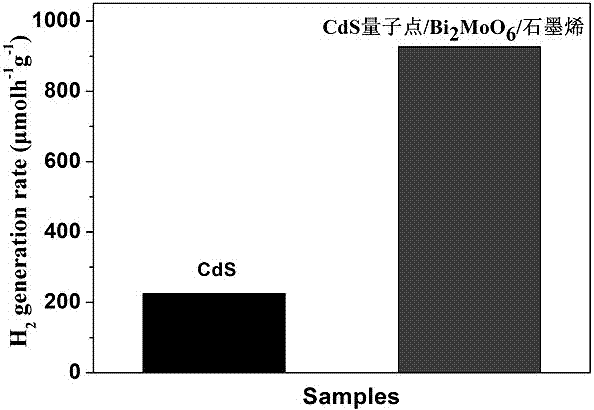

A photocatalyst and graphene technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of high recombination rate of photogenerated carriers, photocorrosion, and low quantum efficiency of photocatalytic hydrogen production and other problems, to achieve the effect of improving hydrogen production efficiency, low degree of agglomeration, and reducing photoetching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Under stirring conditions, dissolve 0.97g of bismuth nitrate pentahydrate and 0.242g of sodium molybdate dihydrate in 200mL of deionized water to form a mixed solution of bismuth nitrate and sodium molybdate, and combine the bismuth nitrate and sodium molybdate at room temperature. After stirring for 2h, the mixed solution was transferred to the hydrothermal reaction vessel, and then the hydrothermal reaction vessel was placed in a microwave digestion apparatus for microwave reaction at 120°C for 5 minutes. After the reaction was completed, it was cooled, washed, and dried to obtain Bi 2 MoO 6 Nano powder

[0020] (2) Prepare 200mL of 0.01mol / L cadmium acetate solution, add 0.0024mol thioglycolic acid and 0.002mol sodium sulfide to the cadmium acetate solution under stirring and nitrogen to obtain a mixed solution;

[0021] (3) React the mixed solution obtained in step (2) at 65℃ for 2h, and then add 0.135g graphene and 0.001mol of Bi obtained in step (1) 2 MoO 6 Nano pow...

Embodiment 2

[0024] (1) Under stirring conditions, dissolve 1.94g bismuth nitrate pentahydrate and 0.484g sodium molybdate dihydrate in 200mL deionized water to form a mixed solution of bismuth nitrate and sodium molybdate, and combine bismuth nitrate and sodium molybdate at room temperature After stirring for 2h, the mixed solution was transferred to the hydrothermal reaction vessel, and then the hydrothermal reaction vessel was placed in a microwave digestion apparatus for microwave reaction at 120°C for 10 minutes. After the reaction was completed, it was cooled, washed, and dried to obtain Bi 2 MoO 6 Nano powder

[0025] (2) Prepare 200mL of 0.03mol / L cadmium acetate solution, add 0.0072mol thioglycolic acid and 0.006mol sodium sulfide to the cadmium acetate solution under stirring and nitrogen to obtain a mixed solution;

[0026] (3) React the mixed solution obtained in step (2) at 65℃ for 2h, then add 0.135g graphene and 0.002mol of Bi obtained in step (1) 2 MoO 6 Nano powder obtains a sus...

Embodiment 3

[0029] (1) Under stirring conditions, dissolve 0.97g of bismuth nitrate pentahydrate and 0.242g of sodium molybdate dihydrate in 200mL of deionized water to form a mixed solution of bismuth nitrate and sodium molybdate, and combine the bismuth nitrate and sodium molybdate at room temperature. After stirring for 2h, the mixed solution was transferred to the hydrothermal reaction vessel, and then the hydrothermal reaction vessel was placed in a microwave digestion apparatus for microwave reaction at 120°C for 30 minutes. After the reaction was completed, it was cooled, washed, and dried to obtain Bi 2 MoO 6 Nano powder

[0030] (2) Prepare 200mL of 0.05mol / L cadmium acetate solution, add 0.012mol thioglycolic acid and 0.01mol sodium sulfide to the cadmium acetate solution under stirring and nitrogen to obtain a mixed solution;

[0031] (3) React the mixed solution obtained in step (2) at 65℃ for 2h, and then add 0.1g graphene and 0.001mol of Bi obtained in step (1) 2 MoO 6 Nano powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com