A kind of special reagent for sludge treatment and using method thereof

A sludge treatment and reagent technology, which is applied in the field of special reagents for sludge treatment, can solve the problems of high water content in sludge, long cycle of repeated development and utilization, poor engineering properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

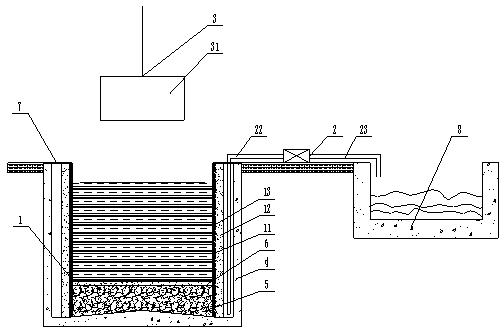

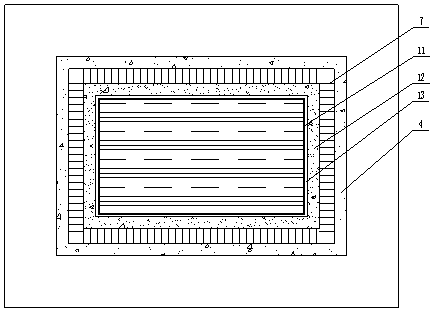

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] During specific implementation: if figure 1 with figure 2 As shown, a special reagent for sludge treatment is characterized in that the composition and mass ratio of the special reagent are 120-300 parts of cement, 250-500 parts of quicklime, 0.5-3.0 parts of aluminum powder, and 3-3 parts of water reducing agent. 6 parts, quick setting agent 5~10 parts and foam stabilizer 0.02~0.1 parts.

[0032]In this technical solution, the cement in the special reagent can reduce the hydrophilicity of the sludge, increase the hardness and brittleness of the sludge, and increase the strength of the sludge; pollution; aluminum powder can foam the silt, generate a large number of air bubbles when the silt hardens, form a large number of connected pores, form a rope head channel, and increase the permeability of the silt; the water reducer can increase the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com