Method for manufacturing connector

A manufacturing method and connecting body technology, applied in semiconductor/solid-state device manufacturing, printed circuit manufacturing, equipment for manufacturing conductive/semiconductive layers, etc., can solve problems such as alignment deviation, narrowing of spacing, short-circuit connection, etc., Achieve the effect of preventing misalignment and suppressing poor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

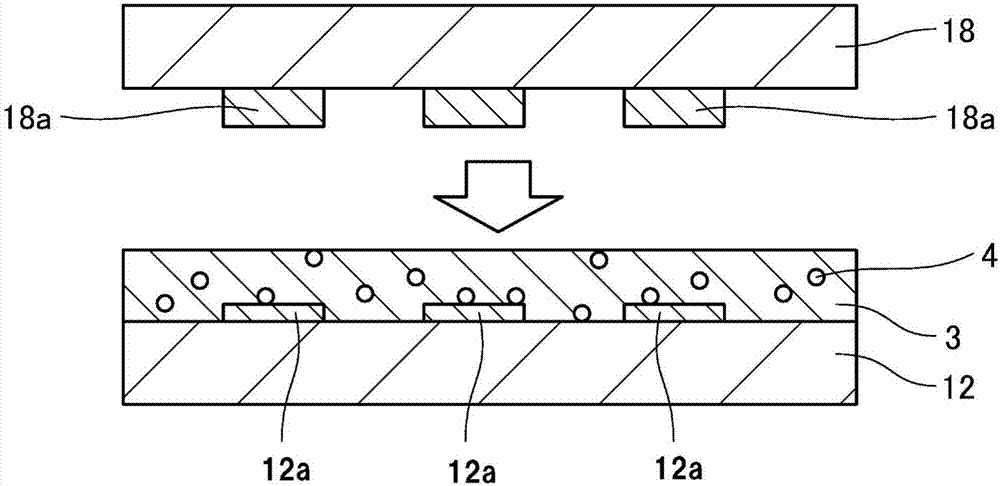

[0075] An anisotropic conductive film was arranged on the evaluation substrate, and an IC for evaluation was arranged on the evaluation substrate through the anisotropic conductive film. Using an ultraviolet irradiator (ZUV-C30H: manufactured by Omron Corporation), ultraviolet rays were irradiated from the disposed evaluation IC side (step (C)), and provisional crimping was performed. After provisional crimping, from the IC side for evaluation, thermal pressurization was performed with a thermocompression bonding tool, and ultraviolet rays were irradiated with an ultraviolet irradiator (step (D)), and main crimping was performed to obtain a connected body sample.

[0076] The amount of ultraviolet radiation during temporary crimping is set to 200mJ / cm 2 . In addition, the actual pressure bonding conditions were 100° C., 80 MPa, and 5 seconds. When pressing, a Teflon (registered trademark) sheet with a thickness of 50 μm was used as a buffer between the thermocompression bondi...

Embodiment 2

[0080] Changed the amount of UV irradiation during temporary crimping to 600mJ / cm 2 , except that, a linker sample was obtained under the same conditions as in Example 1.

Embodiment 3

[0082] Connected body samples were obtained under the same conditions as in Example 1, except that the ultraviolet illuminance and irradiation time during provisional crimping were changed, and only thermal pressing was performed during main crimping without ultraviolet irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com