Method for preparing vegetable core clear soup

A processing method and a technology for cabbage, which are applied in the field of processing and production of ready-to-eat vegetables in soup, can solve the problems that the rehydration performance of color, flavor and flavor cannot meet the requirements of consumers, the effect of greening and color protection is poor, and the production cycle is shortened. The effect of dehydration rate, increasing the weight of cabbage and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

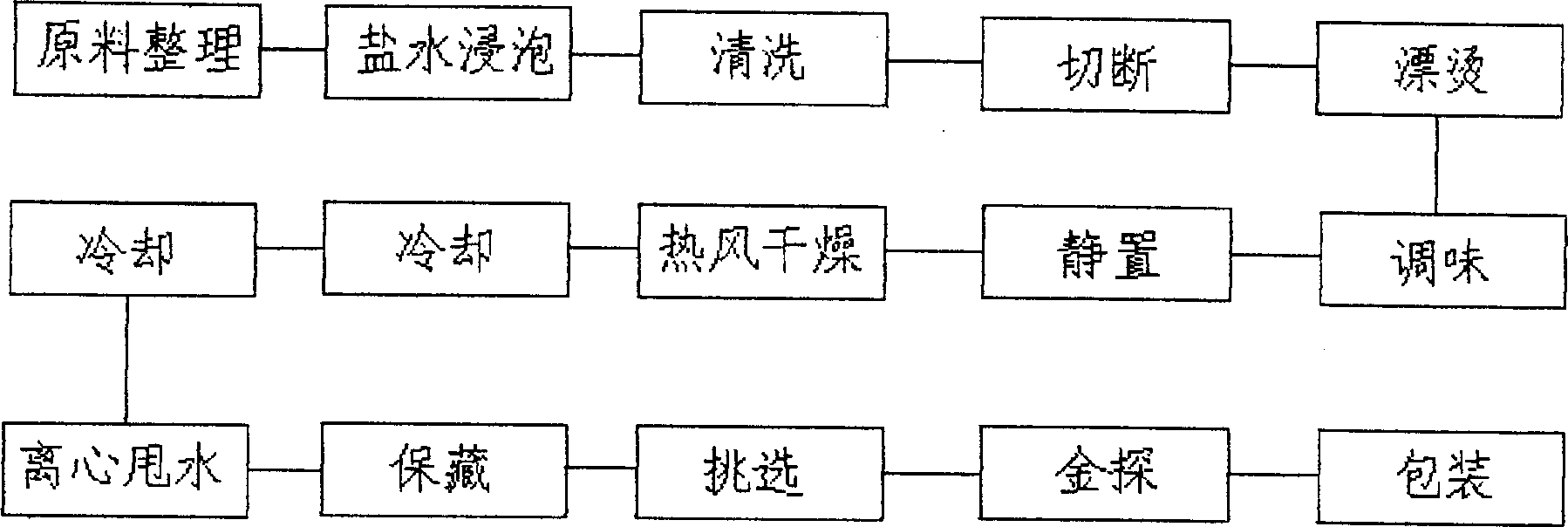

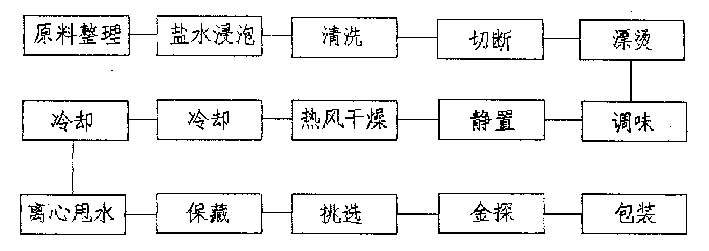

[0017] Embodiment: see accompanying drawing.

[0018] Raw material arrangement: use "Ai Kangqing", "Aijiaoqing", "Youdong'er" and other rapeseed varieties as raw materials, and take the middle and side main mustard parts that germinate in spring, and require that the raw materials have no buds and green color To dark green, the tissue is fresh and tender, no peculiar smell, no impurities. Remove weeds, different vegetables, insect snails and other sundries for fresh raw materials delivered on the same day.

[0019] Soaking in salt water: Immerse the cabbage heart in 1.2 salt water to repel insects and make it greener.

[0020] Cleaning: Rinse with clean tap water to remove the salt and some impurities attached to the cabbage.

[0021] Cutting: Use a knife to cut off neatly according to the specification, the specification is: 40 plus or minus 10 mm.

[0022] Blanching: Submerge the Chinese cabbage in water at 90-95 degrees Celsius for about 2 minutes, until the Chinese cabb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com