Nanometer grade extract wall breaking technology

An extract, nano-level technology, applied in the direction of plant raw materials, plant/algae/fungus/moss ingredients, medical preparations containing active ingredients, etc. To solve problems such as large damage to mechanical equipment, it can facilitate the control of grinding parameters, ensure hygroscopicity and adsorption, and achieve uniform grinding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

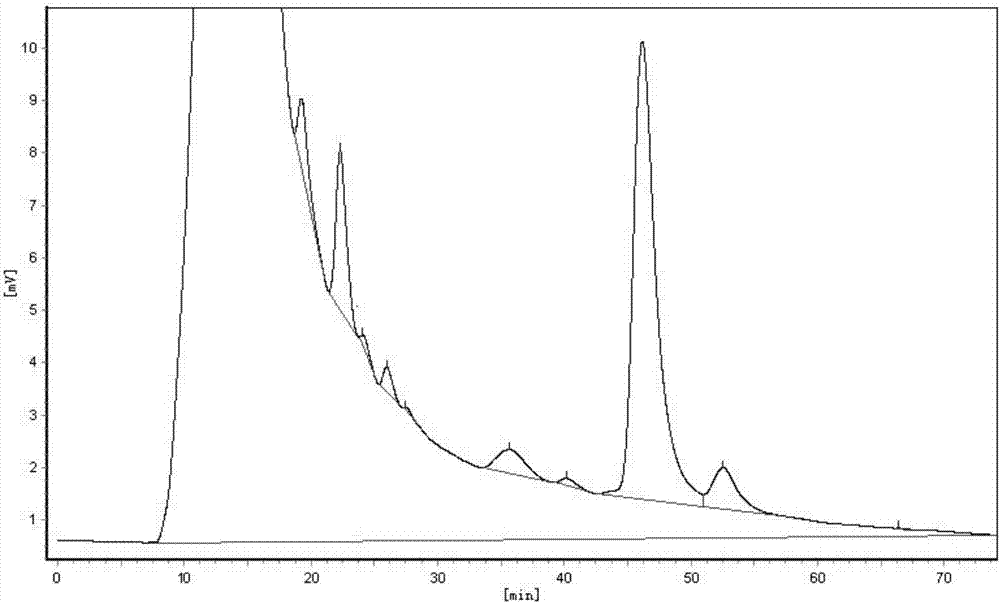

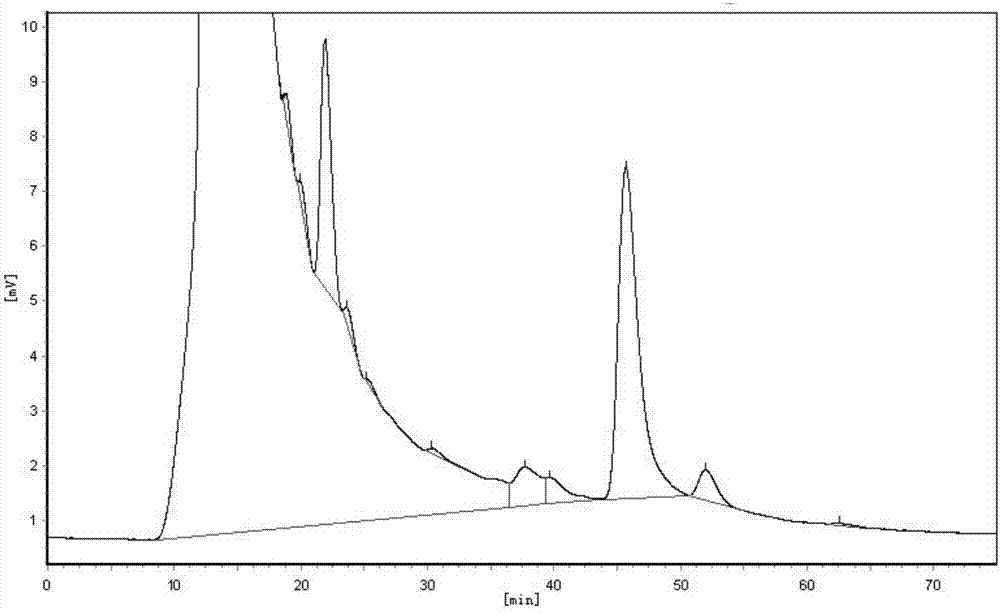

Image

Examples

Embodiment 1

[0027] A nanoscale extract wall-breaking technology, comprising the following steps:

[0028] (1) Dry the ginseng in the sun or dry it at 50°C to keep the water content at 5%; in this step, if the water content is too high after drying, it is not conducive to the crushing of ginseng, and if the water content is too low, the ginseng powder with small particle size will be agglomerated , reduce the dispersibility of the powder.

[0029] (2) Put the dried ginseng in a grinder and carry out rough grinding at 1000r / min, so that the D50 of ginseng powder is lower than 2mm, pass through a 10-mesh sieve after rough grinding, and mix the ginseng fiber particles with the small powder Sieve to facilitate the secondary drying of fiber particles.

[0030] (3) Finely grind the ginseng powder that has passed through a 10-mesh sieve in step (2) at 1000 r / min, so that the D90 of the ginseng powder is lower than 0.1 mm.

[0031] (4) Carry out secondary drying to the fiber particle that has no...

Embodiment 2

[0037] A nanoscale extract wall-breaking technology, comprising the following steps:

[0038] (1) Dry the puerariae naturally or dry it at 60°C, and keep the water content at 4%; in this step, if the water content is too high after drying, it is not conducive to the pulverization of the puerariae root, and if the water content is too low, it will lead to pueraria powder with small particle size Agglomeration reduces the dispersibility of the powder.

[0039] (2) Put the dried kudzu root in a grinder and carry out coarse grinding at 1500r / min, so that the D50 of the kudzu root powder is lower than 2mm, pass through a 10-mesh sieve after the rough grinding, and sieve the kudzu root fiber particles and the powder with a small particle size Separated to facilitate secondary drying of fiber particles.

[0040] (3) Finely grind the kudzu root powder that has crossed a 10 mesh sieve in step (2) at 1500r / min, so that the D90 of the kudzu root powder is lower than 0.1mm.

[0041] (4)...

Embodiment 3

[0045] A nanoscale extract wall-breaking technology, comprising the following steps:

[0046] (1) Dry the licorice in the sun or dry it at 55°C to keep the water content at 4.5%; in this step, if the water content is too high after drying, it is not conducive to the crushing of the medicinal materials, and if the water content is too low, the licorice powder with small particle size will be agglomerated , reduce the dispersibility of the powder.

[0047] (2) Place the dried licorice in a grinder and carry out rough grinding at 1200r / min, so that the D50 of the licorice powder is lower than 2mm, pass through a 10-mesh sieve after rough grinding, and sieve the licorice fiber particles and the powder with a small particle size Separated to facilitate secondary drying of fiber particles.

[0048] (3) Finely grind the licorice powder that has passed through a 10-mesh sieve in step (2) at 1200r / min, so that the D90 of the licorice powder is lower than 0.1mm.

[0049] (4) Carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com