Method for synthesizing 4-nitro diphenylamine and 4-nitroso diphenylamine or/and their salts

A technology of nitrosodiphenylamine and nitrodiphenylamine, which is applied in the field of synthesis of organic matter, can solve the problems of high water control requirements, small processing capacity, and difficult effective control, so as to speed up the dehydration rate and increase the forced heat exchanger , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

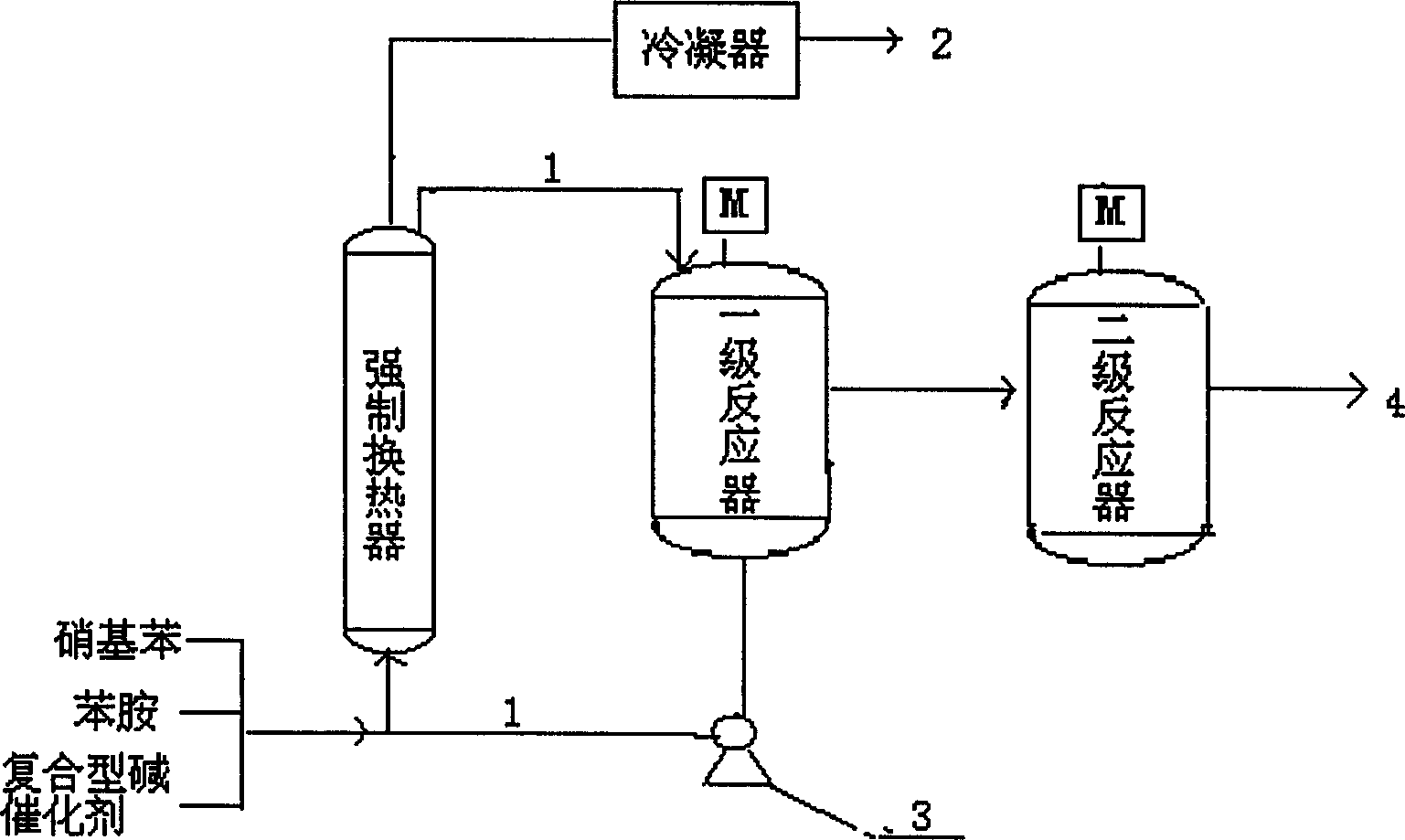

Image

Examples

Embodiment Construction

[0020] Simultaneously open composite catalyst, aniline and nitrobenzene delivery pumps, adjust the flow rate to 150 kg / hour of aniline, 30 kg / hour of nitrobenzene, composite alkali catalyst (its components are composed of tetramethylammonium hydroxide, sodium hydroxide and the aqueous solution composed of tetramethylammonium carbonate, the sum of the concentration of the three is 29.9%, and the molar ratio of the three is 1:1:0.5) 80 kg / hour, continuously enters the forced heat exchanger, and the heat medium of the forced heat exchanger Alcohol steam is used to force the condensed liquid in the heat exchanger into the primary reactor from the top, continue to dehydrate and react, then open the bottom valve of the primary reactor and the condensation circulation pump, and adjust the outlet valve of the condensation circulation pump to make the material return Into the forced heat exchanger, a local circulation system is formed, so that the material is continuously circulated, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com